An automatic flanging equipment for reinforced plate production

A reinforcement plate and automatic turning technology, which is applied in the direction of lifting devices, workbenches, manufacturing tools, etc., can solve the problems of manual labor, shaking or stretching, and heavy weight of the reinforcement plate, so as to realize automation, improve work efficiency, and reduce manual work. The effect of the operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

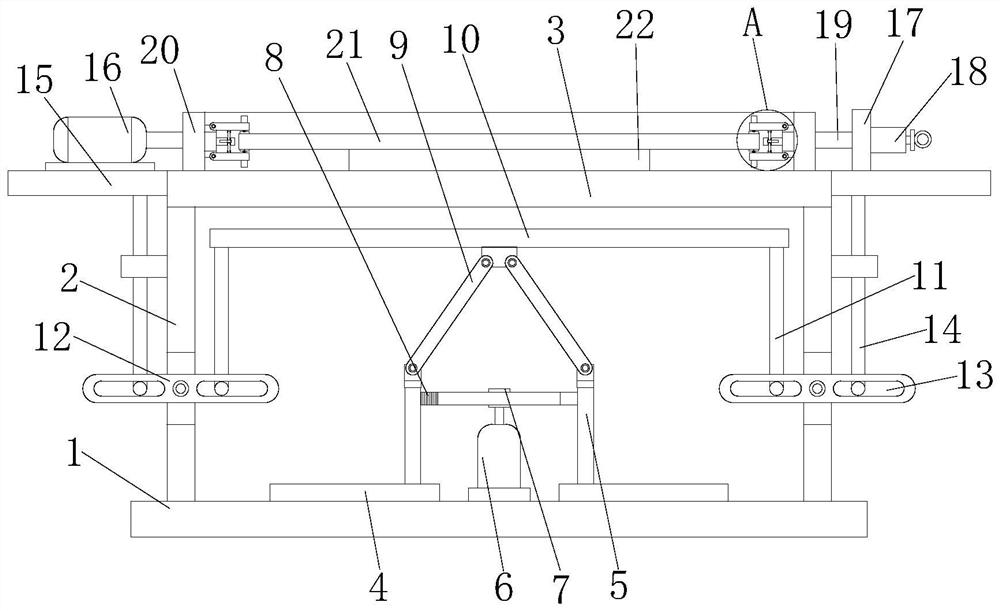

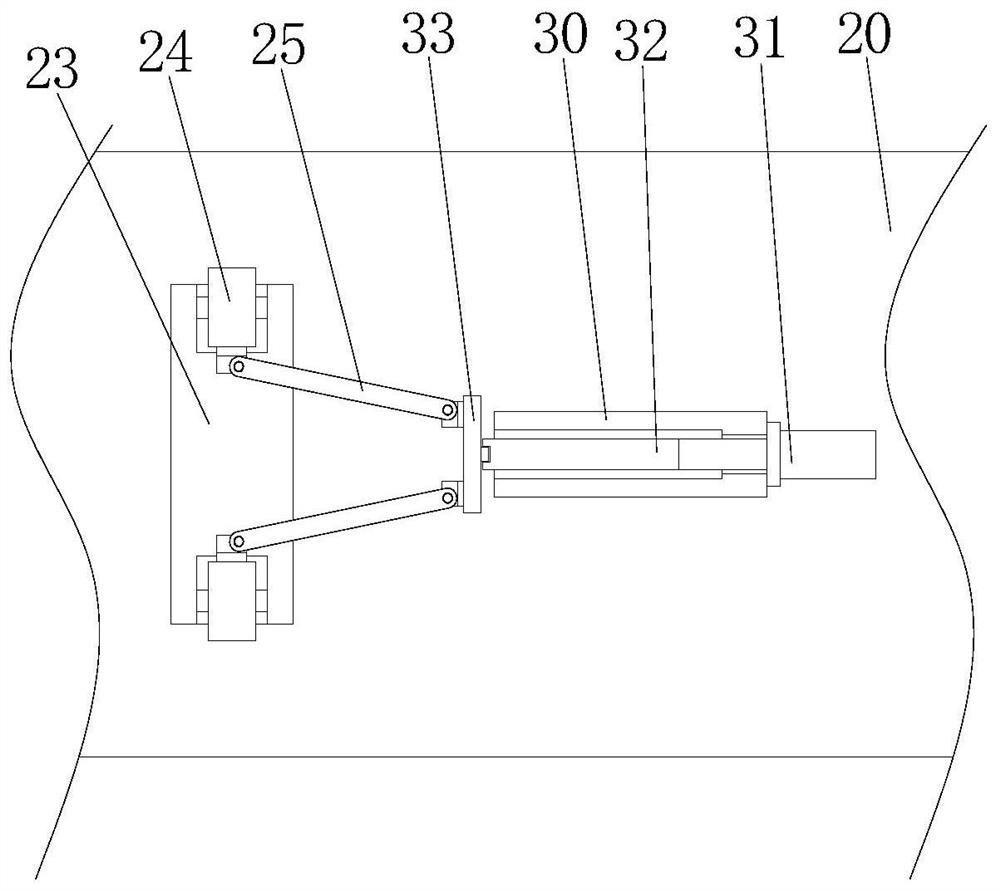

[0028] refer to Figure 1-5 , this embodiment proposes an automatic flanging equipment for the production of reinforced plates, including a base 1, two support columns 2 are symmetrically and fixedly installed on the top of the base 1, and the top of the two support columns 2 is fixedly installed with the same processing Table 3, the top of the base 1 is symmetrically slidably connected with a moving plate 5 between the two supporting columns 2, the top of the base 1 is fixedly installed with a driving motor 6 between the two moving plates 5, and the output shaft of the driving motor 6 A gear 7 is fixedly installed on the top, and a rack 8 is fixedly installed on the side where the two moving plates 5 are close to each other. Rod 9, the tops of the two