Method of drilling, positioning and manufacturing ultra-long multilayer board

A production method and multi-layer board technology, which is applied in the fields of printed circuit manufacturing, electrical components, printed circuits, etc., can solve the problems of restricting the development of the industry, unsatisfactory, and large parts, and achieve the effect of improving the matching degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] A method for manufacturing super-long multi-layer board drilling positioning, characterized in that it comprises the following steps:

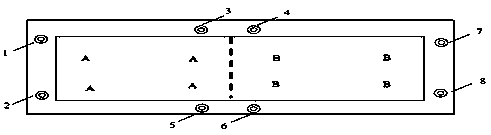

[0027] S1. Inner layer data design, design 1, 2, 3, 4, 5, 6, 7, 8 on the inner layer film, a total of eight positioning target hole graphics;

[0028] S2. After the lamination is completed, drill the corresponding 8 positioning target holes when shooting with X-Ray;

[0029] S3. Drilling data production, the overall drill belt is disassembled into 2 sections of drill belt, namely A section drill belt and B section drill belt, the A section drill belt uses No. Drilling belts are positioned using No. 4, 6, 7, and 8 positioning target holes;

[0030] S4. When drilling, firstly import the drilling tape data of section A to complete the production, and then import the drilling tape data of section B to replace the positioning target hole to complete the production of section B.

[0031] Further, in step S1, the positioning target hole 1 an...

Embodiment 2

[0044] A method for manufacturing super-long multi-layer board drilling positioning, characterized in that it comprises the following steps:

[0045] S1. Inner layer data design, design 1, 2, 3, 4, 5, 6, 7, 8 on the inner layer film, a total of eight positioning target hole graphics;

[0046] S2. After the lamination is completed, drill the corresponding 8 positioning target holes when shooting with X-Ray;

[0047] S3. Drilling data production, the overall drill belt is disassembled into 2 sections of drill belt, namely A section drill belt and B section drill belt, the A section drill belt uses No. Drilling belts are positioned using No. 4, 6, 7, and 8 positioning target holes;

[0048] S4. When drilling, firstly import the drilling tape data of section A to complete the production, and then import the drilling tape data of section B to replace the positioning target hole to complete the production of section B.

[0049] Further, in step S1, the positioning target hole 1 an...

Embodiment 3

[0062] A method for manufacturing super-long multi-layer board drilling positioning, characterized in that it comprises the following steps:

[0063] S1. Inner layer data design, design 1, 2, 3, 4, 5, 6, 7, 8 on the inner layer film, a total of eight positioning target hole graphics;

[0064] S2. After the lamination is completed, drill the corresponding 8 positioning target holes when shooting with X-Ray;

[0065] S3. Drilling data production, the overall drill belt is disassembled into 2 sections of drill belt, namely A section drill belt and B section drill belt, the A section drill belt uses No. Drilling belts are positioned using No. 4, 6, 7, and 8 positioning target holes;

[0066] S4. When drilling, firstly import the drilling tape data of section A to complete the production, and then import the drilling tape data of section B to replace the positioning target hole to complete the production of section B.

[0067] Further, in step S1, the positioning target hole 1 an...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap