Correcting device and assembling and correcting method of printer roller

A calibration device, printer technology, applied in the direction of metal processing, metal processing equipment, manufacturing tools, etc., to achieve the effect of improving the stability of handling, improving the quality of press-fit assembly, and improving the efficiency of handling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

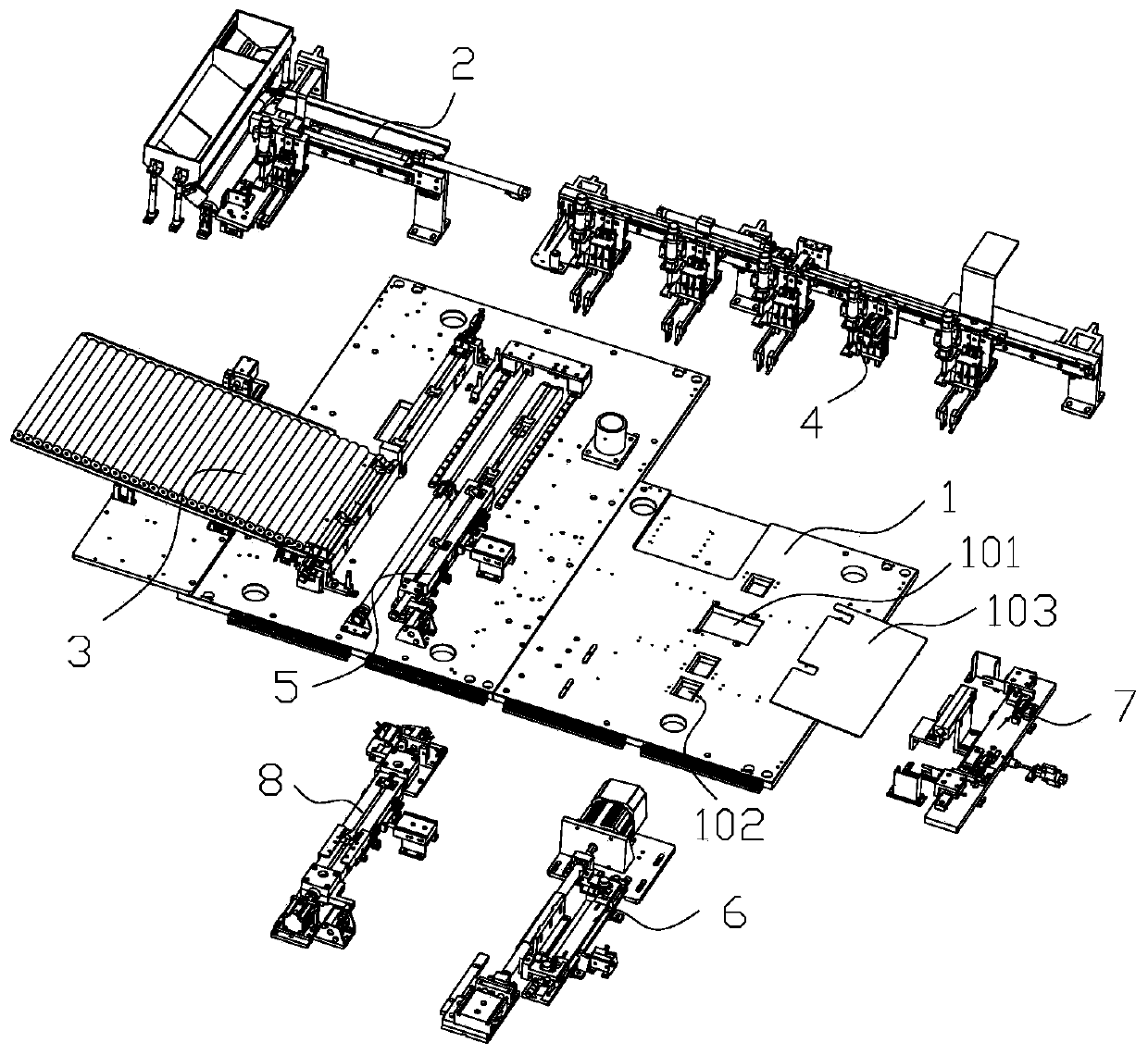

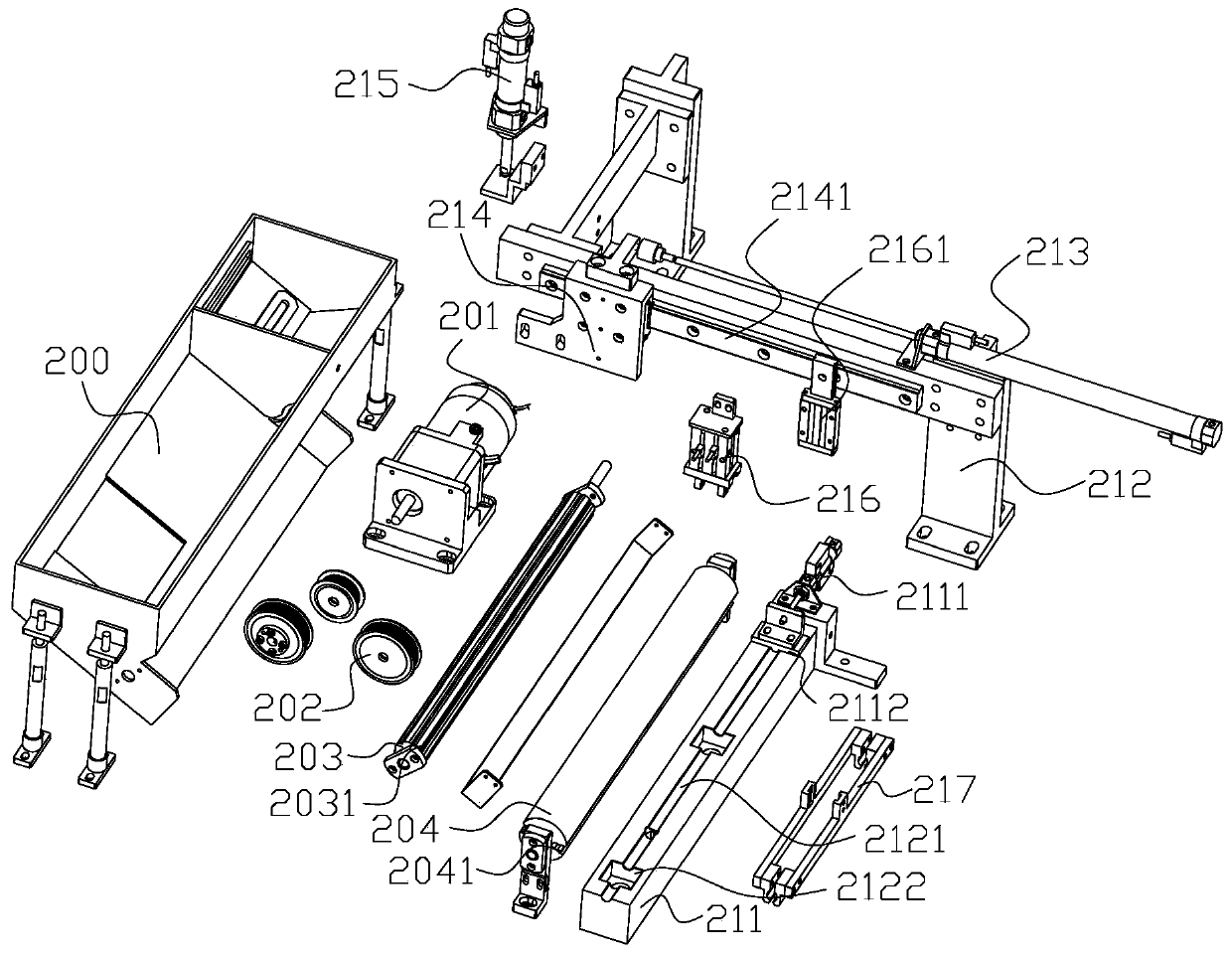

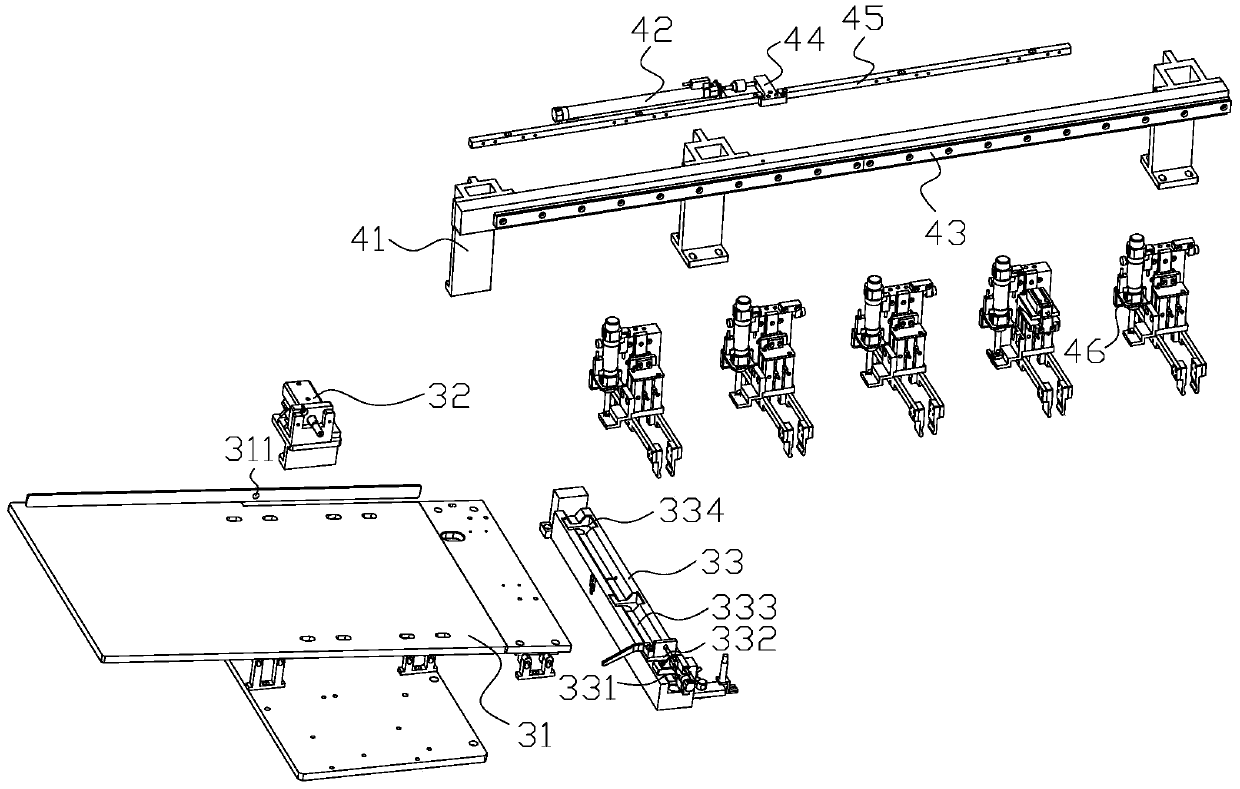

[0025] like figure 1 As shown, a printer roller assembly production equipment includes a frame 1, a shaft feeding and handling device 2, a sponge feeding device 3, a sponge cutting device 6, a shaft end removing device 7, an assembly correction system and a control system; The assembly correction system consists of a sponge transport device 4 , an assembly device 5 and a correction device 8 . The shaft feeding and handling device 2 is arranged at the rear of the frame 1, and the shaft feeding and handling device 2 is used to feed and transport the shaft to the assembly device 5; the sponge feeding device 3, the sponge handling device 4, the assembly device 5, The correction device 8, the sponge cutting device 6 and the shaft end removal device 7 are respectively arranged on the front part of the frame 1, the sponge feeding device 3 is used to feed the shaft, and the sponge handling device 4 is used to transport the sponge to the On the sponge assembly device 5, the sponge cut...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com