Double-tube-plate cooling air pipe system of high-temperature air preheater

A technology of air preheater and cooling air duct, which is applied in lighting and heating equipment, combustion methods, indirect carbon dioxide emission reduction, etc., can solve the problem of large occupied area, achieve small occupied area, compact structure, and save occupied area Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

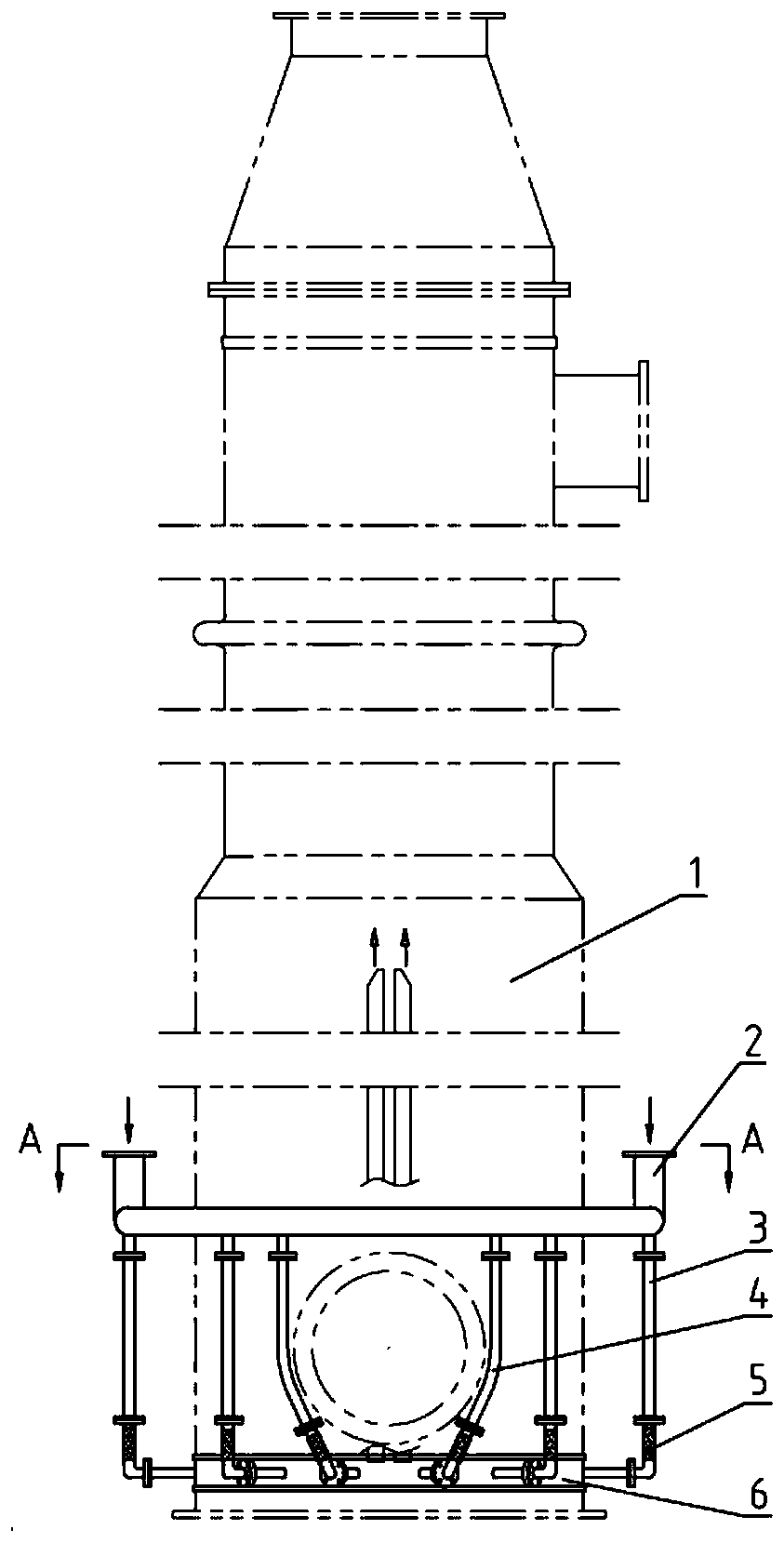

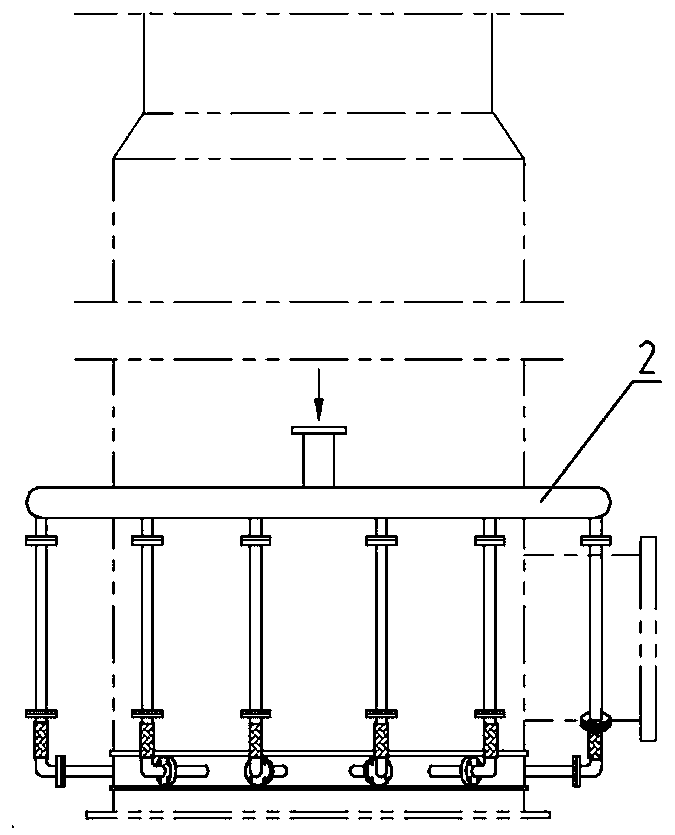

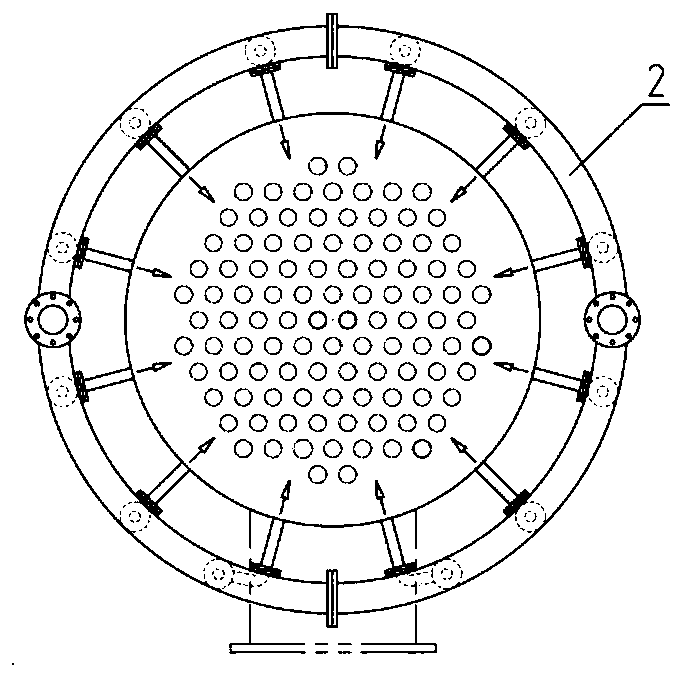

[0027] High-temperature air preheater double tube plate cooling air duct system, including: cold air main pipe 2, intermediate straight pipe 3, intermediate bent pipe 4, right-angle metal hose 5, double tube plate nipple 6.

[0028] When assembling:

[0029] 1. Install the right-angle metal hose 5 on the evenly distributed cold air connection pipe on the double tube plate nipple 6;

[0030] 2. The two right-angle metal hoses 5 under the hot air outlet of the air preheater are inclined outward according to the outer diameter of the hot air outlet pipe;

[0031] 3. The two middle elbows 4 are connected by two metal hoses 5 with inclined lower flanges;

[0032] 4. The lower flanges of other intermediate straight pipes 3 are connected with other right-angle metal hoses 5;

[0033] 5. The upper flanges of all intermediate straight pipes 3 and intermediate bent pipes 4 are connected to the corresponding connecting flanges under the cold air main pipe 2;

[0034] 6. The two flange...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com