Labeling device of pre-gluing label

A pre-glue and labeling technology, which is applied in the direction of labeling, labeling, labeling machines, etc., can solve the problems of high precision of mechanical assembly, malfunction of knives, and low cutting efficiency, so as to achieve long service life, improve cutting efficiency and Cutting accuracy and cutting quality, the effect of easy maintenance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the accompanying drawings and preferred embodiments.

[0022] First introduce the pre-adhesive label 7 to be cut. Such as Figure 4 As shown, the pre-adhesive labels 7 to be cut are connected end to end in rolls, and the patterned side of each pre-adhesive label 7 is the front side, and the other side is the back side. The back of the head and the back of the tail of each pre-glued label 7 are pre-coated with glue. For ease of description, they are referred to as the head glued area 71 and the tail glued area 72. Two adjacent pre-glued labels to be cut A partition 73 for cutting is provided between the labels 7 .

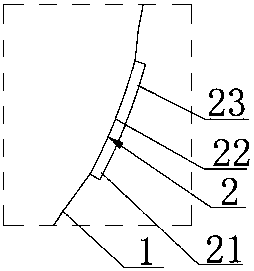

[0023] Such as figure 1 As shown, the labeling device for pre-glued labels includes: a labeling drum 1, the surface of the drum body of the labeling drum 1 is provided with a number of adsorption holes that communicate with the negative pressure mechanism, and at least the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com