Reject valve of reverse osmosis device

A technology of reverse osmosis device, discharge valve, applied in the direction of reverse osmosis, valve device, valve operation/release device, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

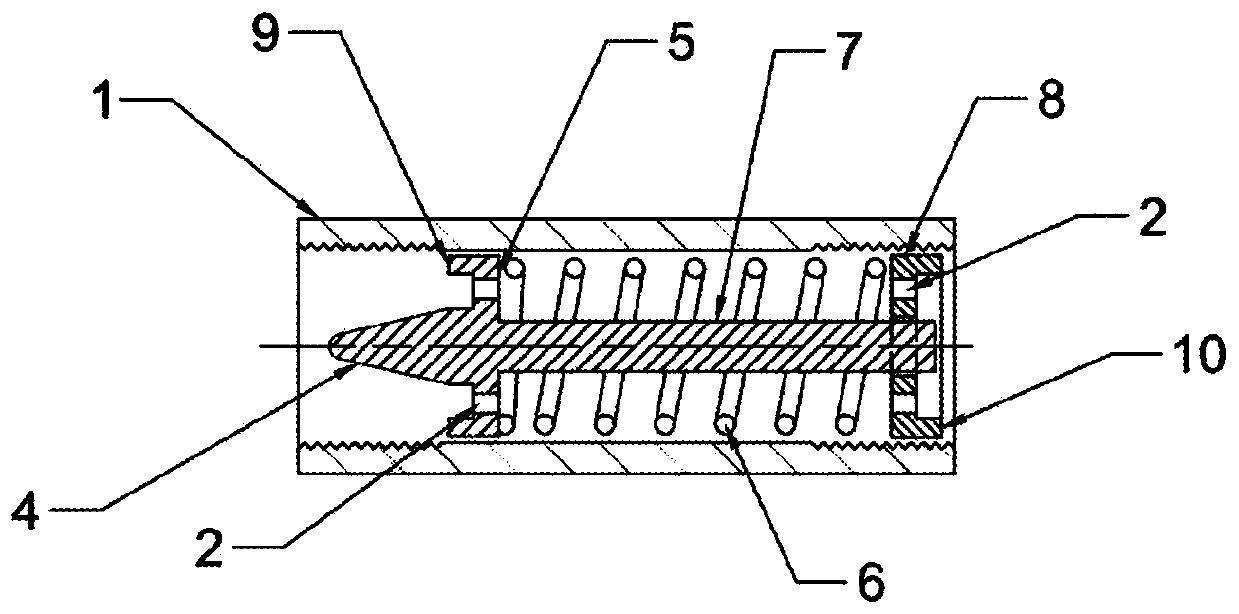

[0021] In the following, refer to the attached Figure 3 to Figure 5 . The invention and the structure of the discharge valve are described by means of examples.

[0022] image 3 A cross-section in the axial direction of the outlet valve is shown. The body 1 comprises freely movable conical needles 4 , 5 , 7 , on whose axis 7 a plate-like element 5 (referred to below as a restrictor plate) is fixedly supported, said plate-like element 5 adjoining the inner wall of the body 1 . On the edge of the restrictor plate 5 on one side of the cone 4 there is an annular gasket 9 or a corresponding protrusion. The guide plate 8 is not attached and adjoins the inner wall of the body 1 at its periphery. In the middle of the guide plate is a hole whose periphery adjoins the shaft 7 of the cone 4 and which has a corresponding washer 10 . These washers 9 , 10 form an integral part of the plates 5 and 8 . Compression spring 6 surrounds shaft 7 and is located between throttle plate 5 and g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com