A corrugated paper flattening conveyor frame

A conveyor frame and corrugated paper technology, which is applied in the directions of transportation and packaging, thin material processing, machining/deformation, etc., can solve the problems of affecting product quality, high labor intensity of operators, and low work efficiency, so as to improve the flattening effect, Eliminate the effect of being too holistic and flattening

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

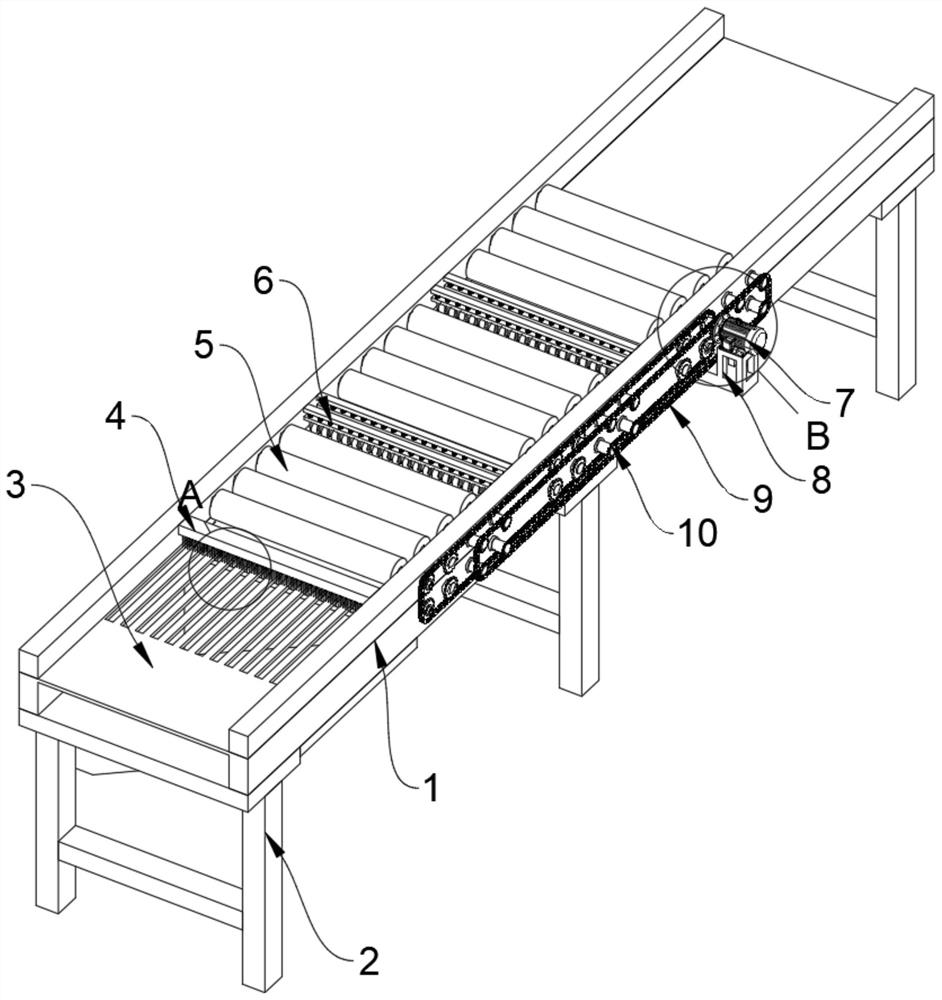

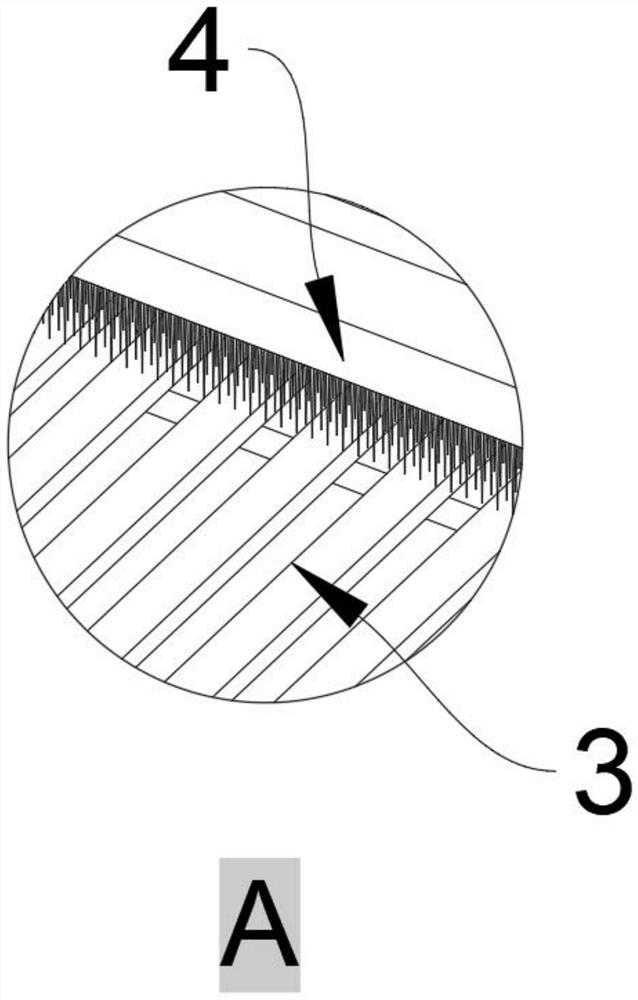

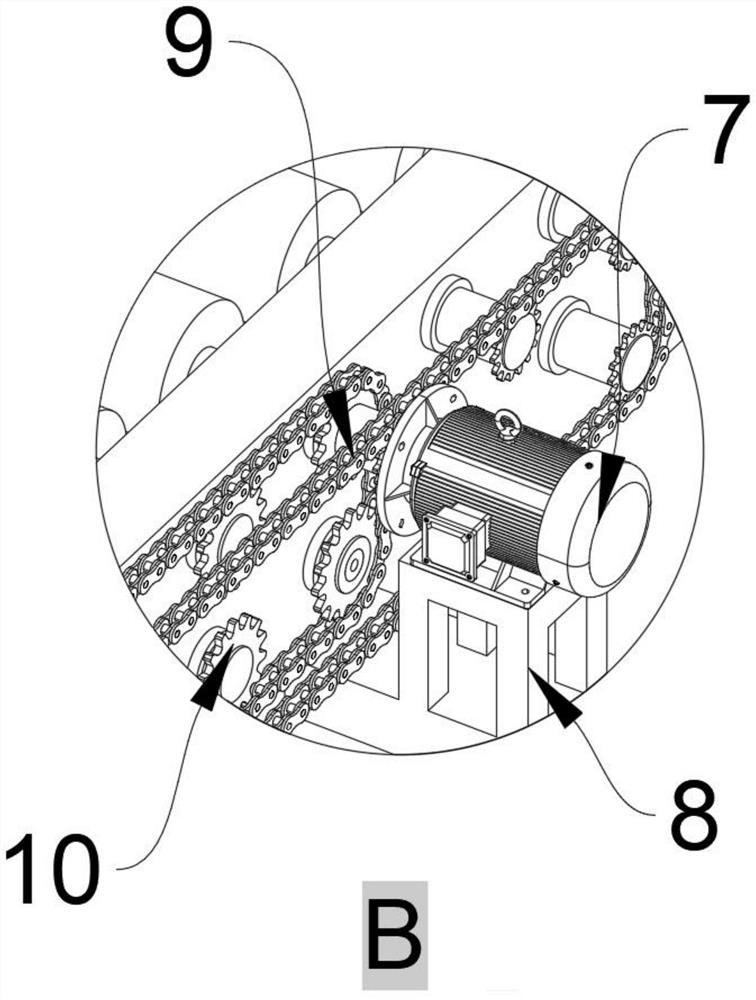

[0040] as attached figure 1 to attach Figure 10 Shown:

[0041]The present invention provides a corrugated paper flattening conveying frame, comprising: a fixed frame 1, a motor fixed frame 8 and a drive chain 9; the bottom side of the fixed frame 1 is fixedly provided with support legs 2; the motor fixed frame 8 is welded and fixed to the fixed frame 1 On the outer wall of the motor holder 8, the drive motor 7 is fixed with bolts; there are two drive chains 9, and the drive chain 9 and the drive gear 10 are designed to fit each other, and the drive motor 7 is connected to the display through the drive chain 9. The flattening rollers 5 are connected by transmission, and there are three groups of flattening rollers 5, and each group of flattening rollers 5 is provided with a total of four, and the three groups of flattening rollers 5 are equidistantly arranged and rotated on the fixed frame 1. On the inner side wall, it is convenient to flatten the corrugated paper shell mul...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com