Automatic semi-finished food snack processing vehicle and processing method

A technology for semi-finished products and fast food, applied in motor vehicles, goods transport vehicles, heating devices, etc., can solve the problems of high labor intensity, low operation efficiency, low degree of automation of multi-manual operations, and reduce processing personnel and labor intensity. , the effect of reducing the ability of food supply security

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

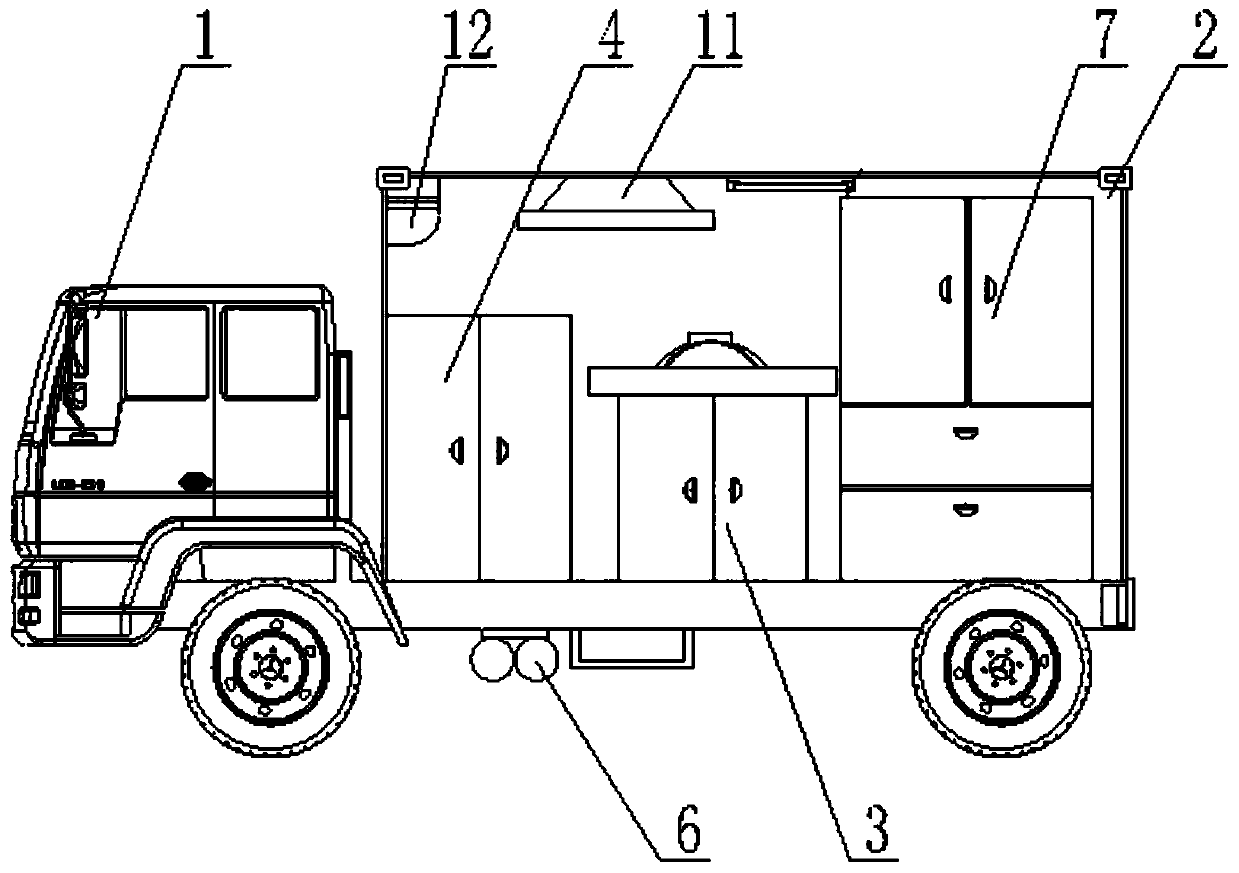

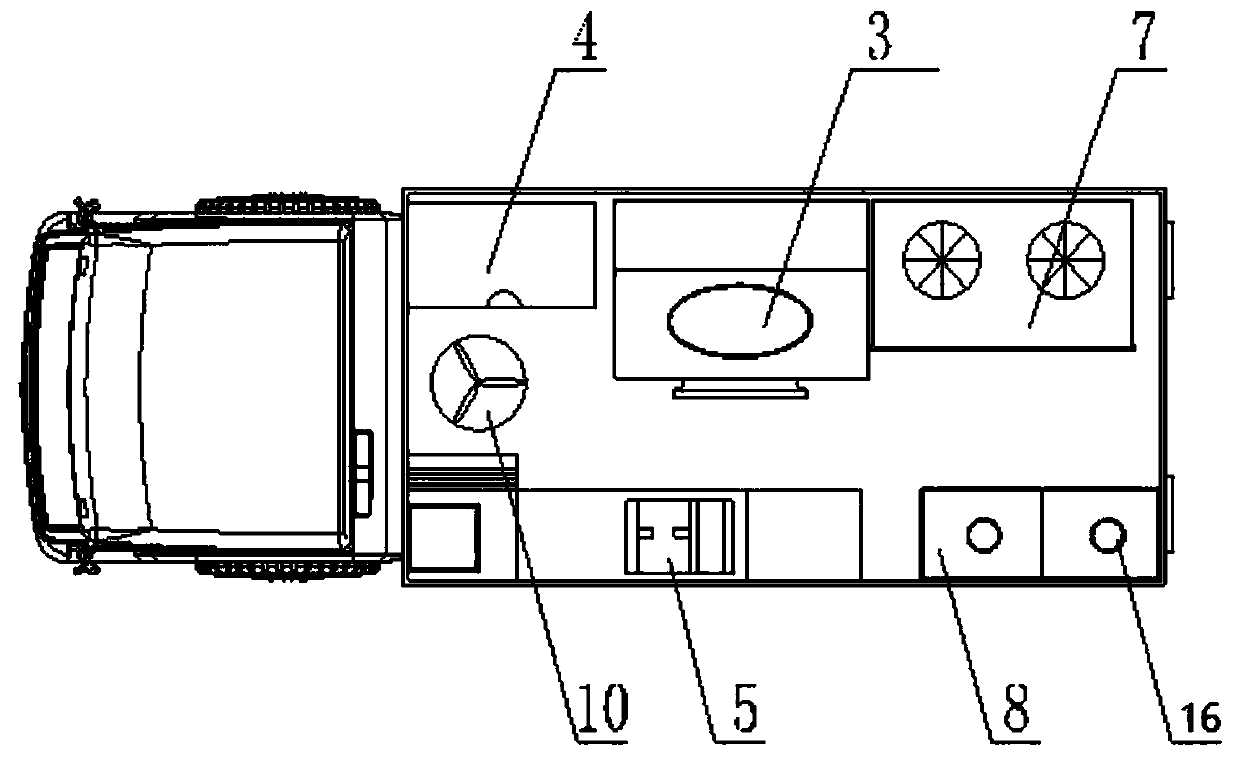

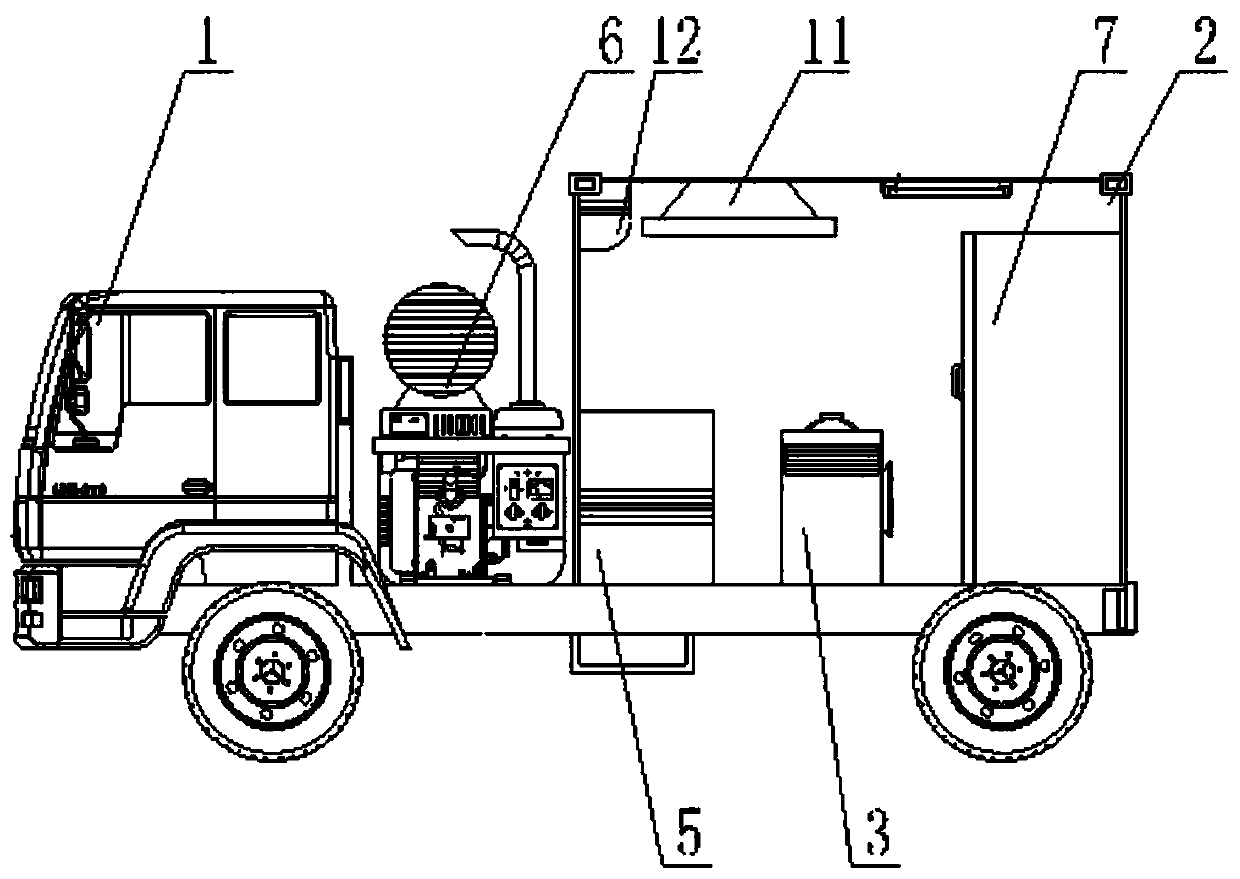

[0051] Such as figure 1 with figure 2 As shown, an automatic semi-finished fast food processing vehicle includes a chassis 1, a compartment 2, two sets of intelligent cooking equipment 3, an intelligent steaming cabinet 4, packaging equipment 5, a power generation system, a refrigerator 7, a water supply system 8, an oil supply system 16, Fan 10, range hood 11, air conditioner 12 and disinfection and sterilization device 9.

[0052] Chassis 1 is used as the carrying platform of the processing vehicle.

[0053] The carriage 2 is arranged above the chassis 1 .

