Metal pipe flattening test device

A flattening test, metal tube technology, used in measuring devices, using stable tension/pressure to test material strength, instruments, etc. Convenience and simplicity, the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described below in conjunction with accompanying drawing.

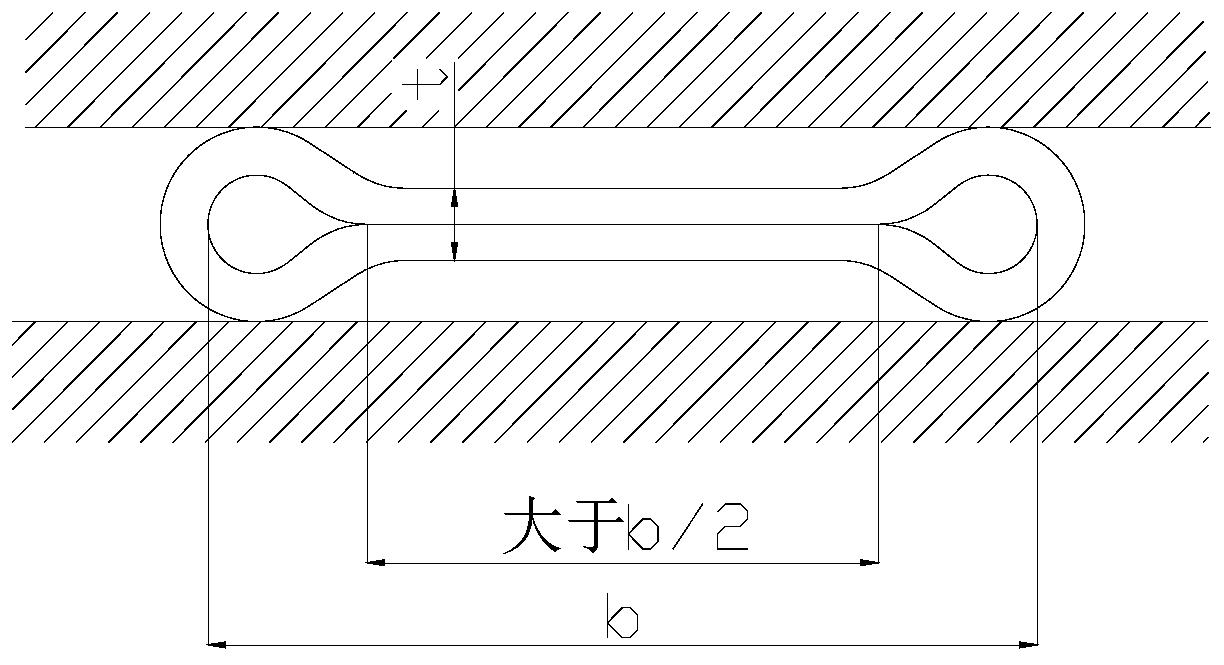

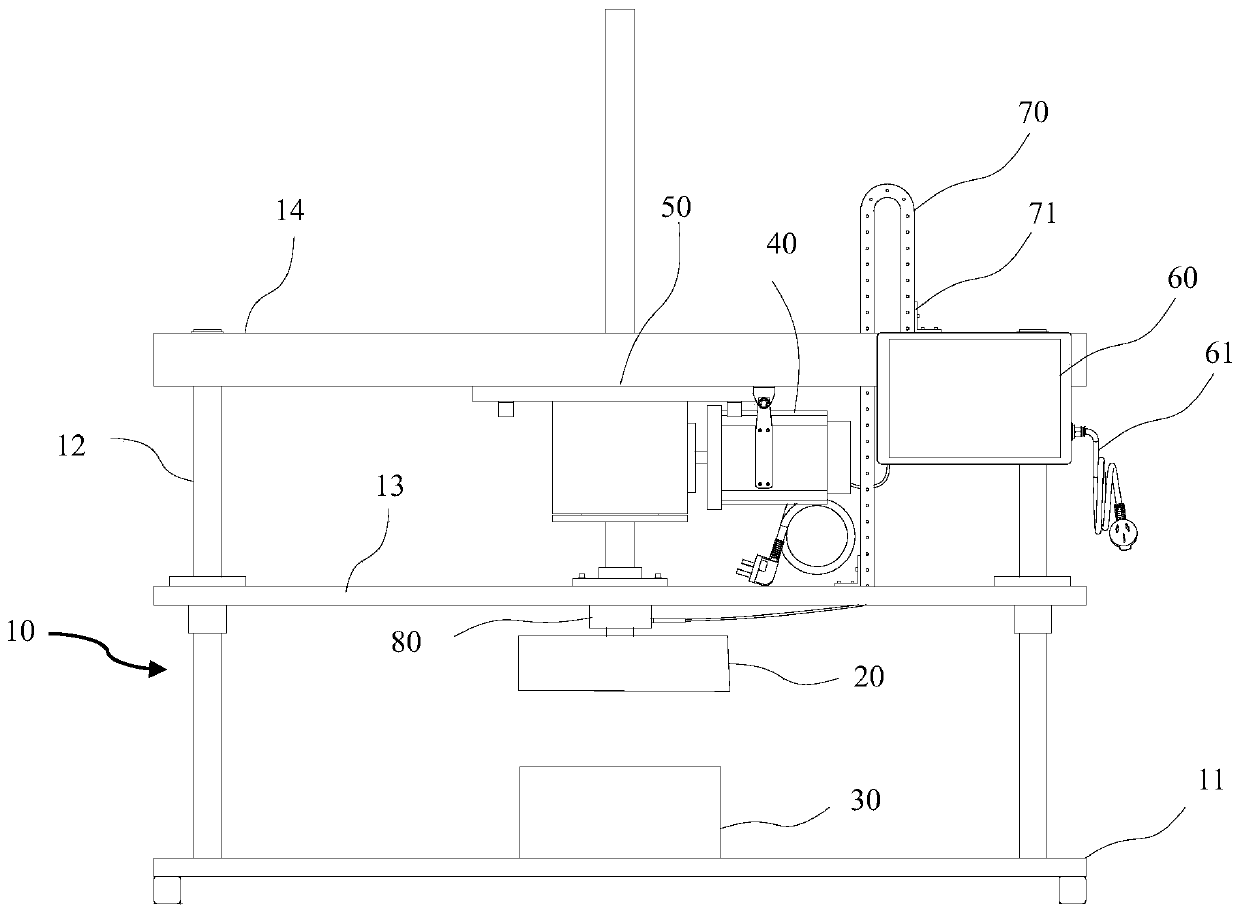

[0024] Such as figure 2 As shown, the metal pipe flattening test device of the present invention includes a frame 10, a driving device arranged on the frame 10, a first pressing plate 20 connected to the driving device, and a second pressing plate 30, the first pressing plate 20 and the second pressing plate 30 are cooperatingly arranged, such as aligned, and a metal tube is arranged between the first press plate 20 and the second press plate 30, for example, the metal tube is arranged on the second press plate 30, and the driving device drives the first press plate 20 to squeeze the metal tube located on the second press plate 30. Metal tube, the extrusion width of first pressing plate 20 and the second pressing plate 30 are preferably all less than the diameter of metal tube, so that metal tube is extruded as figure 1 the shape shown. When the distance t between the tw...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap