A kind of hydroxyapatite/phase transition lysozyme coating hybrid material and its preparation method

A hydroxyapatite and hybrid material technology, applied in coatings, pharmaceutical formulations, prostheses, etc., can solve the problems of single source of raw materials, different preparation components, low mechanical strength, etc., and achieves simple and controllable operation process, The effect of controllable crystal morphology and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

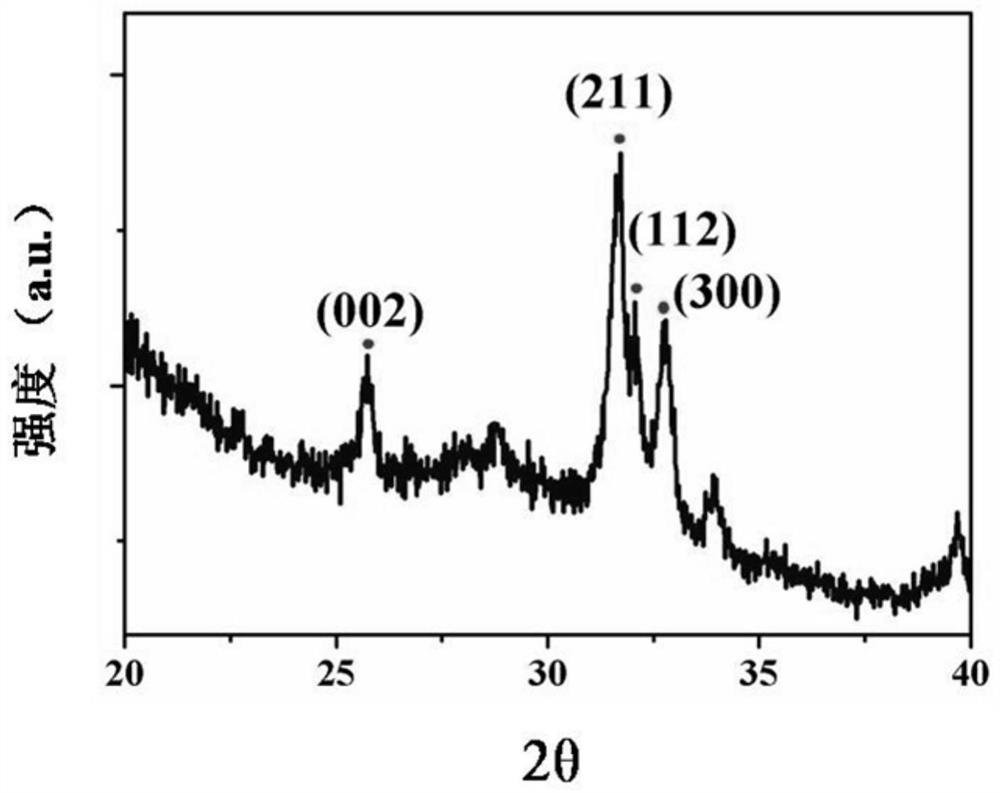

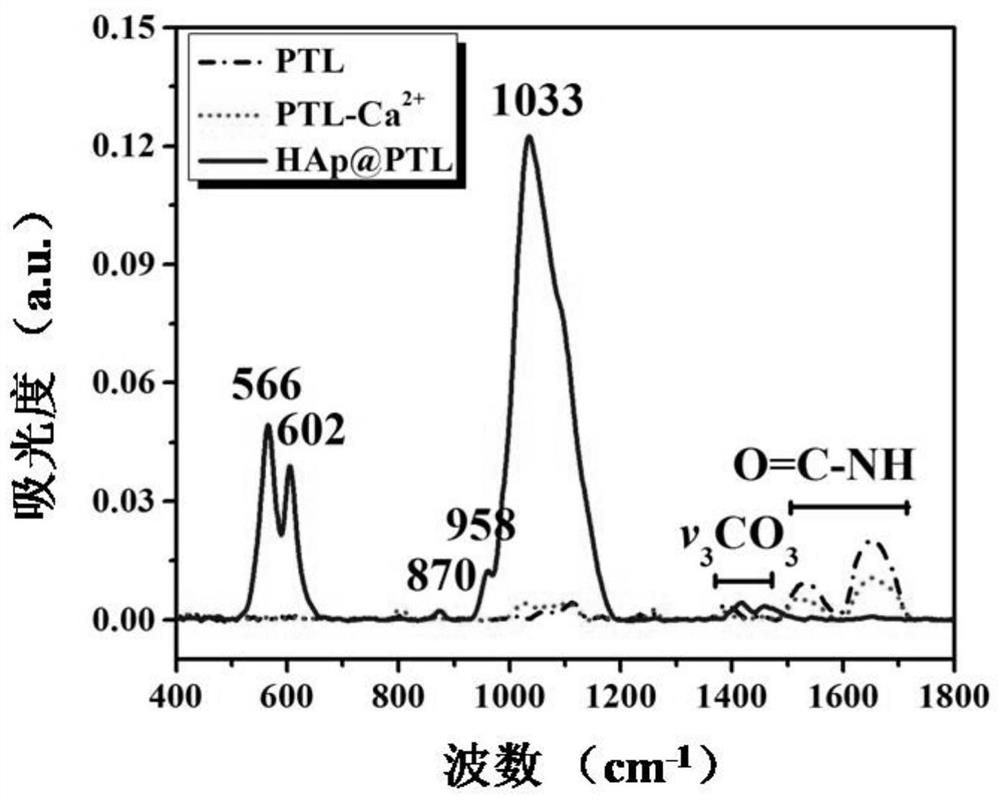

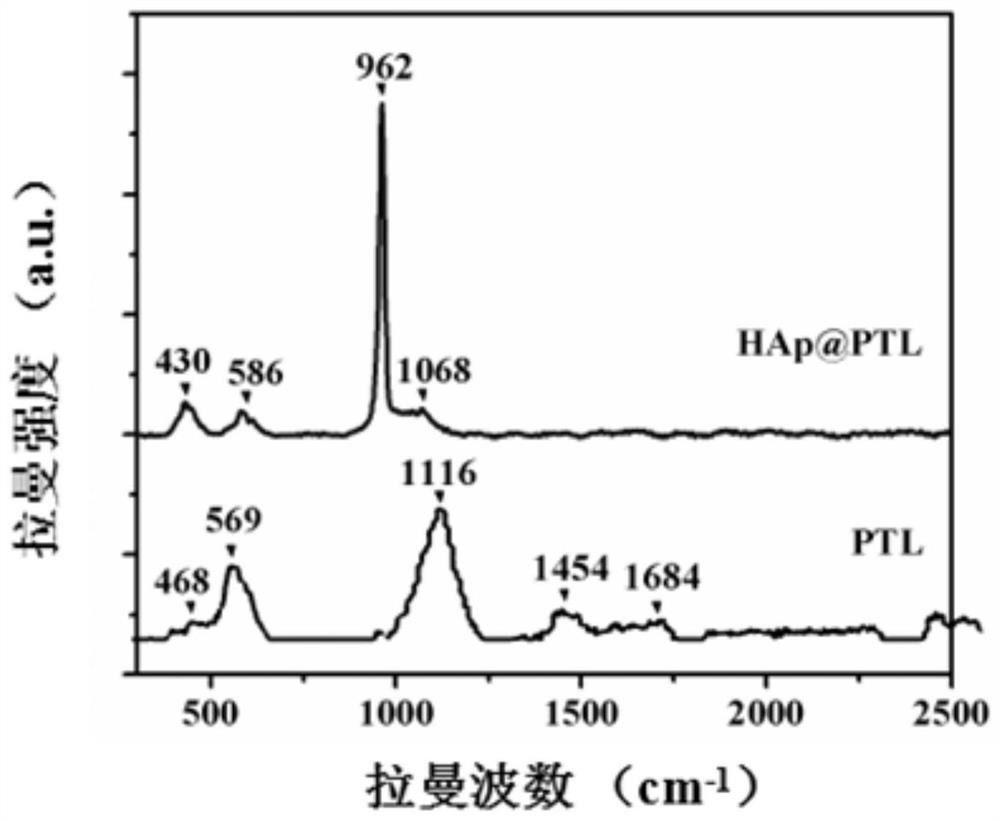

[0037] Add 0.1433g of tris(2-carboxyethyl)phosphine into 10mL of 10mmol / L tris(hydroxymethylaminomethane) buffer solution with a pH value of 7.4, adjust the pH value to 5.8 with NaOH, and prepare 50mmol / L of tris(2- Carboxyethyl) phosphine tris buffer solution; 20mg lysozyme was added to 10mL 10mmol / L tris buffer solution with a pH value of 7.4 to prepare 2mg / mL trihydroxymethyl aminomethane buffer solution of lysozyme Methylaminomethane buffer solution; mix 0.2mL 50mmol / L tris(2-carboxyethyl)phosphine tris buffer solution with 0.2mL 2mg / mL lysozyme tris buffer solution Uniformly, a titanium sheet with a diameter of 1 cm is in contact with the surface of the mixed solution, and left at room temperature for 50 minutes, a layer of lysozyme two-dimensional nano-film (PTL) is adhered on the surface of the titanium sheet, and its thickness is about 50nm. Fully immerse the titanium sheet with lysozyme two-dimensional nano film on the surface in 0.02mol / L calcium chloride aqueous sol...

Embodiment 2

[0040] In the present embodiment, the titanium sheet of embodiment 1 is used ZrO 2 Replacement, other steps are identical with embodiment 1, obtain HAp@PTL coated hybrid material (see Figure 8 ).

Embodiment 3

[0042] In this example, the titanium sheet in Example 1 was replaced with a medical catheter, and the other steps were the same as in Example 1 to obtain a HAp@PTL coated hybrid material (see Figure 9 ).

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com