Electromagnetic relay

An electromagnetic relay and electrical connection technology, applied in electromagnetic relays, electromagnetic relay details, relays, etc., can solve the problems of complex injection molding process, high preparation cost, relay failure, etc., to simplify the injection molding process, improve the heat dissipation effect, and prolong the use. effect of life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

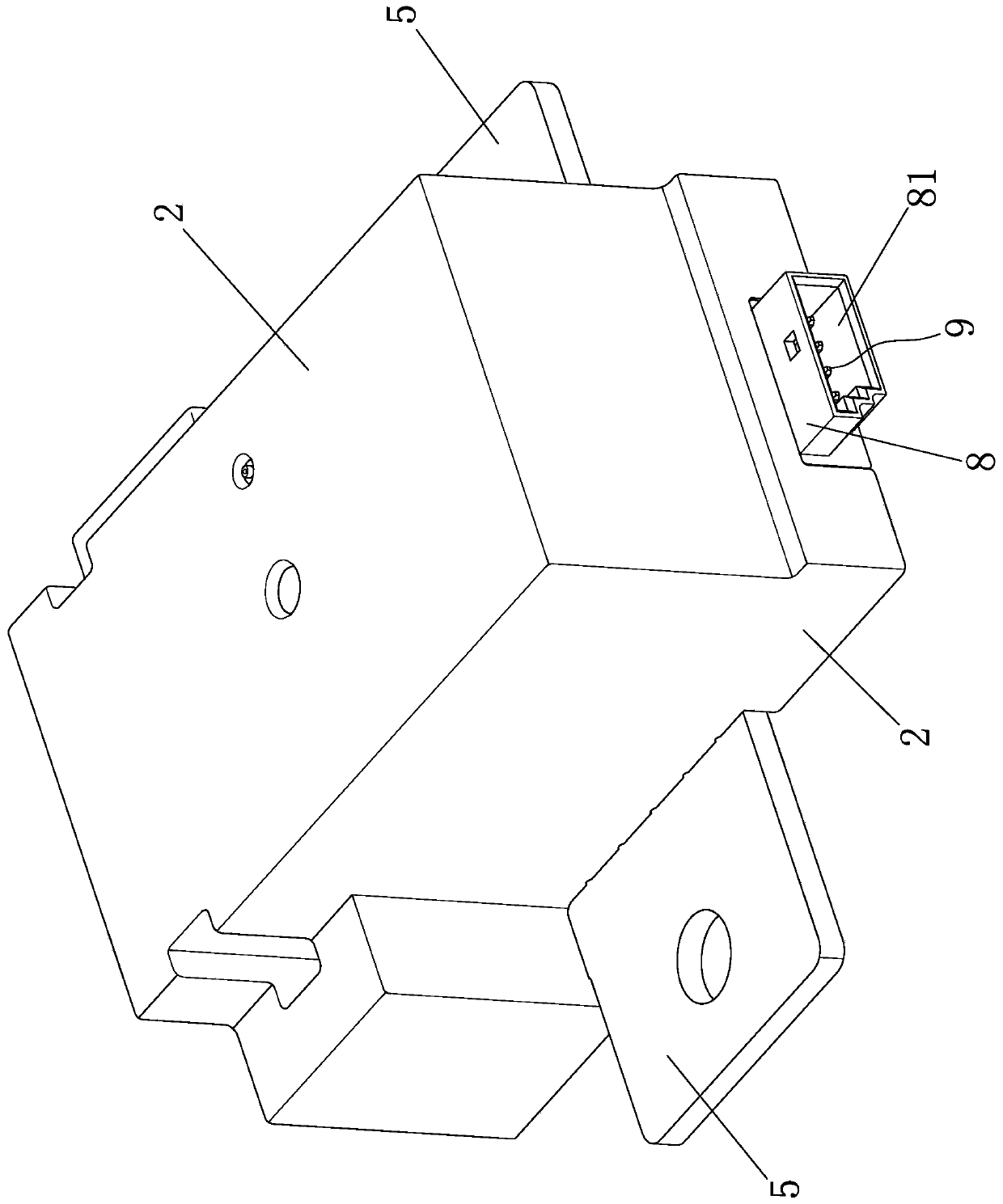

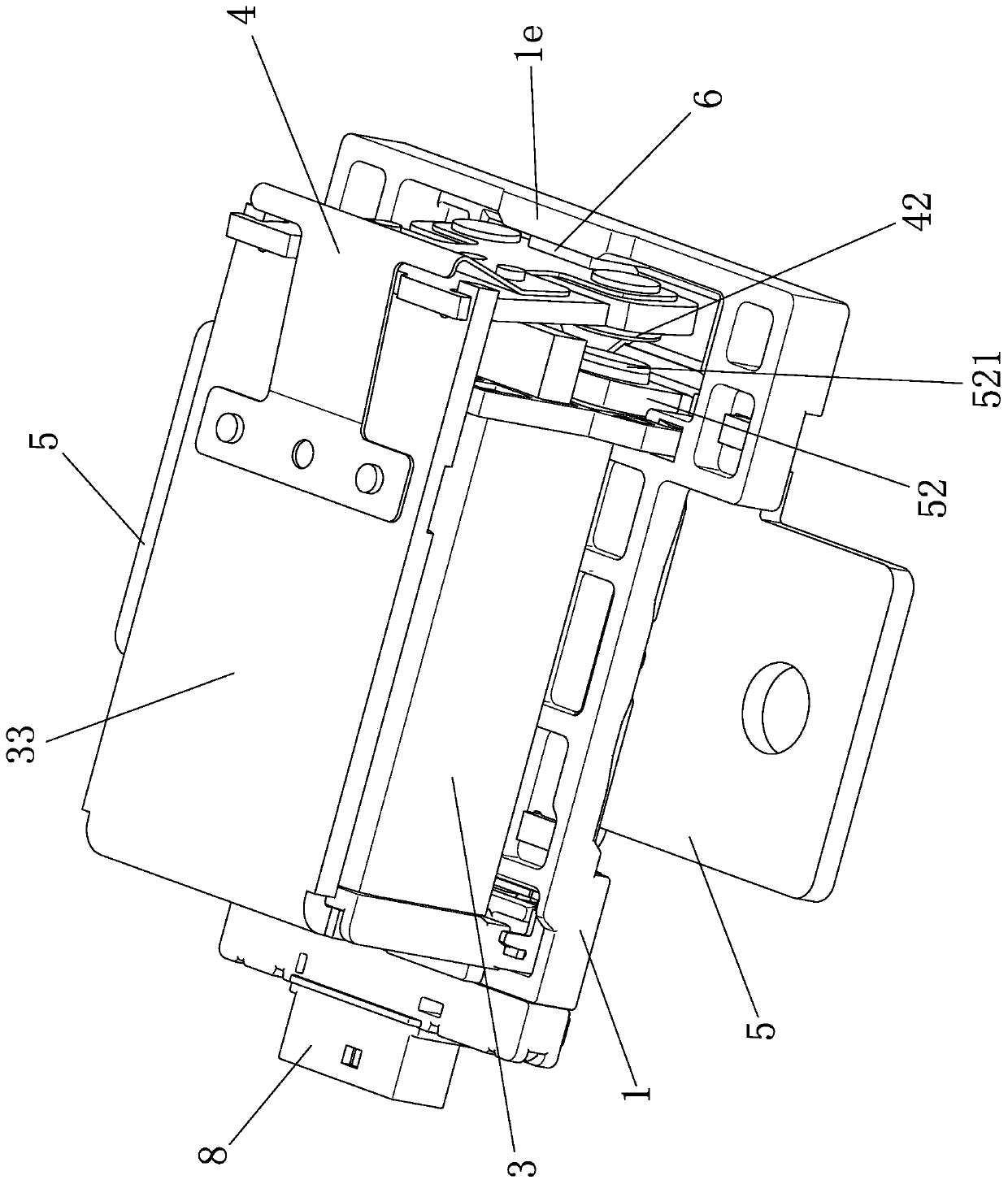

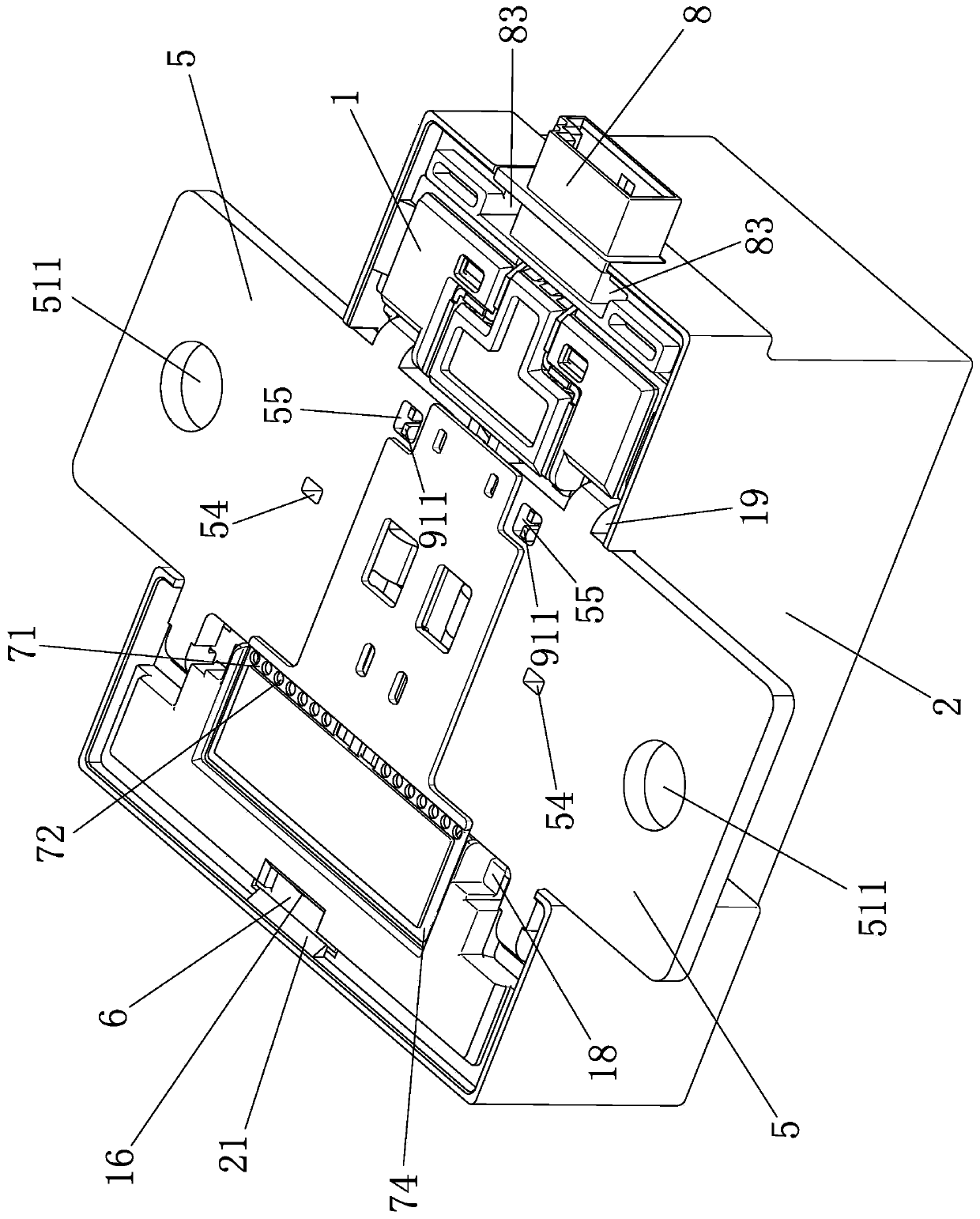

[0063] Embodiment one, Figure 1 to Figure 18 As shown, an electromagnetic relay includes a base 1, a casing 2, a coil 3, a moving reed 4 and two static reeds 5, the casing 2 is clamped and fixedly connected to the base 1, and the inner lower part of the casing 2 is provided with three One clamping limit