Welding process aided design system based on digital twinning and design method thereof

A welding process and auxiliary design technology, applied in design optimization/simulation, CAD numerical modeling, etc., can solve the problems of difficult information sharing, poor real-time performance, and low resource utilization, so as to improve efficiency and quality, realize real-time feedback and The effect of dynamic decision-making

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention can be better understood from the following examples. However, those skilled in the art can easily understand that the content described in the embodiments is only for illustrating the present invention, and should not and will not limit the present invention described in the claims.

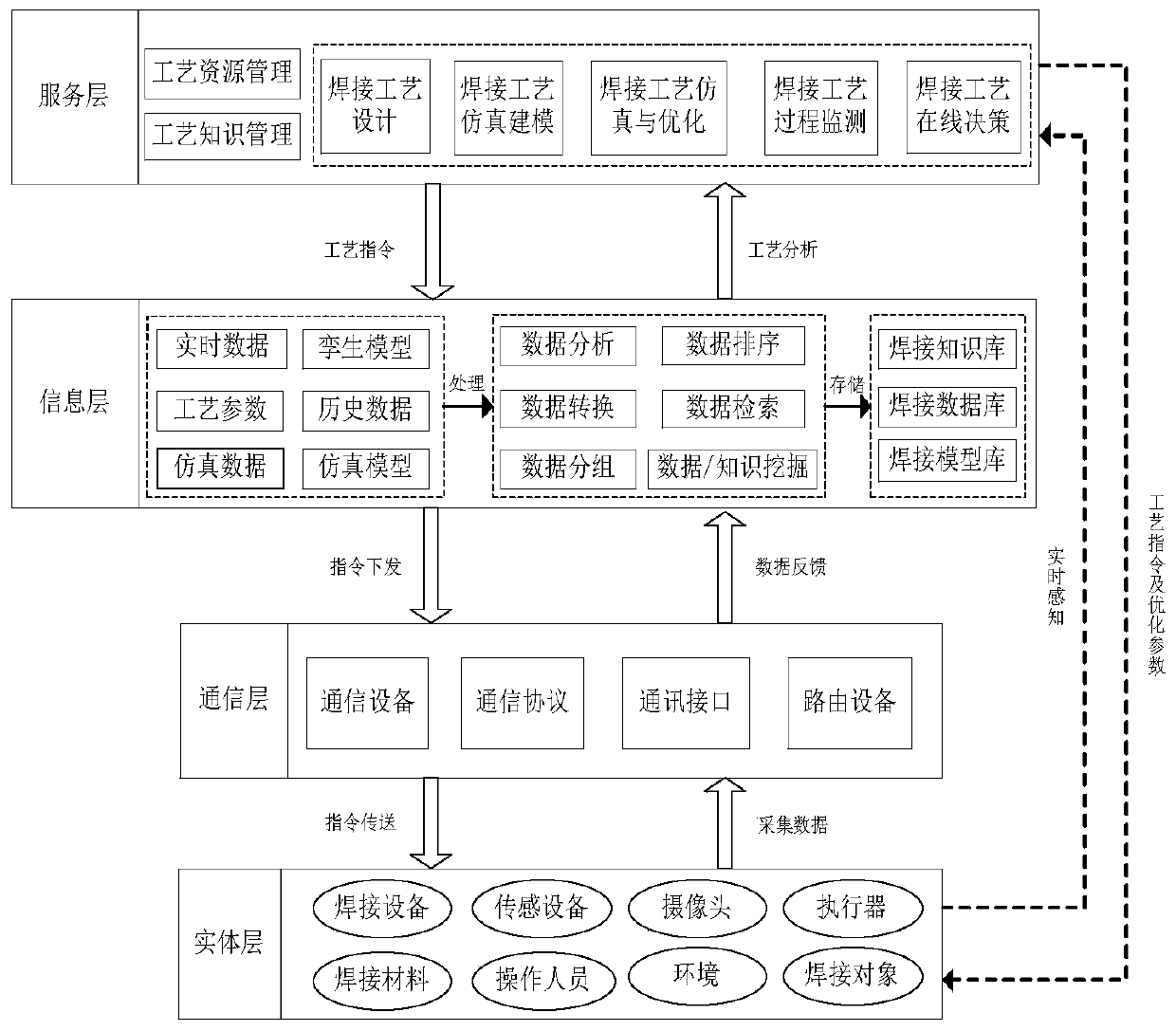

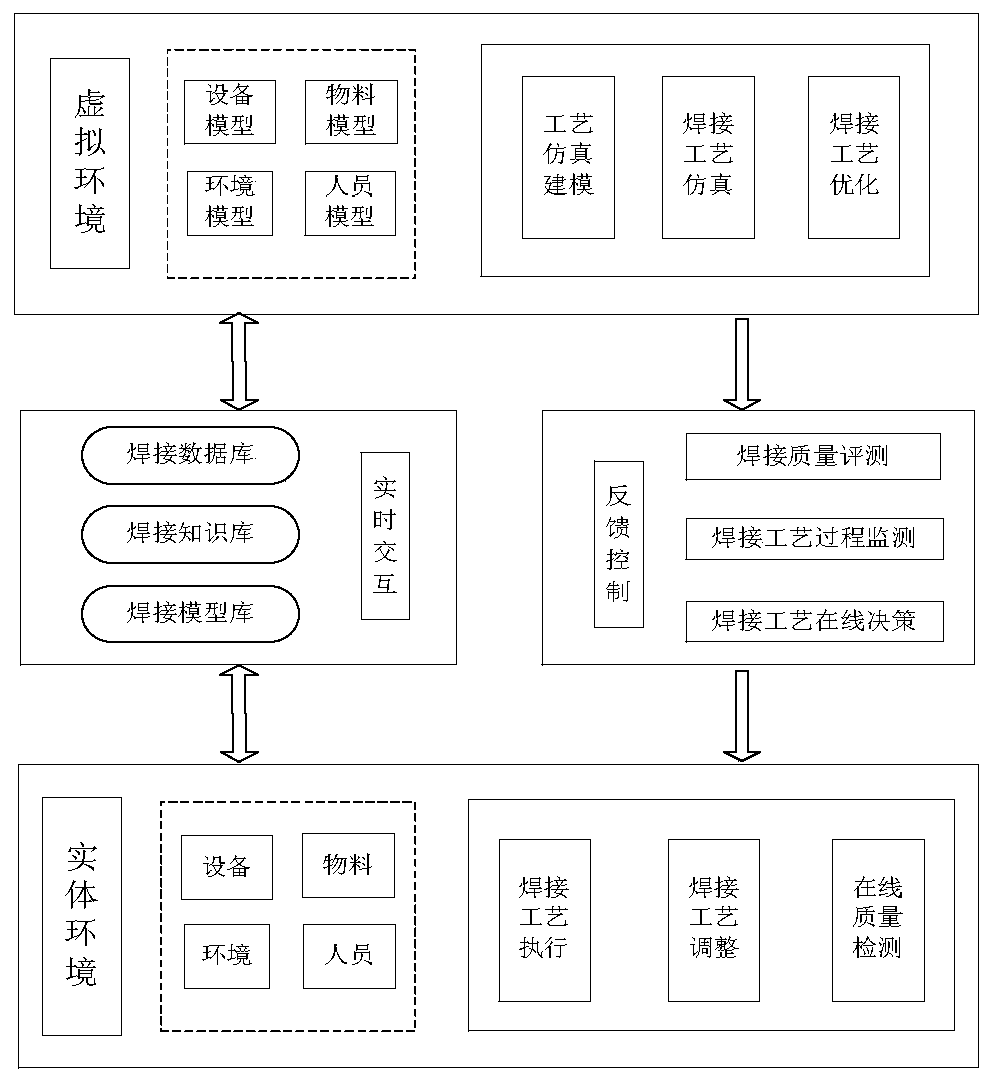

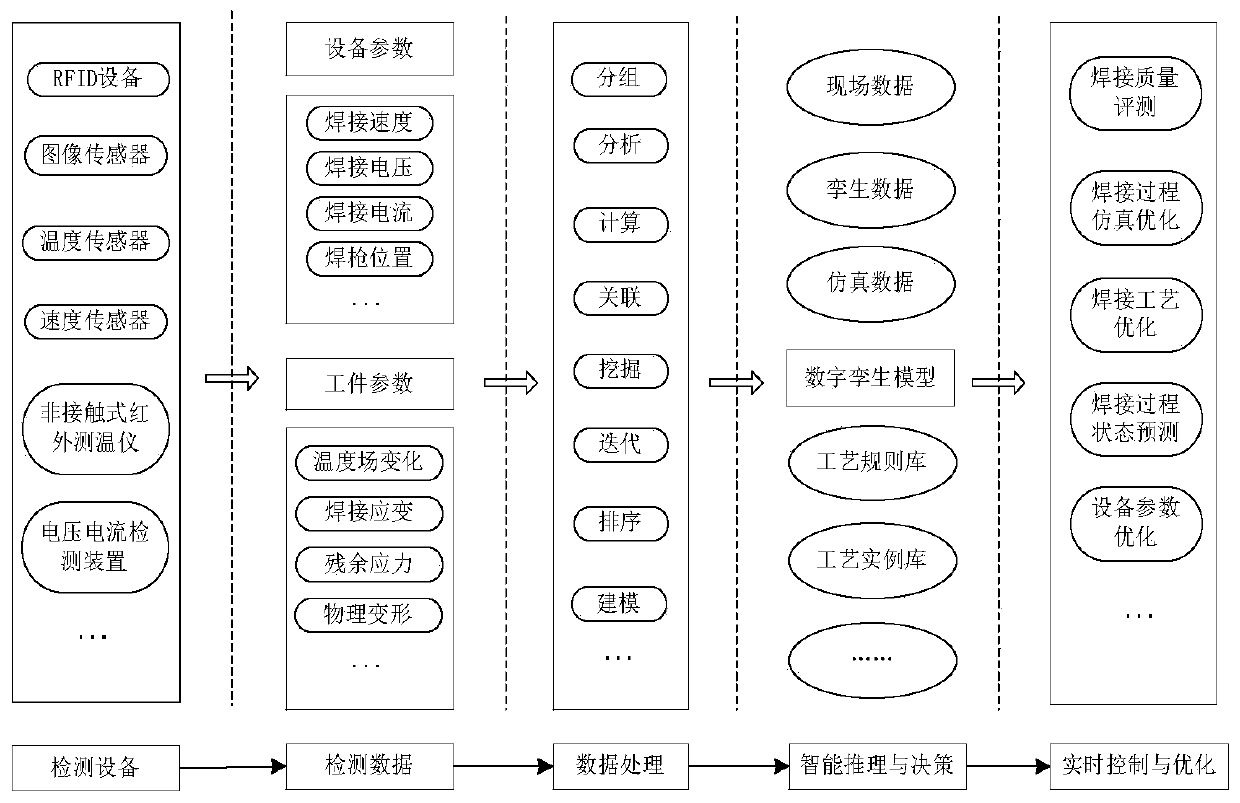

[0025] like Figure 1~3 As shown, the digital twin-based welding process aided design system of the present invention consists of a four-layer structure, including a physical layer, an information layer, a communication layer and a service layer, wherein the physical layer is interconnected with the information layer and the service layer through the communication layer intercommunication.

[0026] Among them, the physical layer refers to the physical entities involved in the actual welding process, including weldments, data acquisition equipment, processing equipment, processing personnel, and final welded product objects. Welding data acquisition equipment includ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com