rotating rods 9 are rotatably connected with the same lifting plate 10, the supporting column 2 is rotatably connected with a linkage rod 12, and one side of the supporting column 2 is slidably connected with a second L-shaped b...

Embodiment 2

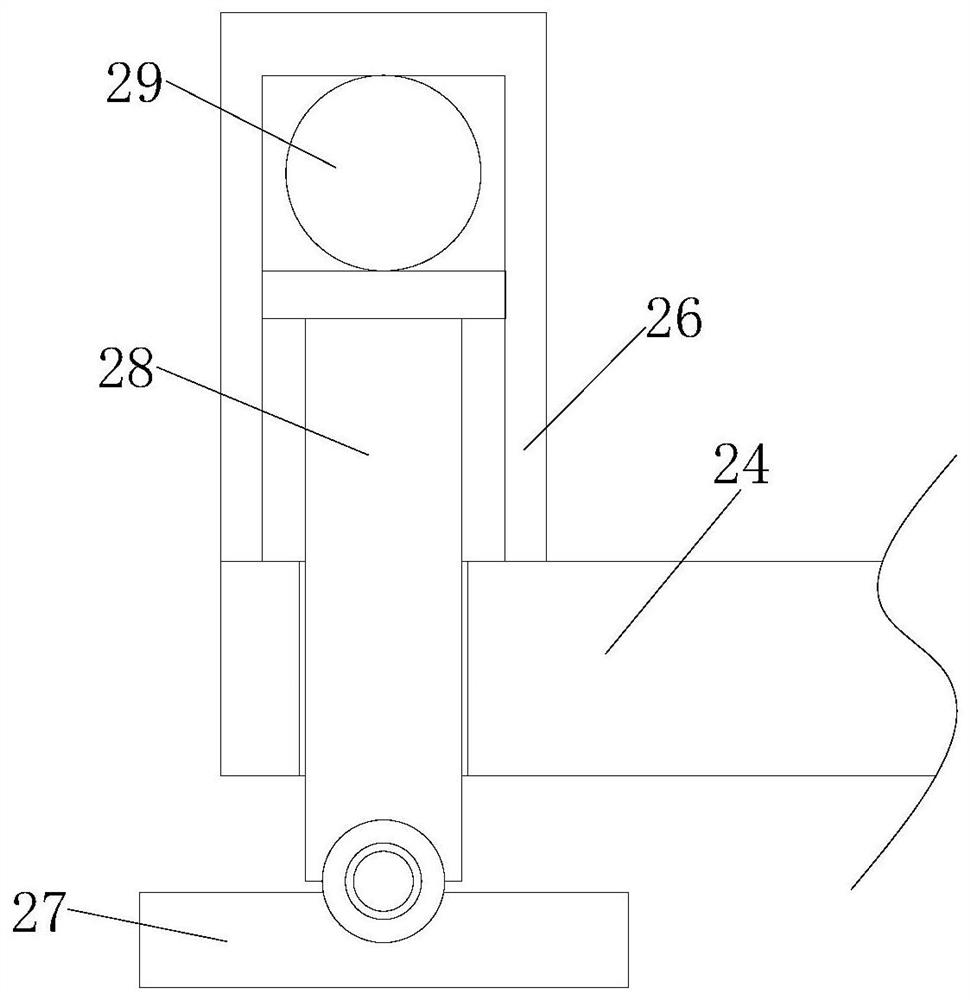

[0032] In this embodiment, a mounting hole is opened on the vertical plate 17, and a bearing 39 is fixedly installed in the mounting hole. The connecting column 19 penetrates the bearing 39 and is fixedly connected with the inner ring of the bearing 39. Rotary connection of column 19.

[0033] In this embodiment, the other end of the connecting column 19 is fixedly mounted with a card seat 34, and a push rod 35 is slidably connected to the inner wall of one side of the limit cover 18, and one end of the push rod 35 is movably clamped with the card seat 34, which can be conveniently aligned. The connecting column 19 is limited.

[0034] In this embodiment, a rectangular groove 40 is opened on one side of the card holder 34, and one end of the push rod 35 extends into the rectangular groove 40 and a rectangular plate 37 is fixedly installed thereon. The cooperation between the plate 37 and the rectangular slot 40 can simplify the clamping step.

[0035] In this embodiment, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com