Rapid identification method for measuring perpendicularity error of numerical control machine tool based on ball rod instrument

A technology of numerical control machine tools and identification methods, applied in the direction of instruments, program control, computer control, etc., can solve the problems of cumbersome operation process and long detection time, and achieve the effect of improving detection efficiency, simple detection procedure and shortening detection time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0049] attached figure 1 Shown is a schematic structural diagram of a cradle-type five-axis CNC machine tool, and the method of the present invention is described by taking the cradle-type five-axis CNC machine tool as an example.

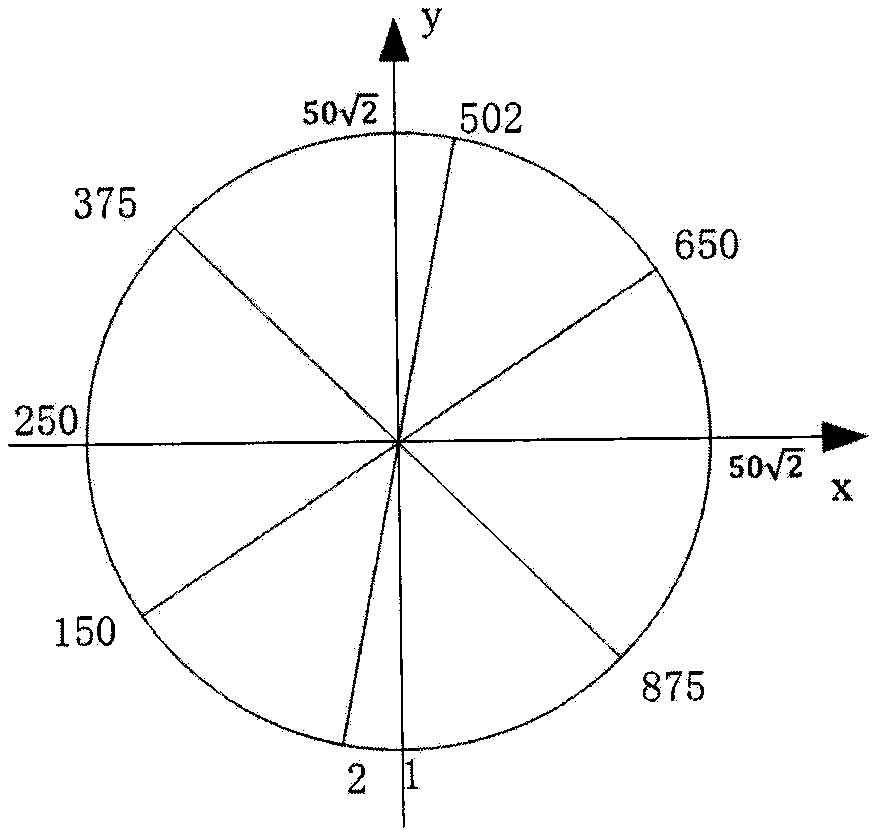

[0050] In step 1, according to the structure of the five-axis CNC machine tool, the installation position of the ballbar is determined, and the accuracy detection is carried out along the preset path by means of three-axis linkage, including steps:

[0051] Step 1.1. First, install the fixture base on the workbench, and install the magnetic base on the fixture base. Then, use the machine tool probe to determine the center of the workpiece tool cup as the origin of the workpiece coordinate system. Finally, move the spindle tool cup to the position of 100mm in the negative direction of the X axis, install one end of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com