Novel method for correcting OPC model

A correction method and model technology, which is applied in the photoengraving process of the pattern surface, the original for opto-mechanical processing, optics, etc., can solve the problem of increasing the accuracy of the feedback data, the deviation between the data and the actual value, and the time-consuming, etc. problems, to achieve the effect of improving speed and peak yield, improving chip performance and yield, and reducing the number of iterations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The technical solutions in the present invention will be further described below in conjunction with the accompanying drawings and embodiments.

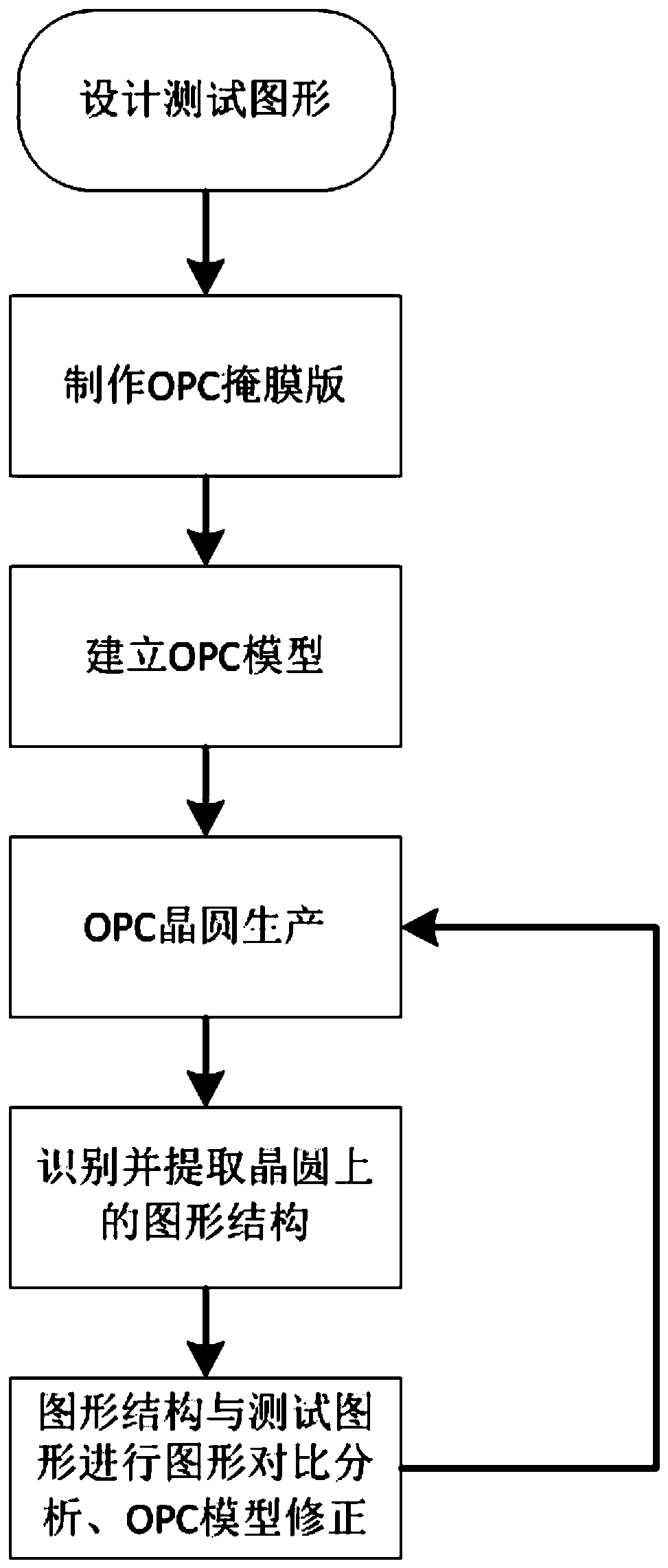

[0022] Such as figure 1 As shown, a calibration method for a new OPC model includes the following steps:

[0023] A correction method for a novel OPC model, comprising the following steps:

[0024] A. Design OPC test pattern;

[0025] B. Make OPC mask plate;

[0026] C. Establish OPC model;

[0027] D. Carry out OPC wafer production to manufacture a physical structure corresponding to the test pattern on the wafer; the physical structure may include electronic devices or semiconductor devices, connecting wires, signs, and the like.

[0028] E, identifying and extracting the graphic structure on the wafer produced in step D;

[0029] F, compare and analyze the graphic structure extracted on the wafer in step E and the test pattern designed in step A, so as to obtain the mismatching or wrong part of the graphic structure on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com