Material turnover device and material turnover method

A technology of turning devices and materials, which is applied to conveyor objects, transportation and packaging, motor vehicles, etc., can solve the problems that the turning arm cannot be turned over accurately, increase the overall total amount of AGV, and shorten the battery life of AGV, so as to improve the space utilization rate. , reduce the load, avoid the effect of increasing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

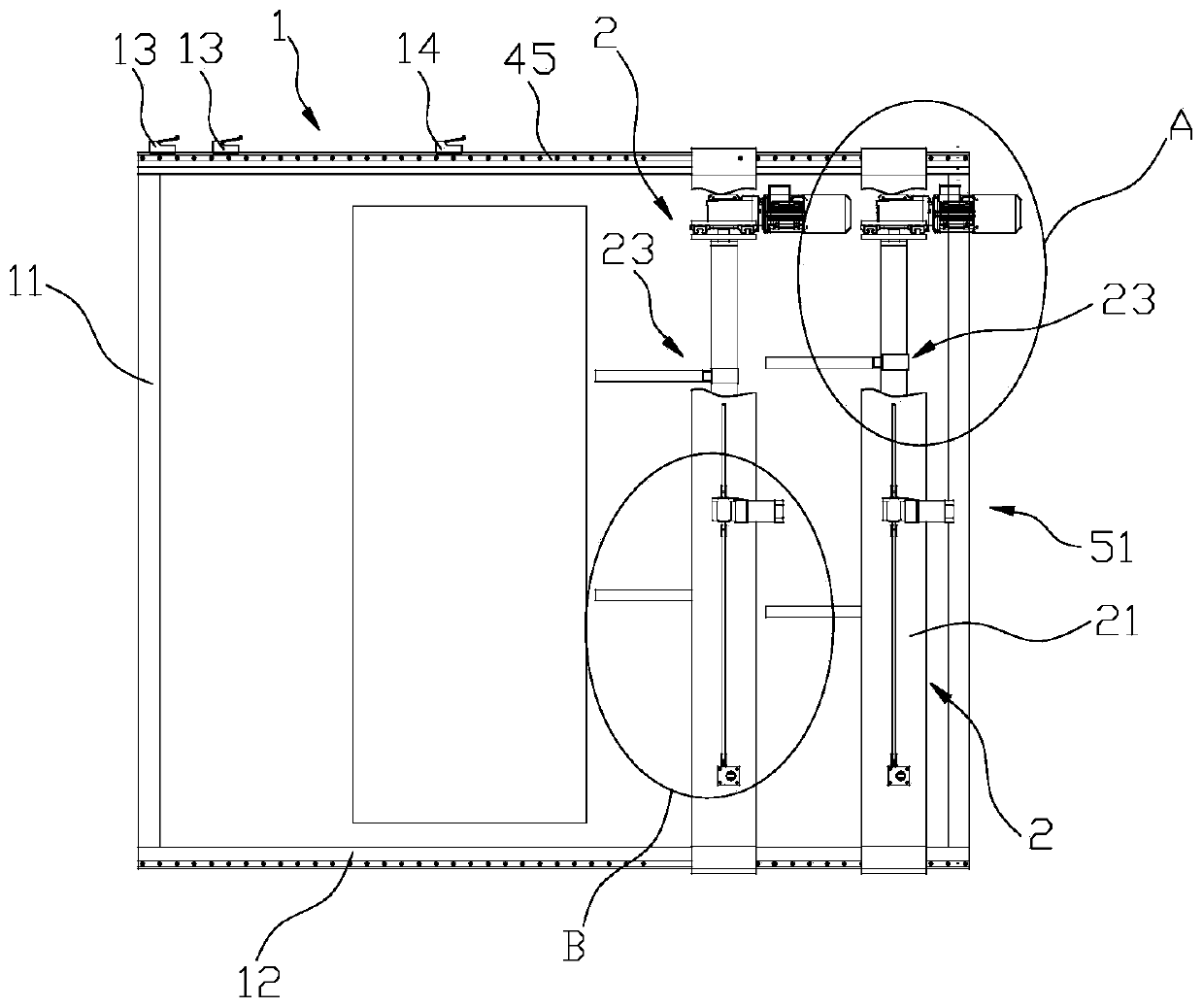

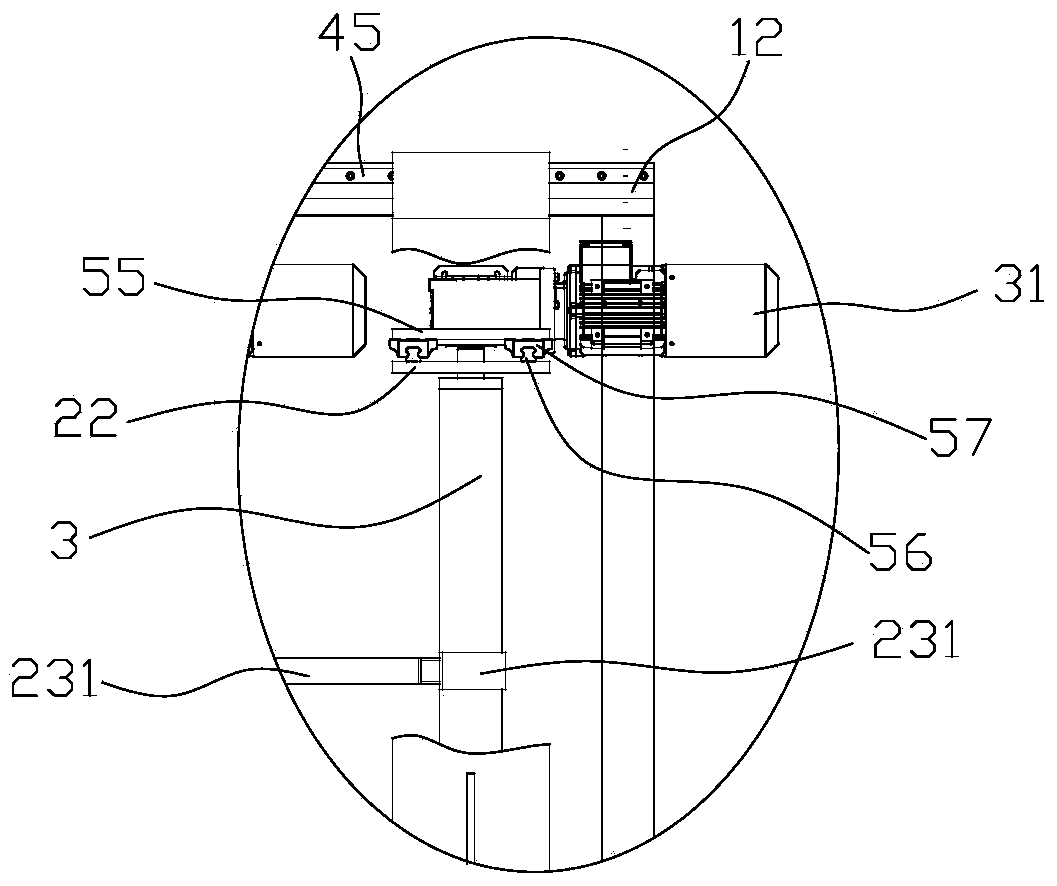

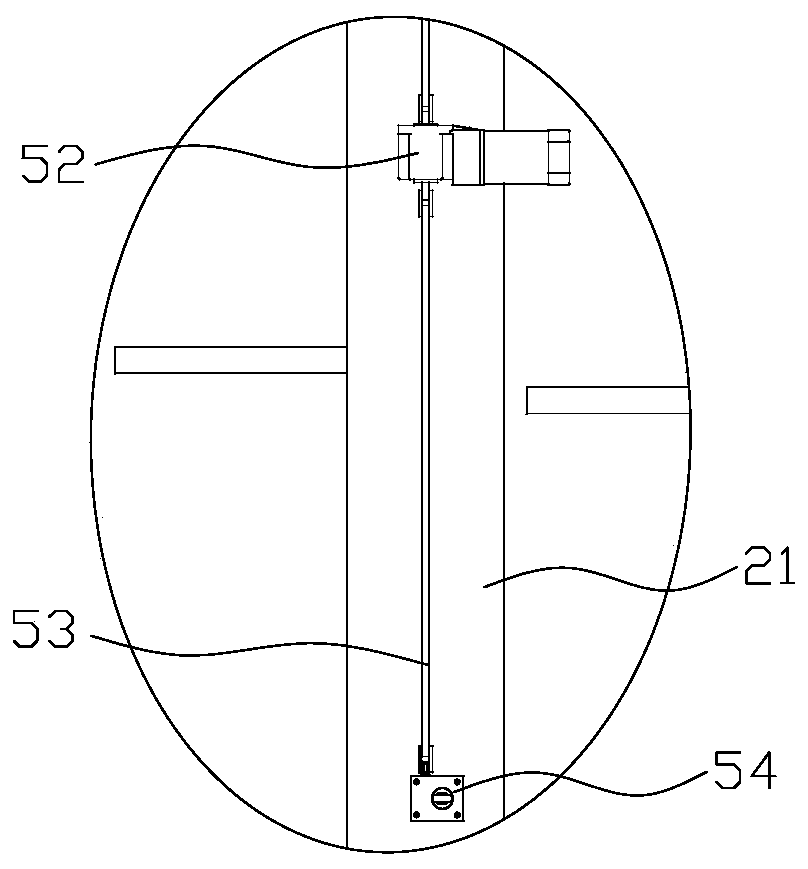

[0058] see Figure 1 to Figure 7 , The material turnover device 1 of this embodiment includes a support 11 and two turning mechanisms 2; the support 11 is provided with a support arm 12 arranged horizontally relative to the ground, and the space under the support arm 12 forms a working area 17; two The turning mechanism 2 is arranged side by side on the support arm 12. The turning mechanism 2 includes a fixed column 21, two connecting arms 22, a clamp 23, a rotating shaft 3 and a turning drive device. The fixed column 21 is horizontally movable and arranged on the On the support arm 12; the two connecting arms 22 are located in the working area 17, and the two connecting arms 22 are arranged oppositely on the front and rear sides of the fixed column 21, and the two ends of the rotating shaft 3 can be axially rotated. At the bottom of the two connecting arms 22, the clamp 23 is arranged on the rotating shaft 3, the clamp 23 is used to clamp the material, and the turning drive d...

Embodiment 2

[0094] see Figure 8 to Figure 17 , the present invention also provides a material turning method using the above-mentioned material turning device 1, comprising the following steps:

[0095] (1) The AGV 6 loaded with material 7 enters the working area 17, and one of the turning mechanisms 2 moves to the side of the AGV 6. The clamp 23 of the turning mechanism 2 clamps the material 7 on the AGV 6, and the turning drive device drives the rotating shaft 3 to rotate. so that the clamp 23 is flipped over;

[0096] (2) The two overturning mechanisms 2 move relative to each other, so that the overturning mechanism 2 holding the material 7 is in an upper position relative to the unloaded overturning mechanism 2;

[0097] (3) The turning mechanism 2 holding the material 7 moves so that the material 7 is transferred to the unloaded turning mechanism 2, or the unloaded turning mechanism 2 moves to clamp the material 7 on another turning mechanism 2 ;

[0098] (4) The turning drive de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com