part 21, three clamping limit parts 21 clamp the base 1, the coil 3 is wound on the coil bobbin 31, the coil bobbin 31 is fixedly connected with the base 1, the coil 3, the coil bobbin 31, and the moving reed 4 Located between the base 1 and the case 2, an iron core 32 is installed in the center hole of the bobbin 31, and a yoke 33 is fixedly connected to the bobbin 31. The yoke 33 is L-shaped, and one end of the yoke 33 is fixedly connected to the bobbin 31. On one side, the other end of the yoke 33 is parallel to the coil 3, and one end of the yoke 33 is provided with two first clipping fixing feet 331, and the lower part of the other side of the coil frame 31 is provided wi...

Embodiment 2

[0088] Embodiment two, Figure 19 to Figure 30 As shown, an electromagnetic relay includes a base 1, a case 2, a coil 3, a moving reed 4 and two static reeds 5, the case 2 is fixedly connected to the base 1, and the coil 3 is wound on a bobbin 31. The coil bobbin 31 is fixedly connected with the base 1, the coil bobbin 31 is located between the base 1 and the cover 2, the center hole of the coil bobbin 31 is equipped with an iron core 32, the coil bobbin 31 is fixedly connected with a yoke 33, and the yoke 33 is L One end of the yoke 33 is fixed to one side of the coil frame 31, the other end of the yoke 33 is parallel to the axial direction of the coil 3, the moving reed 4 is bent along the middle part, and one end of the moving reed 4 is fixed to the yoke 33 On the other end of the moving reed 4, the other end of the moving reed 4 is fixedly connected with an armature 41, and the other end of the moving reed 4 is also provided with two moving contacts 42.

[0089] Each stat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com