Automobile stabilizer bar multidisciplinary optimization design method based on fatigue and tilting performance

A technology for optimizing design and fatigue performance, applied in the field of multi-disciplinary optimization design of automotive stabilizer bars, it can solve the problems that the design results are difficult to achieve systematic, lack of systematicness and overallity, and increase the design cost, so as to improve the design method and reduce the research and development cycle. Long, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The present invention will be further described below in conjunction with accompanying drawing.

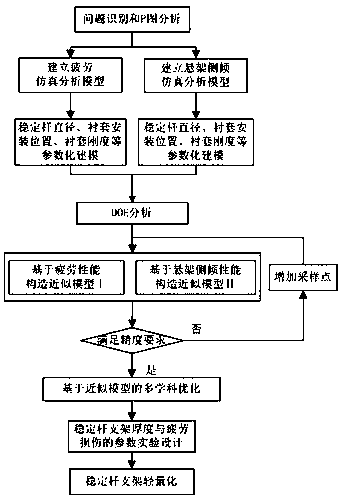

[0030] Such as figure 1 A multidisciplinary optimization design method for automotive stabilizer bars based on fatigue and roll performance is shown, including the following steps:

[0031] Step 1, problem identification and P-diagram analysis, to determine the relevant parameters of the multidisciplinary optimal design of the stabilizer bar;

[0032] There are many factors that affect the fatigue performance of the stabilizer bar and the roll performance of the front suspension, such as: time influence, external ambient temperature, interaction between various systems of the vehicle (suspension system change, tire pressure change), system error (hard point size errors, etc.) and user usage. The present invention mainly starts from the structural design of the stabilizer bar, and determines three input states (input signal, control factor, noise factor) and two output sta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com