Grinding surface roughness detection method based on quaternion singular value entropy index

A technology of surface roughness and detection method, which is applied to measurement devices, instruments, optical devices, etc., can solve the problem of difficult to obtain significant color difference information, and achieve the effect of simplified optical path design, high accuracy, and reduced reflection process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

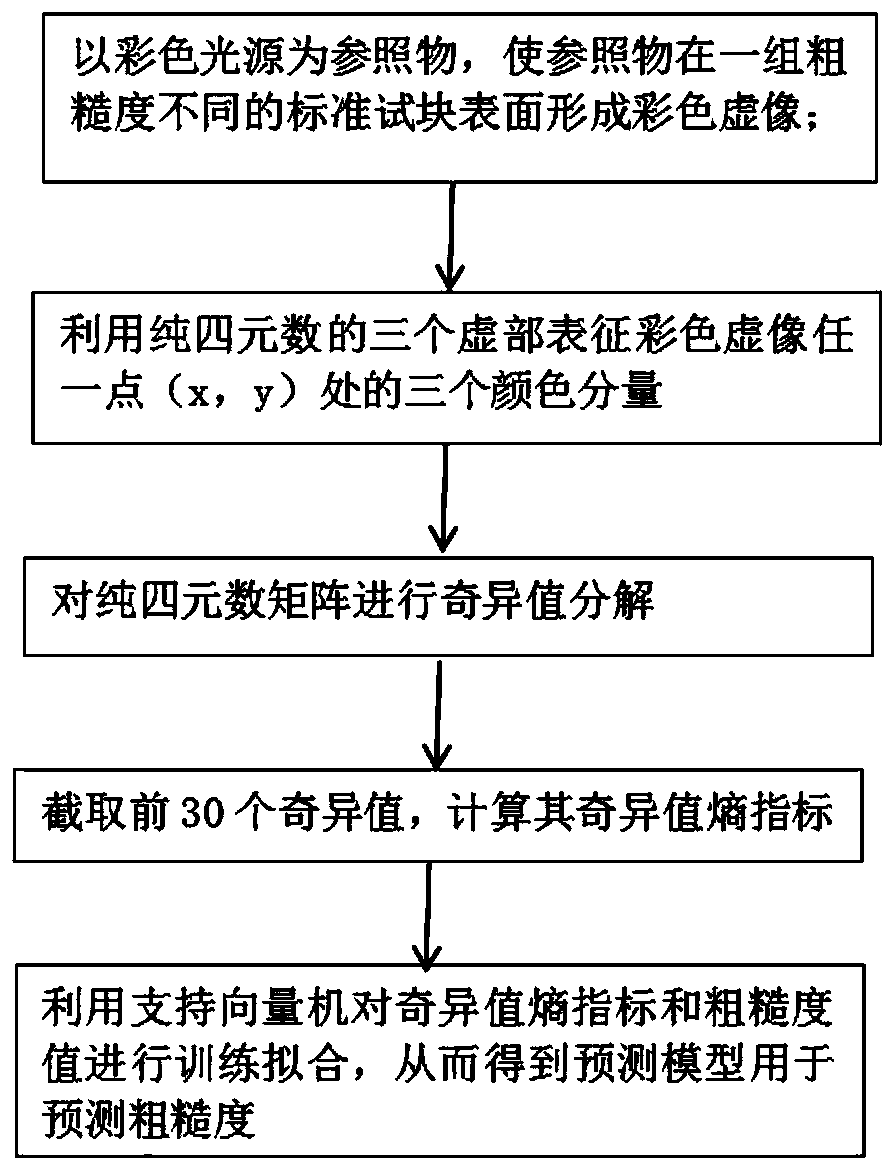

[0036] The object of the present invention is to explore a new indicator based on RGB color space and can express surface roughness objectively, simply and accurately. In order to better illustrate the principle and application of the present invention, firstly introduce the surface roughness evaluation mechanism and the basic mathematical theory applied to the present invention.