[0054] There is a set of fuel steam generator in the compartment 2 to provide steam for the smart steamer 4. The smart steamer 4 is used for making staple food and is installed on the side of the compartment 2. The fuel steam generator and the smart steamer 4 are used in combination. It can steam rice, steamed buns, steamed vegetables, fast food heating and tableware disinfection.

[0055] The fuel oil steam generat...

Embodiment 2

[0097] An automatic semi-finished fast food processing car, the difference from Embodiment 1 is that the compartment 2 is divided into a front part, a middle part and a rear part.

[0098] Two sets of intelligent cooking equipment 3 are located at the front part of the compartment 2 where the packaging equipment 5 is located.

[0099] Intelligent steaming cabinet 4 is positioned at the middle part of compartment 2, and intelligent steaming cabinet 4 is used for rice, steamed bun staple food processing or carries out fast food heating, steamed dish and tableware disinfection.

[0100] The packaging device 5 is located opposite the intelligent steam cabinet 4, and the packaging device 5 is located at the front and middle of the compartment 2; the packaging device 5 is used for automatic packaging of processed meals.

[0101] Refrigerator 7 is positioned at the rear portion of compartment 2, and refrigerated cabinet 7 is used for the fresh-keeping and storage of food material.

...

Embodiment 3

[0107] An automatic semi-finished fast food processing car, the difference from Embodiment 1 is that the compartment 2 is divided into a front part, a middle part and a rear part.

[0108] Two sets of intelligent cooking equipment 3 are located in the middle of the compartment 2 where the packaging equipment 5 is located.

[0109] Intelligent steaming cabinet 4 is positioned at the front portion of compartment 2, and intelligent steaming cabinet 4 is used for rice, steamed bun staple food processing or carries out fast food heating, steamed dish and tableware disinfection.

[0110] The packaging device 5 is located opposite the intelligent steam cabinet 4, and the packaging device 5 is located at the front and middle of the compartment 2; the packaging device 5 is used for automatic packaging of processed meals.

[0111] Refrigerator 7 is positioned at the rear portion of compartment 2, and refrigerated cabinet 7 is used for the fresh-keeping and storage of food material.

[...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com