Waterflood simulation recovery ratio test method considering energy flow in low-permeability reservoir

A technology of energy flow and testing method, applied in the directions of measurement, production of fluids, and earth-moving drilling, etc., can solve the problems of uneven distribution of irreducible water, influence of experimental accuracy, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

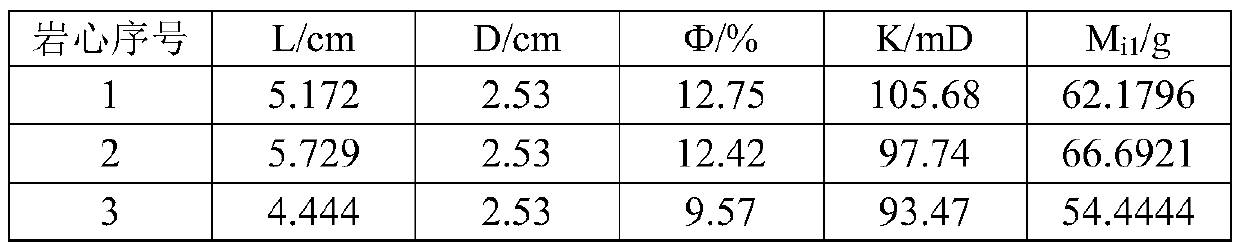

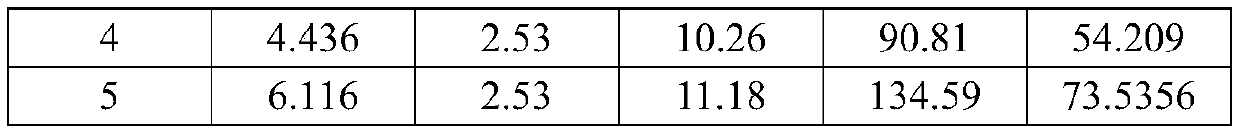

Embodiment 1

[0018] In this example, the original formation pressure is 15MPa, the formation temperature is 50°C, the current formation pressure is 10MPa, the simulated oil viscosity is 5.04mPa·s, and the simulated crude oil volume coefficient is 1.197ml / ml.

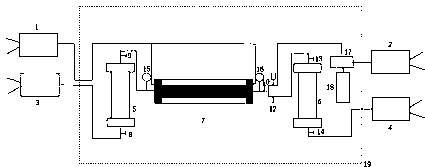

[0019] A water injection huff and puff recovery test method considering energy flow in low-permeability reservoirs, which is completed by a core displacement device, which consists of a confining pressure pump 1, a core holder 7, a back pressure pump 2, an oil-water separator 18, a simulation Oil intermediate container 5, displacement pump 1 3, formation water intermediate container 6, displacement pump 2 4, and constant temperature box 19, the core holder 7 is connected to confining pressure pump 1, and its inlet port is connected to simulated oil intermediate container 5 and the displacement pump one 3, the outlet end is respectively connected to the back pressure valve 17 and the formation water intermediate container 6, the format...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com