[0037] 1. Surface roughness evaluation mechanism

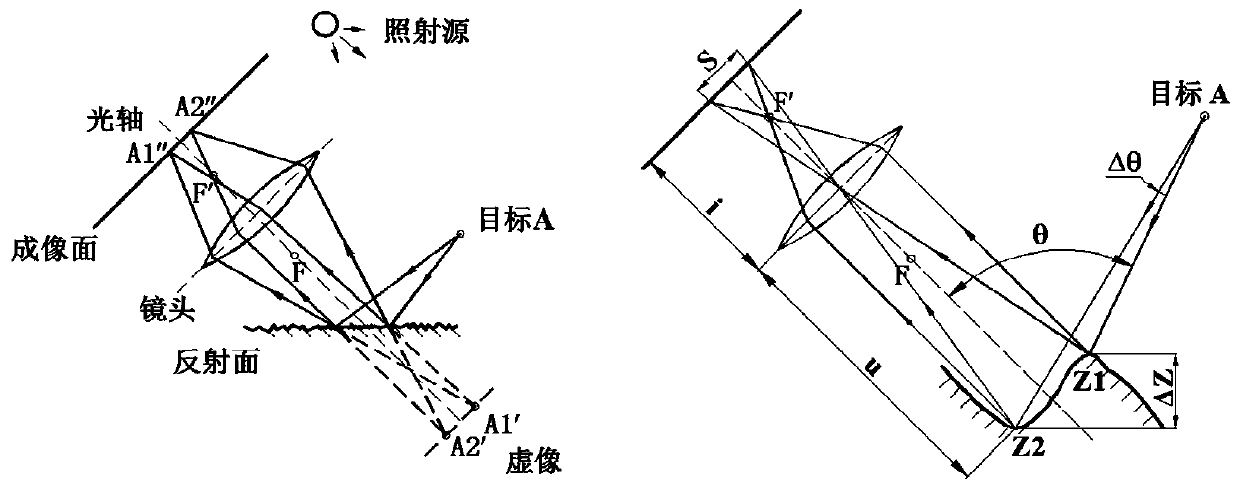

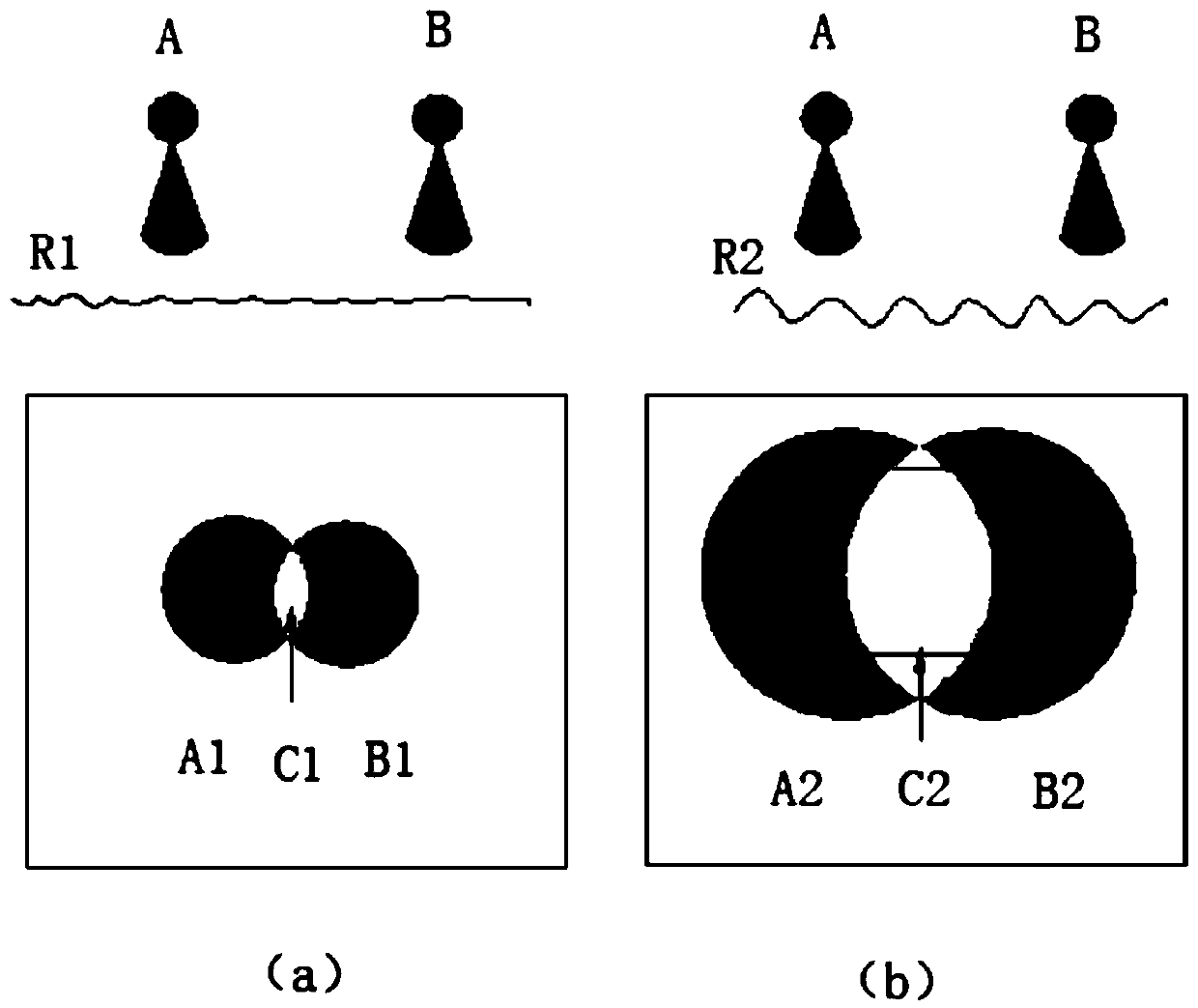

[0038] The imaging principle of rough surface is as follows: figure 1 shown. When the light source shines on the surface of the target A, the target A can be regarded as a point light source. Assuming that only two beams of light are emitted from point A, for the reflective surface of the grinding sample, the light emitted by point A diverges after being reflected by the rough surface, and the same point will produce multiple virtual images with reduced brightness, that is, the situation of one object with multiple images , such as A1, A2, such ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com