Through bolt assembling structure for square steel binding post and square steel tubular beam

A technology for assembling structures and connecting columns, applied in building structures, buildings, etc., can solve problems such as complex on-site operations and imperfect structural design, and achieve the effect of simplifying structural design, good limit rotation ability, and ensuring architectural aesthetics.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

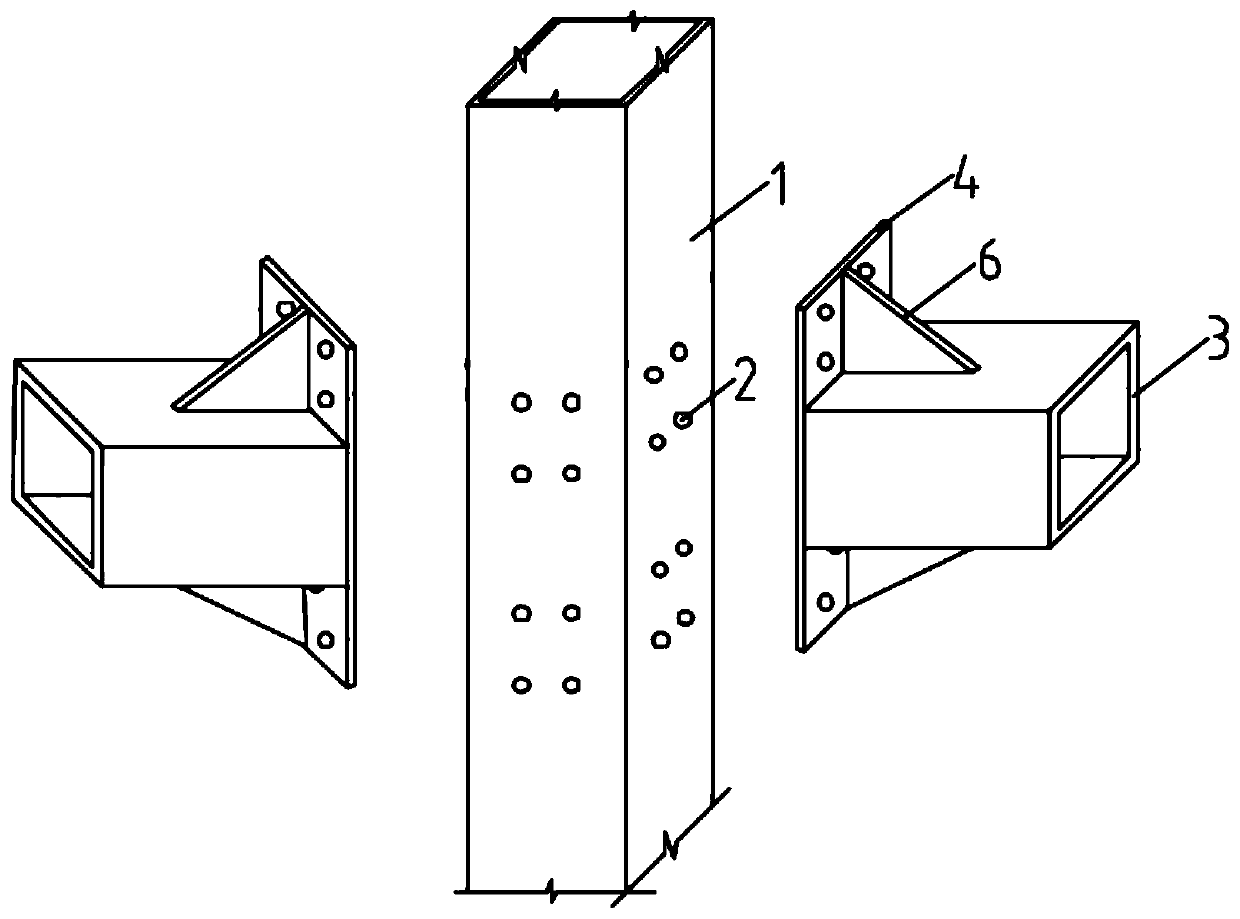

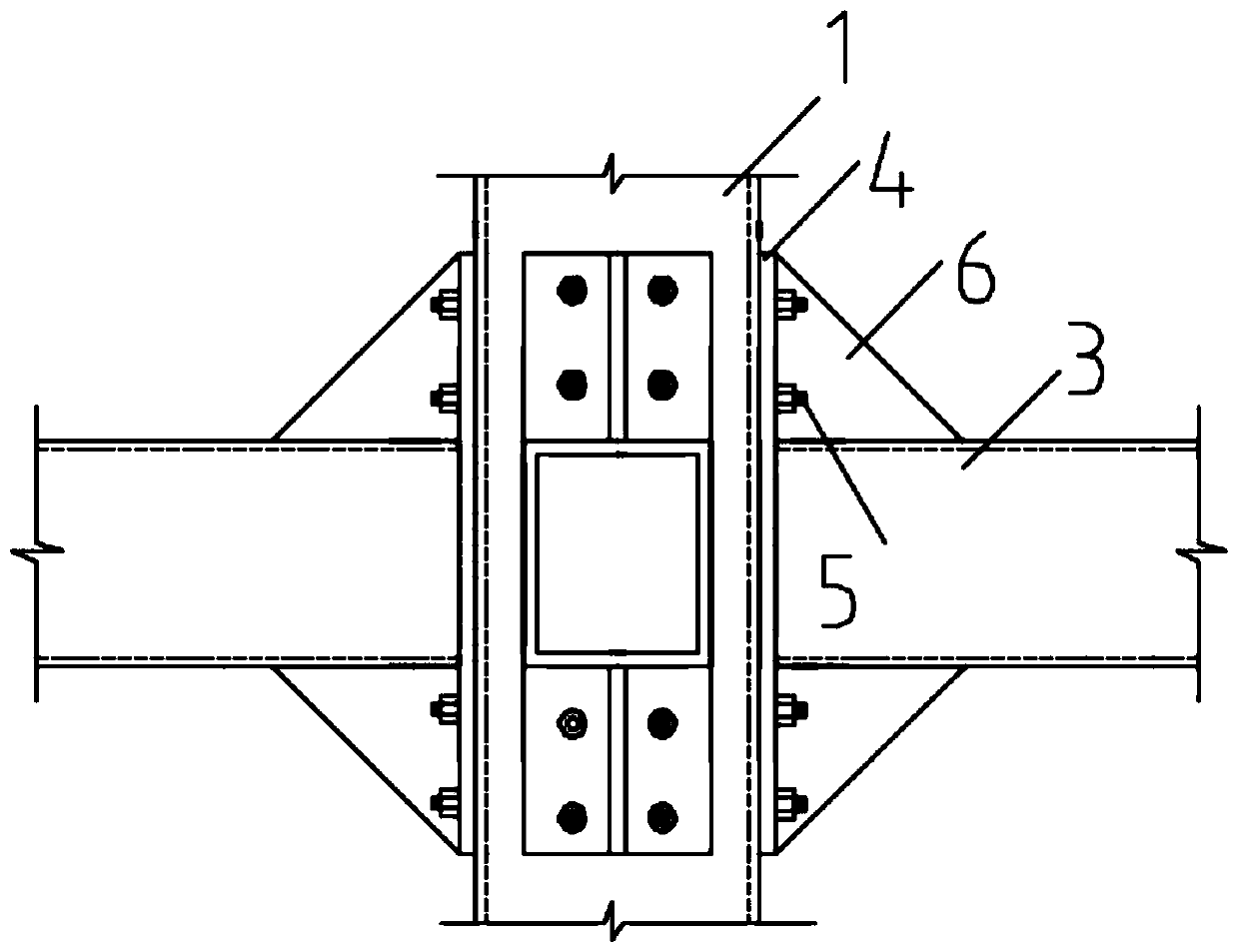

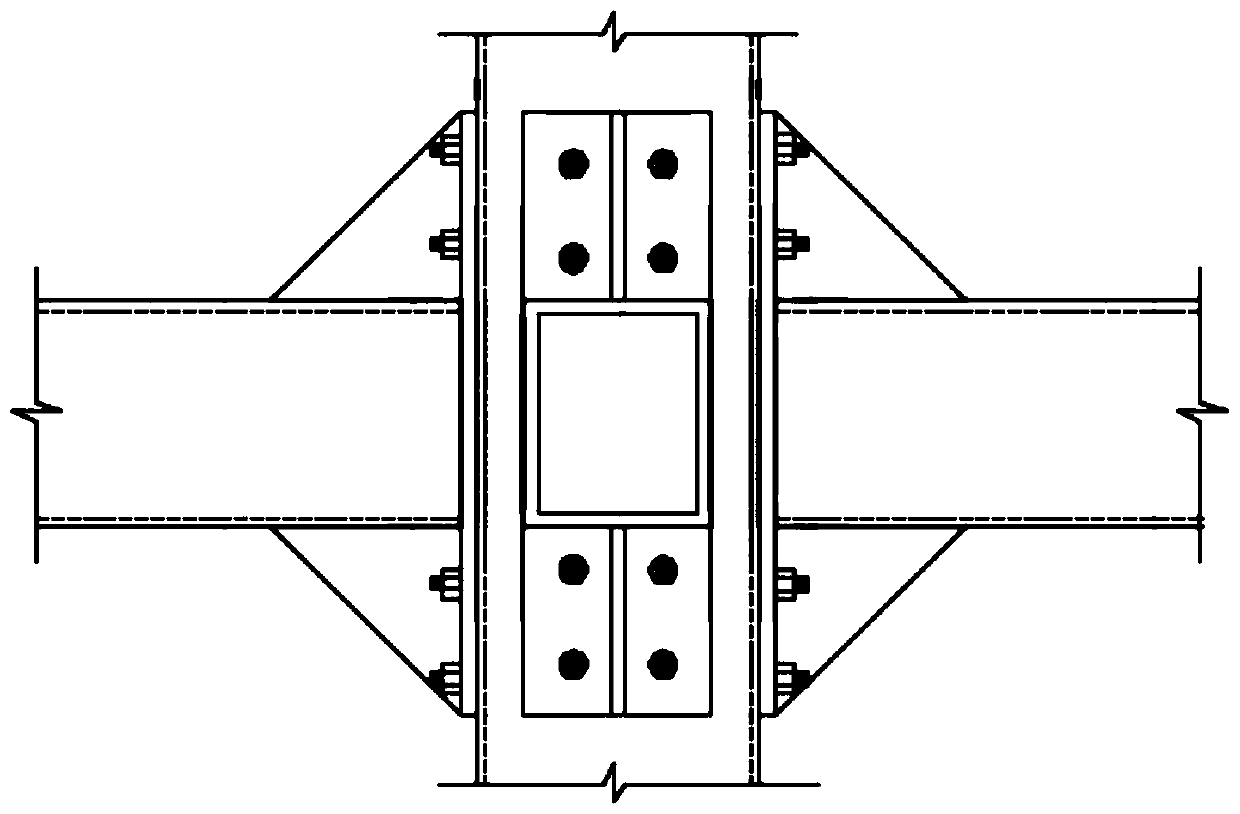

[0021] Example 1: Please refer to Figure 1-5 , a through-bolt assembly structure of a square steel connecting column and a square steel pipe beam, comprising a bolt connection hole 2 provided on a square steel pipe beam 1, the connecting end of the square steel connecting column 3 is fixedly connected with an end plate 4, and the end plate 4 Open the bolt connection hole 2 that matches the bolt connection hole 2 on the square steel pipe beam 1. The square steel pipe beam 1 and the end plate 4 are connected by threaded bolts 5 passing through the bolt connection hole 2. By placing a nut in the square steel pipe beam 1, the Threaded bolts for connection.

[0022] The end plate 4 is welded to the square steel connecting column 3 .

[0023] The bolt connection holes 2 are symmetrically arranged on the end plate 4 .

[0024] The bolt connection holes 2 are evenly distributed on the four corners of the end plate 4 .

[0025] A rib plate 6 is connected between the square steel co...

Embodiment 2

[0028] Embodiment 2: This embodiment is a further improvement of the previous embodiment: the threaded pipe can be pre-embedded in the bolt connection hole 2 of the square steel pipe beam 1, and then the threaded bolt 5 can be used to directly penetrate the bolt connection hole 2 and then be connected with the threaded pipe. can be fixed.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com