Method for adjusting vibration in rotating surface of rotor hub of a helicopter

A helicopter rotor and vibration adjustment technology, which is applied to rotorcraft, motor vehicles, aircraft, etc., can solve outstanding problems and achieve high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

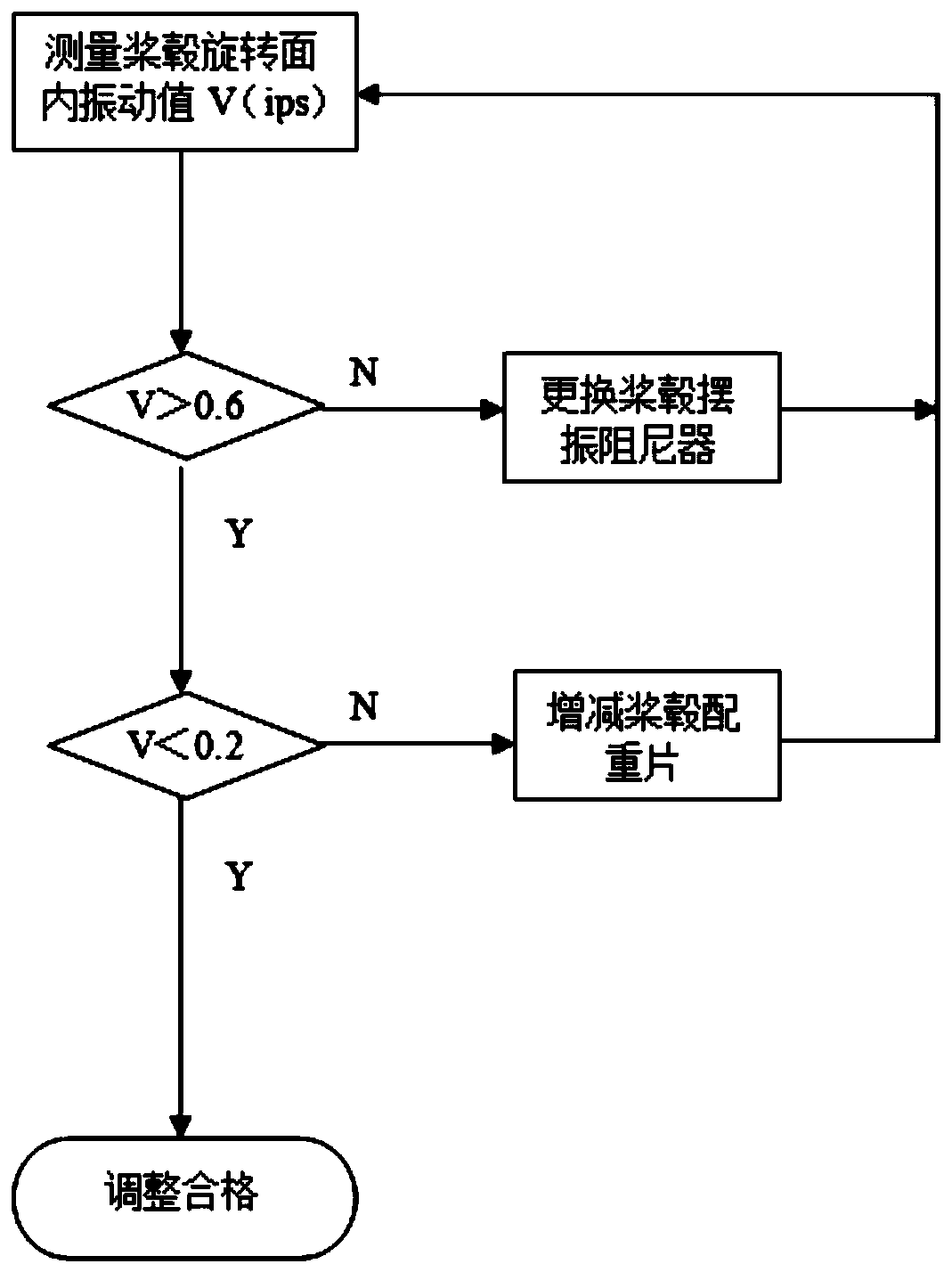

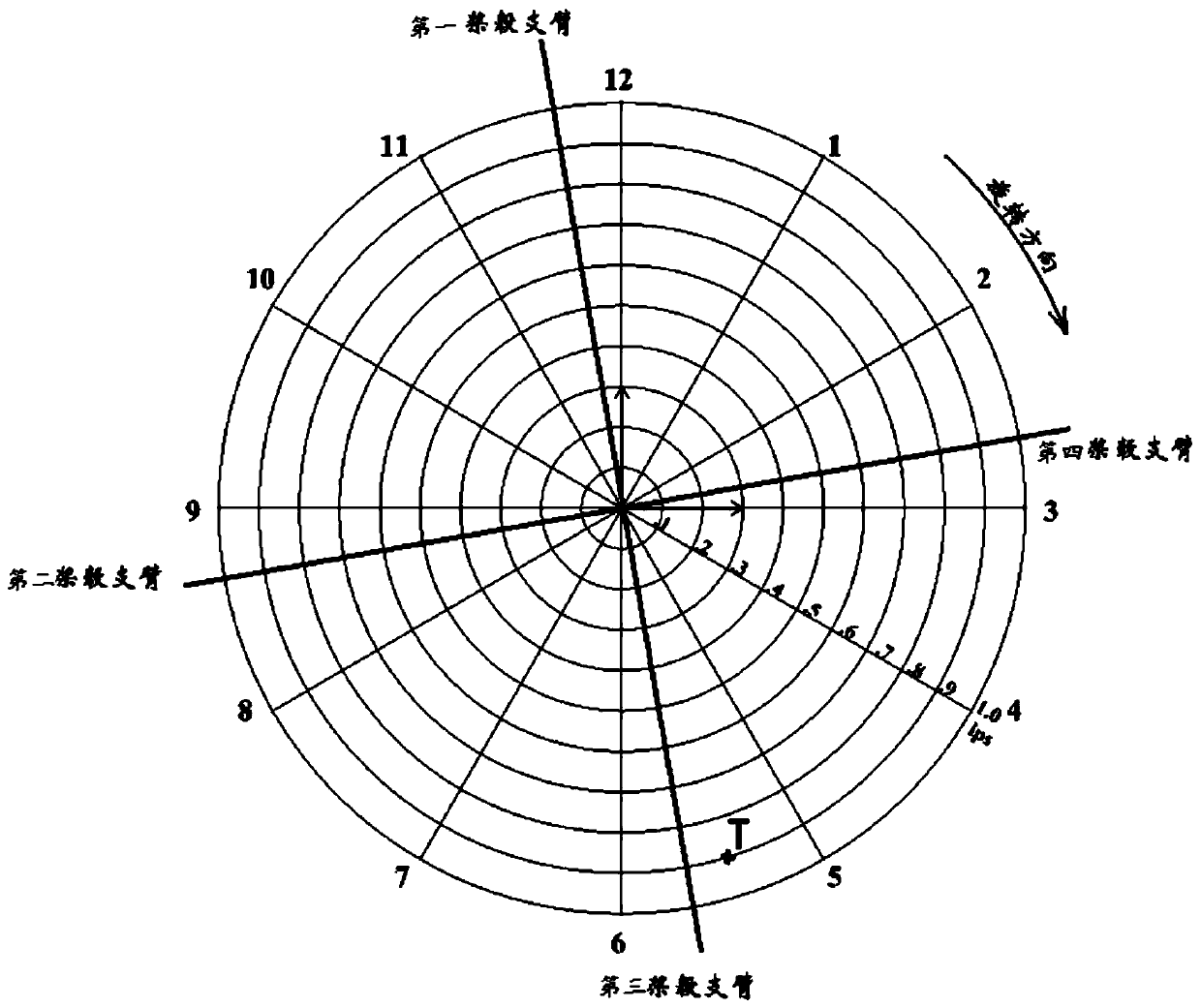

[0031] see figure 2 , taking the specific vibration adjustment method of the rotor hub with four blades as an example:

[0032] After testing, the initial vibration value of the rotor hub is 0.9ips, and the phase is 5:28 (clock notation), which is represented by the "T" point at figure 2 According to the figure, the rotation direction of the rotor of this type of aircraft is clockwise when viewed from above.

[0033] The damper of the propeller arm 4 that lags behind the vibration phase and is closest to the 90° phase difference from the vibration phase can be selected for adjustment; the adjustment method is: the dynamic stiffness increases, and the increase is eccentric force / average damper displacement;

[0034] Or select the damper of propeller arm 2 that is ahead of the vibration phase and has the closest 90° phase difference to the vibration phase for adjustment; the adjustment method is: the dynamic stiffness is reduced, and the reduction is eccentric force / average d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com