Wire drawing machine convenient for material changing

A technology of wire drawing machine and wire drawing die, which is applied in the direction of wire drawing die, etc., can solve problems such as time-consuming, limited wire length, and limited work efficiency, so as to increase work efficiency, avoid frequent shutdowns, and ensure stability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

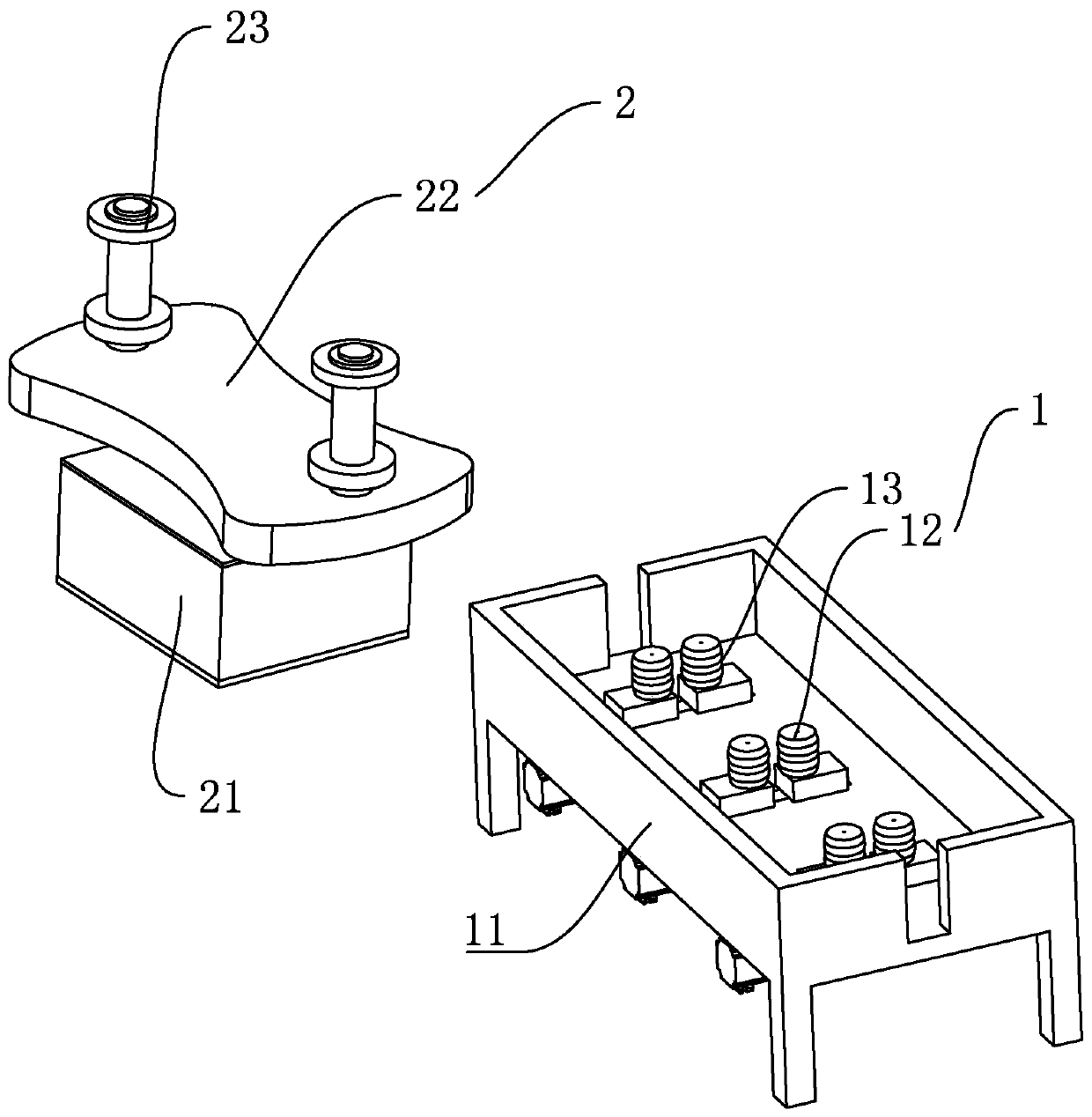

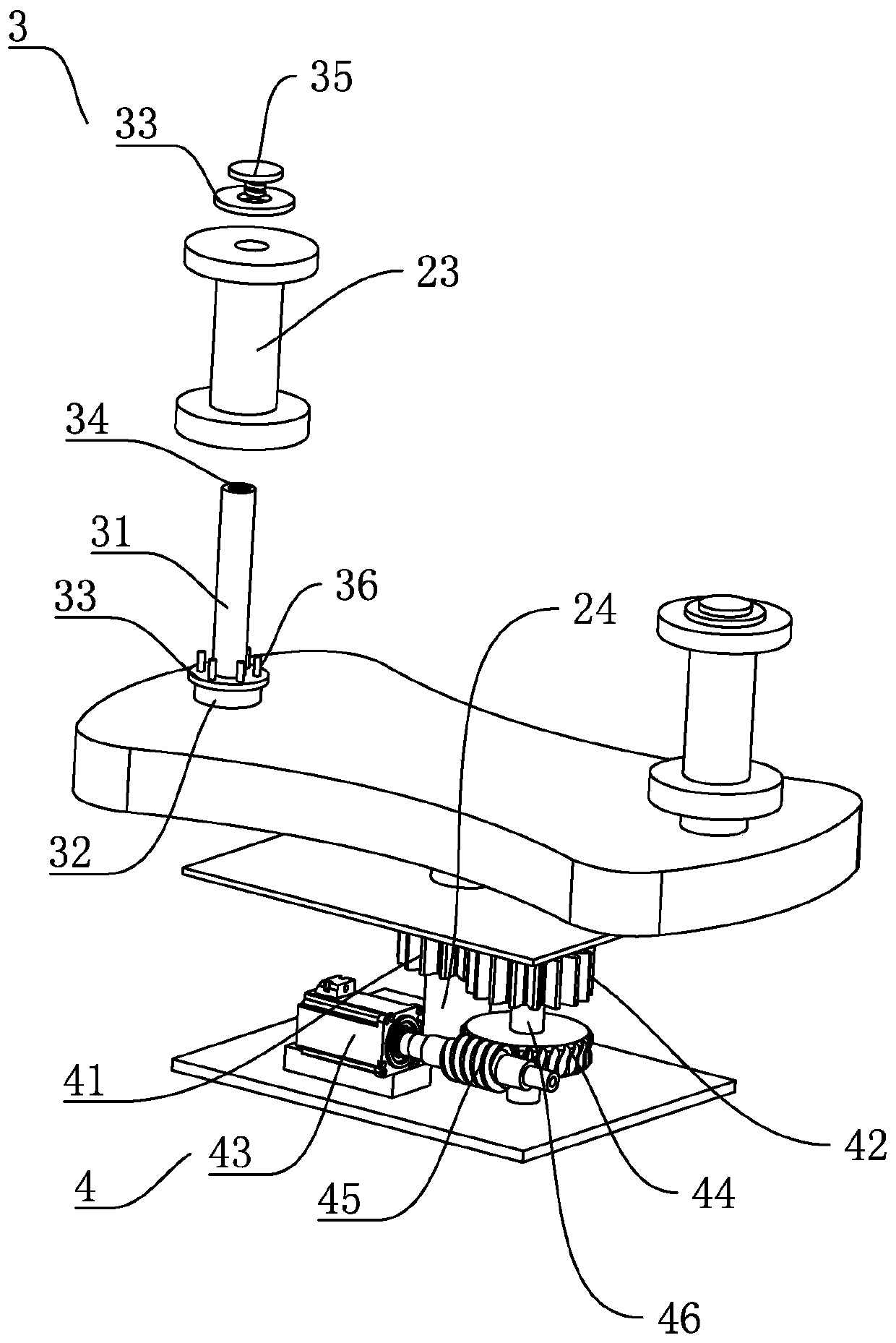

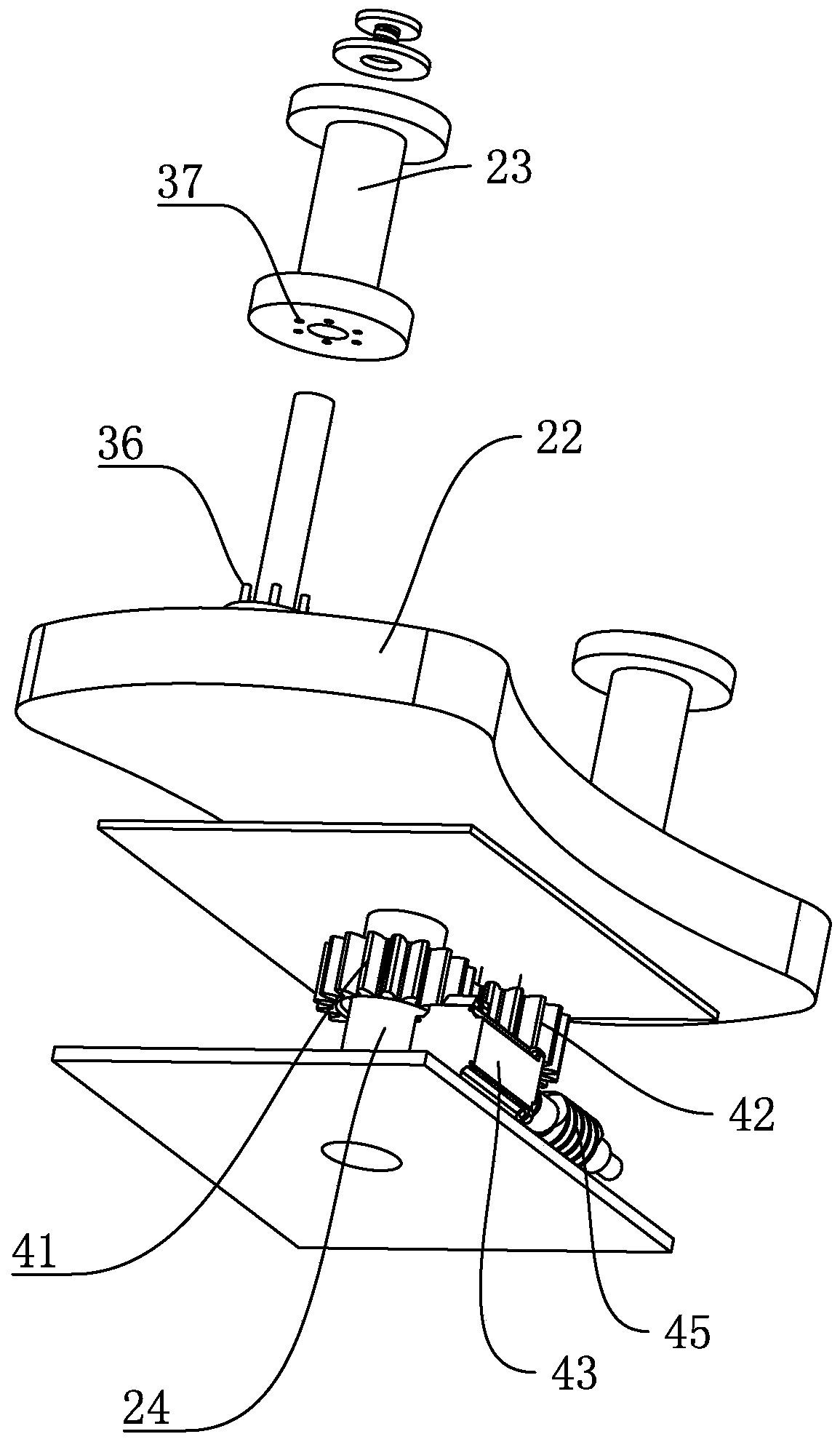

[0026] A wire drawing machine that is convenient for refueling provided in this embodiment has a structure such as Figure 1-3 As shown, a wire drawing machine that is convenient for refueling includes a drafting machine, a wire drawing module 1, a winder 2, and a wire arrangement machine. The winder 2 includes a machine base 21 fixed on the ground, and the top of the machine base 21 is set There is a turntable 22 rotatably connected to the machine base 21. Symmetrically arranged winding rollers 23 are respectively arranged on both sides of the turntable 22. The takeup rollers 23 are detachably connected to the turntable 22 through movable connectors 3. The turntable 22 passes through the The provided rotating shaft 24 is rotationally connected with the machine base 21, and the machine base 21 is provided with a rotating mechanism 4 for driving the rotating shaft 24 and the rotating disk 22 to rotate 180° around its center line.

[0027] Such as Figure 1-3 As shown, the rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com