Improved MCVD system tail gas powder removal rod

An improved exhaust gas technology, which is applied in the direction of cleaning hollow objects, cleaning methods and utensils, chemical instruments and methods, etc., can solve the problems of huge fluctuations in the diameter of reaction tubes, reduced product consistency, and reduced product quality, and achieve consistent product quality The effect of guaranteeing stability, reducing the fluctuation of reactant airflow, and increasing the swirling area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

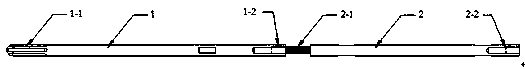

[0022] Taking the tailpipe with a target inner diameter of 30mm and a length of 800mm as an example, we will illustrate by assembling the ash removal rod that matches it. The specific operation method and steps are as follows:

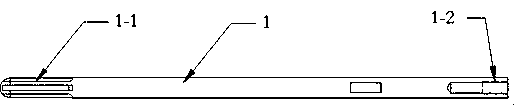

[0023] (1)) Use a vernier caliper to measure the inner diameter of the tail pipe, and select the rod head 1 with a diameter of 12mm; satisfy the relationship between the diameter of the end of the rod head 1 that is in contact with the inner wall of the tail pipe and the diameter of the inner wall of the tail pipe: 2.5d=D. Its material is Hastelloy alloy.

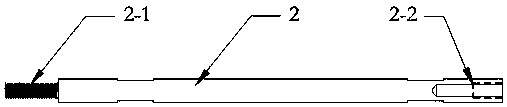

[0024] (2) Measure the front and rear positions of the expander of the MCVD system and combine the length of the tail pipe to determine the length of the ash removal rod to be 1250mm, and then determine the required shaft length according to the installation position of the rod head 1 and the ash removal rod. The shaft 2 is made of polytetrafluoroethylene.

[0025] (3) Process the air guide groove...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com