Device and method for inserting flat wire hairpins into stator

A card-issuing, flat-wire technology, applied in the field of flat-wire motors for new energy vehicles, can solve problems such as motor efficiency discounts, low automation, and difficulty in ensuring product quality stability, and achieve the effect of avoiding scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] It should be noted that, in the case of no conflict, the embodiments in the present application and the features in the embodiments can be combined with each other. The present invention will be described in detail below with reference to the accompanying drawings and examples.

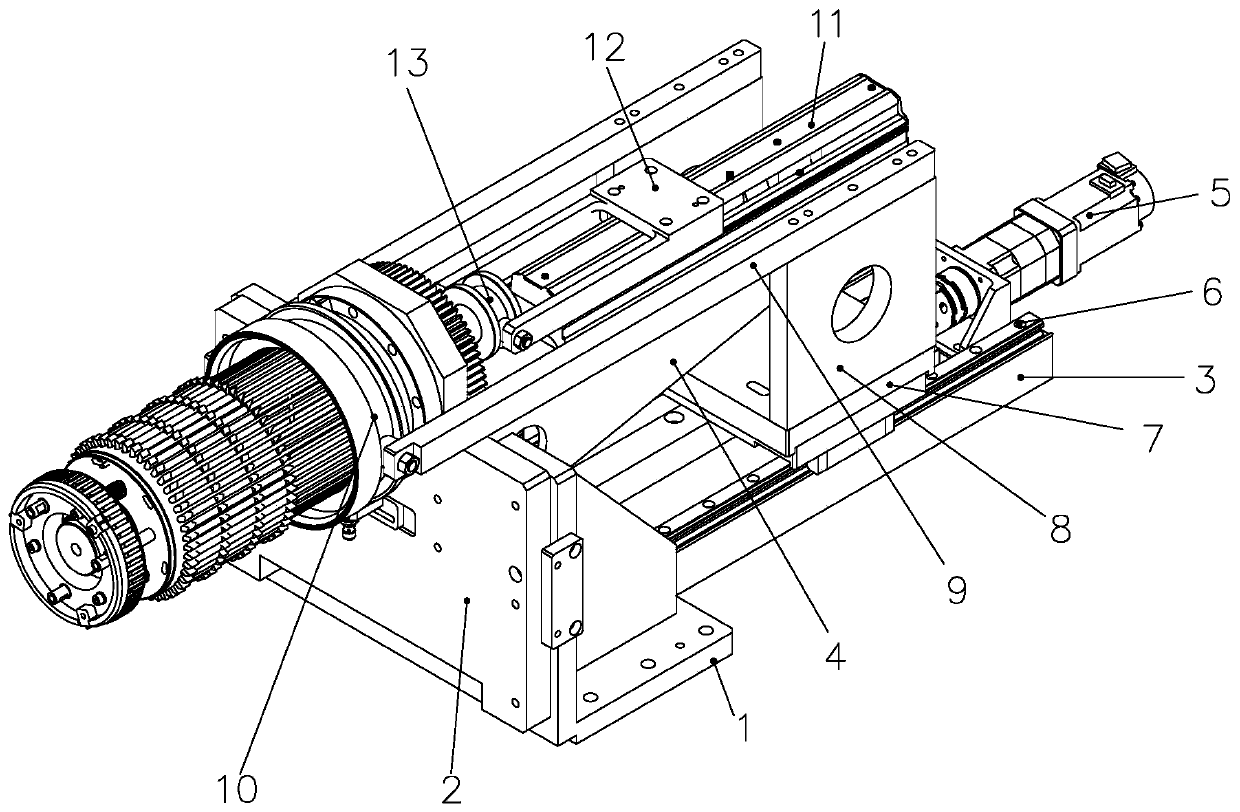

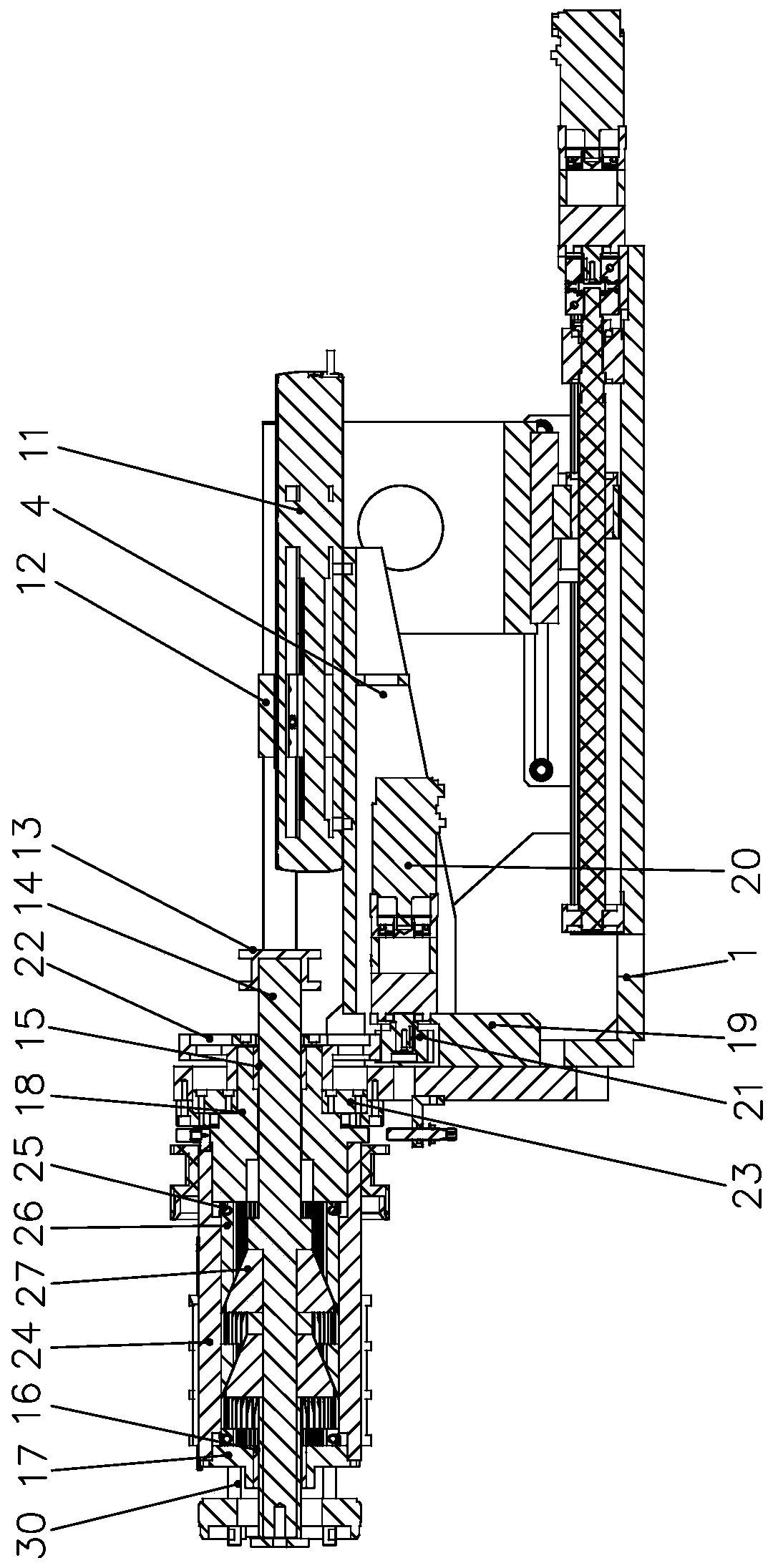

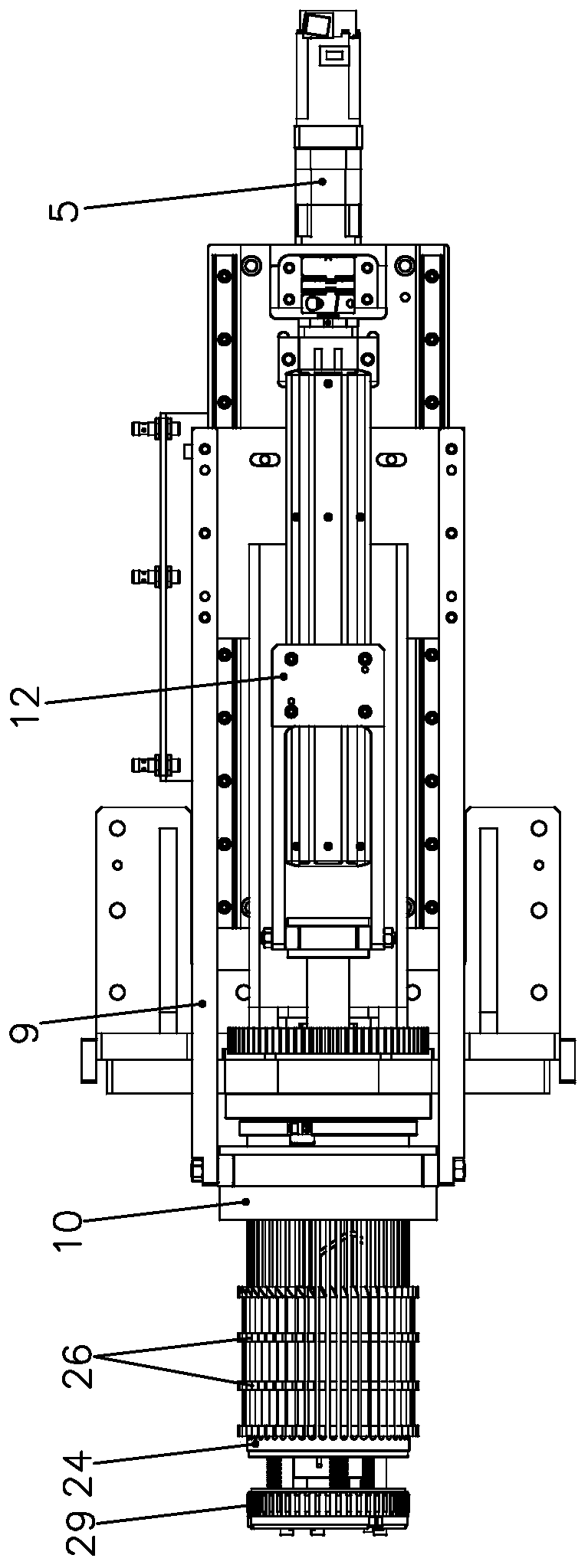

[0035] Figure 1 to Figure 10 Some embodiments according to the invention are shown.

[0036] combined reference Figure 9 to Figure 10 , the method for inserting a flat wire hairpin into a stator of the present invention includes the following steps S1-S5.

[0037] S1. Provide a hairpin placement mold, which includes a barrel 24 and a number of baffles 26 for forming a hairpin placement groove 32 on the outer periphery of the barrel, wherein a number of stops 26 are placed one layer of flat wire hairpin grooves at a time The depth requires extending the barrel one by one.

[0038] S2. Put the flat wire hairpin 50 into the hairpin placement groove 32 on the outer periphery of the material c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com