High-performance temperature control system for LED wire bonder

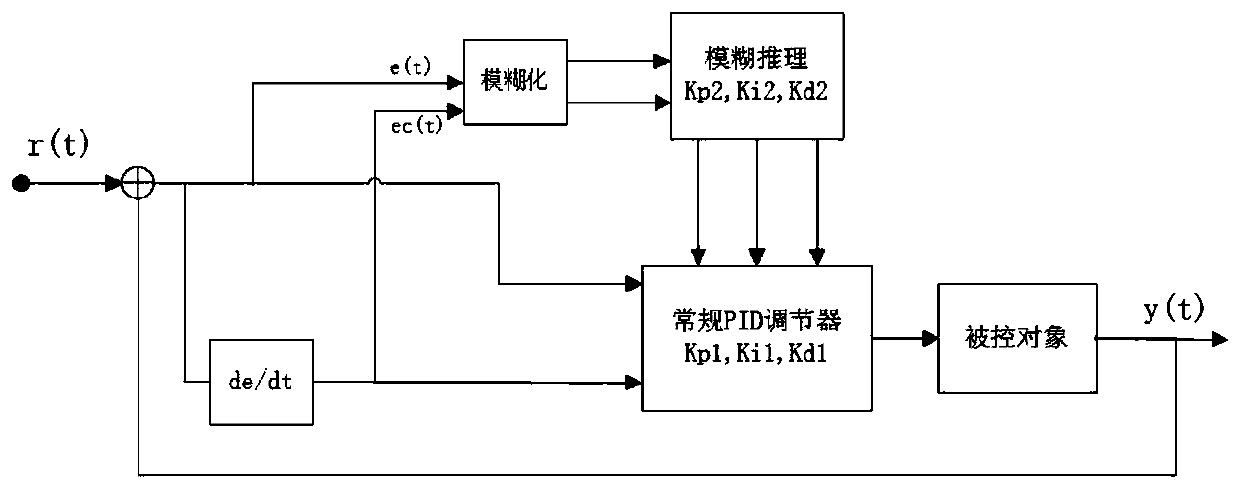

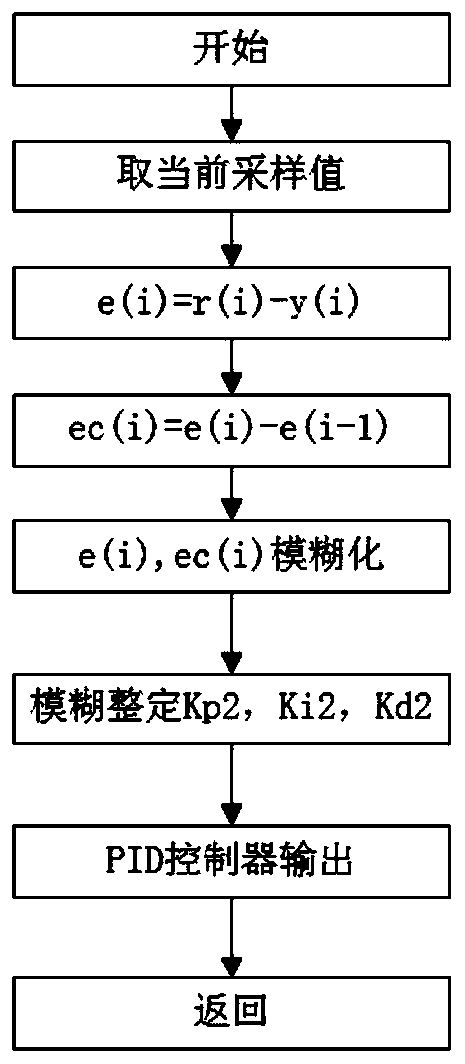

A temperature control system and high-performance technology, applied in the field of wire bonding machines, can solve the problems of large overshoot in the adjustment process, long heating waiting time, uneven temperature distribution on the surface of the heating block, etc., to achieve enhanced adaptability and robustness , Improve the effect of dynamic and static characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The specific implementation of this patent will be described in detail below in conjunction with the accompanying drawings. It should be pointed out that this specific implementation is only an example of the preferred technical solution of this patent, and should not be understood as limiting the scope of protection of this patent.

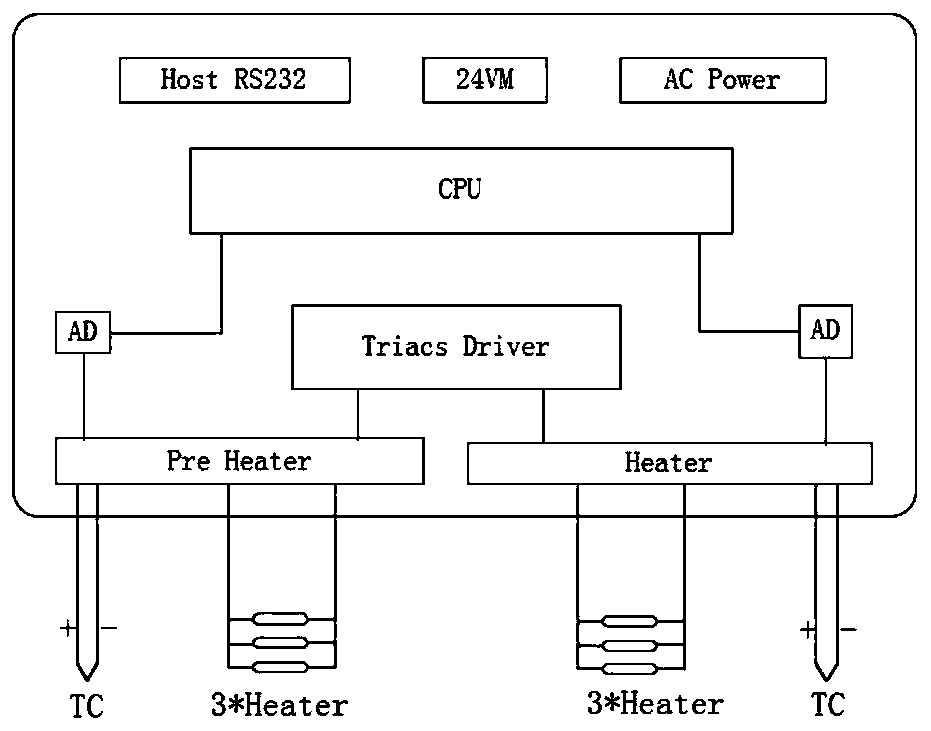

[0015] like figure 1 As shown, this patent provides a high-performance temperature control system for an LED wire bonding machine, the system includes a heating block, a temperature sensor, a heating rod, and a controller.

[0016] Wherein the temperature sensor is arranged between the heating blocks to collect temperature data of the heating blocks, and the temperature sensor is realized by using a thermocouple sensor or other sensors, which have been widely recorded in the art.

[0017] A thermocouple is placed in the middle of the surface of the heating block as a temperature sensor, and the temperature of the heating block is sampled t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com