Gasoline engine tail gas catalytic purifying system conforming to China VI emission standard

An emission standard and catalytic purification technology, which is applied in the direction of exhaust treatment, exhaust equipment, and electronic control of exhaust treatment equipment, etc., can solve the problems of assembly and distribution design influence, inconvenient volume, vehicle layout and installation, etc., to achieve improved purification effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention is described in detail below in conjunction with accompanying drawing:

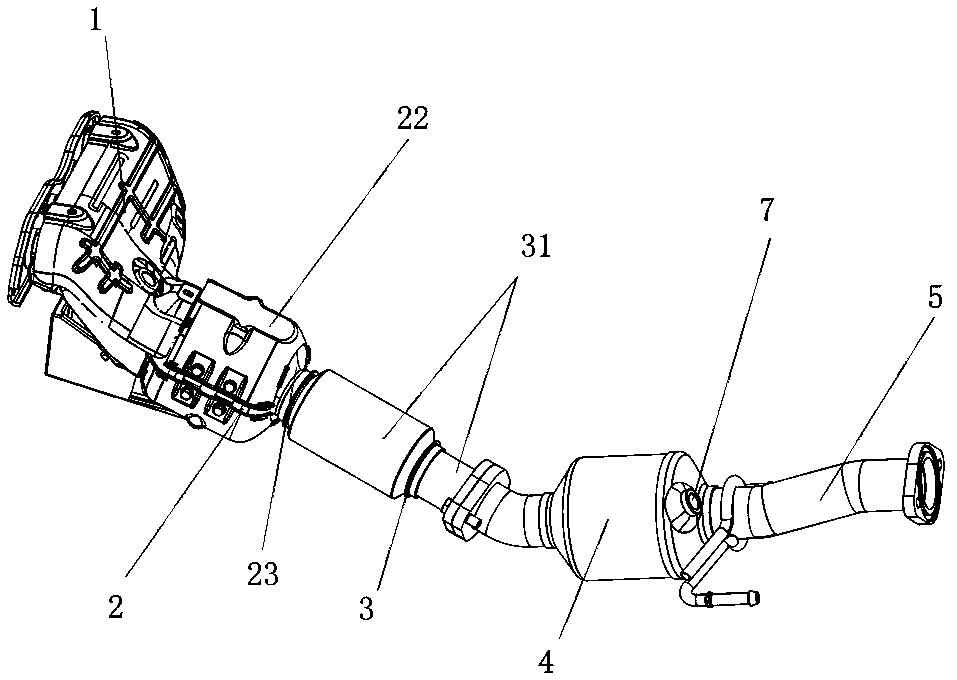

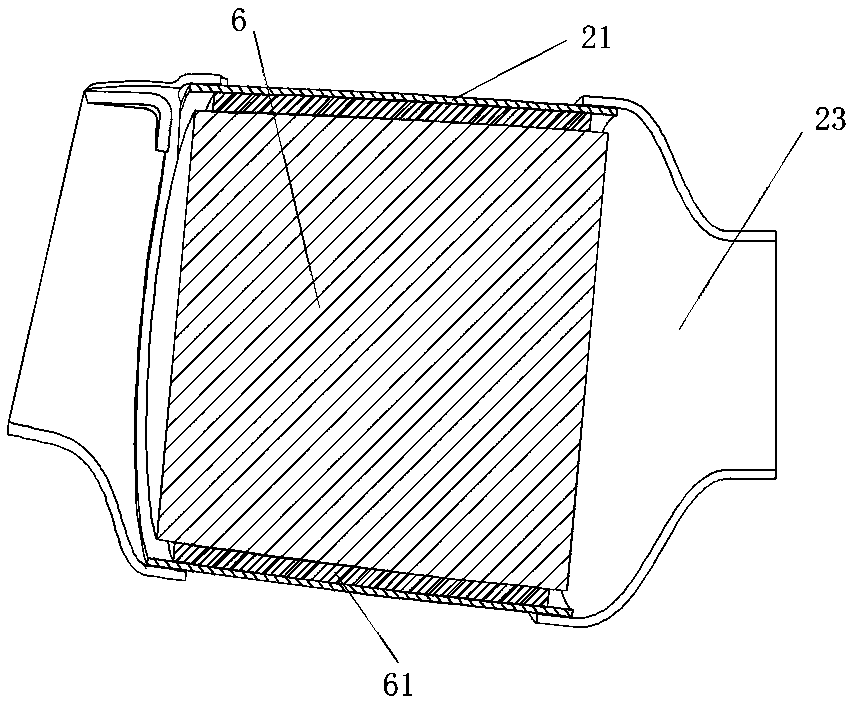

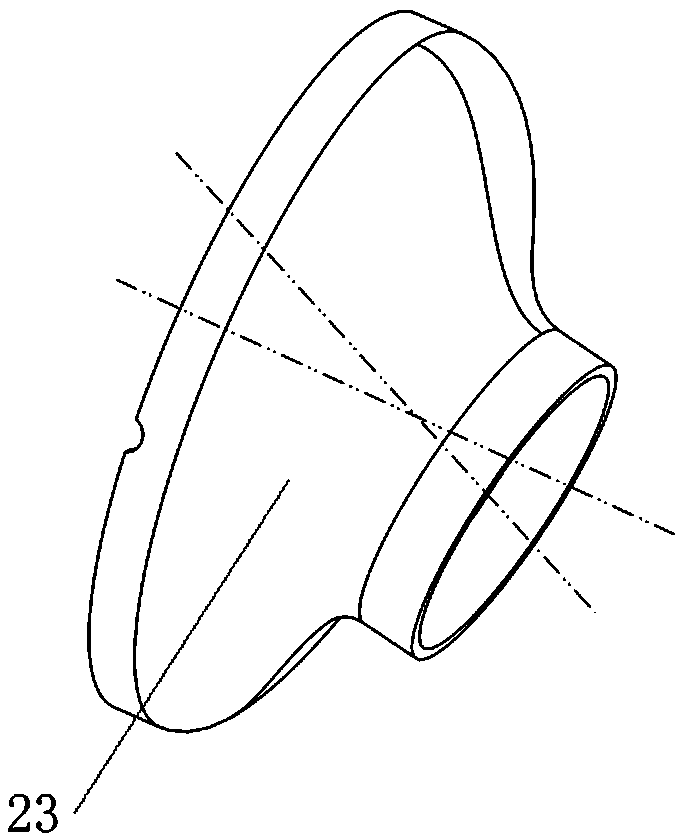

[0025] Such as figure 1 , 2 , 3 and 4 show a gasoline engine tail gas catalytic purification system that meets the National VI emission standards, including an exhaust assembly 1, a pre-catalyst 2, a first connecting pipeline 3, The main catalyst 4 and the second connecting pipeline 5, the pre-catalyst 2 and the main catalyst 4 are respectively embedded with catalytic carriers 6 . The second connecting line 5 is connected downstream to a muffler in the rear exhaust system. Exhaust assembly 1 is composed of the exhaust manifold on the exhaust side of the vehicle engine, which is welded at the edge of the upper and lower components to form a pipe connecting the corresponding number of cylinders of the gasoline engine (a 4-cylinder engine corresponds to 4 exhaust pipes, so that By analogy), the exhaust manifold is sealed and connected with the exhaust side of the engine throug...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com