Variable-working-condition emission performance prediction method for combustion chamber of gas turbine

A technology for emission performance and gas turbines, applied in the direction of design optimization/simulation, etc., can solve the problems of low calculation efficiency and inapplicability, and achieve the effect of ensuring calculation accuracy, ensuring accuracy, and reducing modeling difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention is described in more detail below in conjunction with accompanying drawing example:

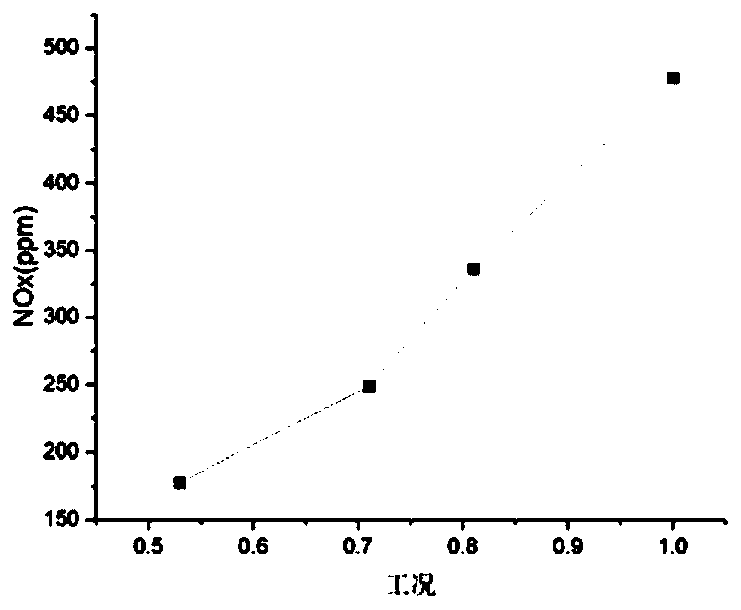

[0034] combine Figure 1-18 , the present invention comprises the following steps:

[0035] The structure of the gas turbine combustion chamber is complex, and modeling is difficult and difficult to calculate. The invention adopts the equivalent area method to simplify the structure of the combustion chamber. The simplification of the combustion chamber includes: in order to reduce the impact of the shell on the calculation results, it is simplified to a cylindrical shape; the flow field in the combustion chamber collector has less influence on the main combustion area, so it is simplified to an axisymmetric cone ; Simplify the cooling holes on the wall of the flame tube, and change the circular holes into square hole ring grooves to ensure the mesh quality and calculation convergence.

[0036] For some working conditions, the simplified combustor model is meshe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com