Sample mounting device and method for lead-bismuth alloy melt corrosion test

A lead-bismuth alloy and corrosion test technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., to achieve the effect of reducing the minimum thickness, reducing the exposed area of the sample, and improving the ability of the immersion test

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

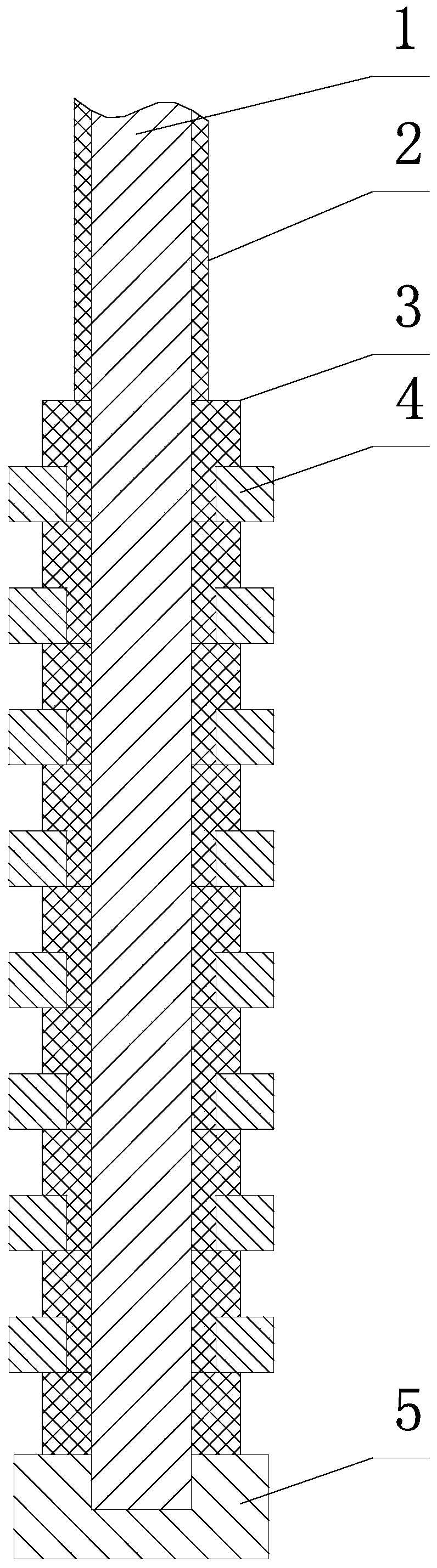

[0038] Such as figure 1 As shown, a sample installation device for lead-bismuth alloy melt corrosion test, the installation device includes a mounting column 1 for installing the sample 4, and also includes a mounting column 1 for realizing the sample 4 on the axis of the mounting column 1 Position restraint restraints;

[0039] The constraint device includes a plurality of isolation rings 3, and the isolation rings 3 can be sleeved on the installation column 1;

[0040] The constraint device also includes a sleeve 2 that can be sleeved on the installation column 1;

[0041] The constraint device further includes a first constraint body arranged at the bottom of the installation column 1 , and the side of the first constraint body protrudes outward relative to the side wall of the installation column 1 .

[0042] The characteristics of the traditional lead-bismuth corrosion test method are as follows: the ceramic crucible is small in volume, and it satisfies a higher surface...

Embodiment 2

[0049] Such as figure 1 As shown, the present embodiment is further limited on the basis of embodiment 1:

[0050] The shape of the spacer ring 3 is a stepped shaft with a diameter at one end greater than that of the other end. The spacer ring 3 is also provided with a journal whose length is greater than the thickness of the sample 4 . With this scheme, in specific applications, the sleeve 2 is set to be less than or equal to the length of the journal, and for each sample 4, one end of the sample 4 is constrained by the shaft shoulder, and the sample is constrained by the big end of another spacer ring 3 The other end of 4, through the formation of annular surface contact or annular line contact, in the radial direction of the installation column 1, the anti-lead-bismuth alloy melt infiltration seal of the mating surface between the sample 4 and the spacer ring 3 is realized; at the same time, this According to the scheme, the constraint stability of the device on the sample...

Embodiment 3

[0056] Such as figure 1 As shown, this embodiment is further limited on the basis of any one of the technical solutions provided by embodiment 1 or 2:

[0057] This embodiment discloses a method for installing sample 4 used in the lead-bismuth alloy melt corrosion test. The installation device described in any one of the above is used to realize the installation of sample 4 on the mounting column 1: the sample 4 It is set as a sheet with a central hole, the spacer ring 3, the sample 4, and the casing 2 are all sleeved on the installation column 1, and a sample 4 is clamped between adjacent spacer rings 3, and finally The upper side of the spacer ring 3 above has a sleeve 2 in contact with the upper end of the spacer ring 3;

[0058] The upper end surface of the first constraining body is used to constrain the lowest position of the layer structure formed by the casing 2, spacer ring 3, and sample 4 on the axis of the mounting column 1;

[0059] A second constraining body is ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com