Measuring Probes for Beam Scanning

A beam and probe technology, applied in the field of scanning beam or laser beam devices, can solve the problems of inaccurate scanning results, changes in beam characteristics, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

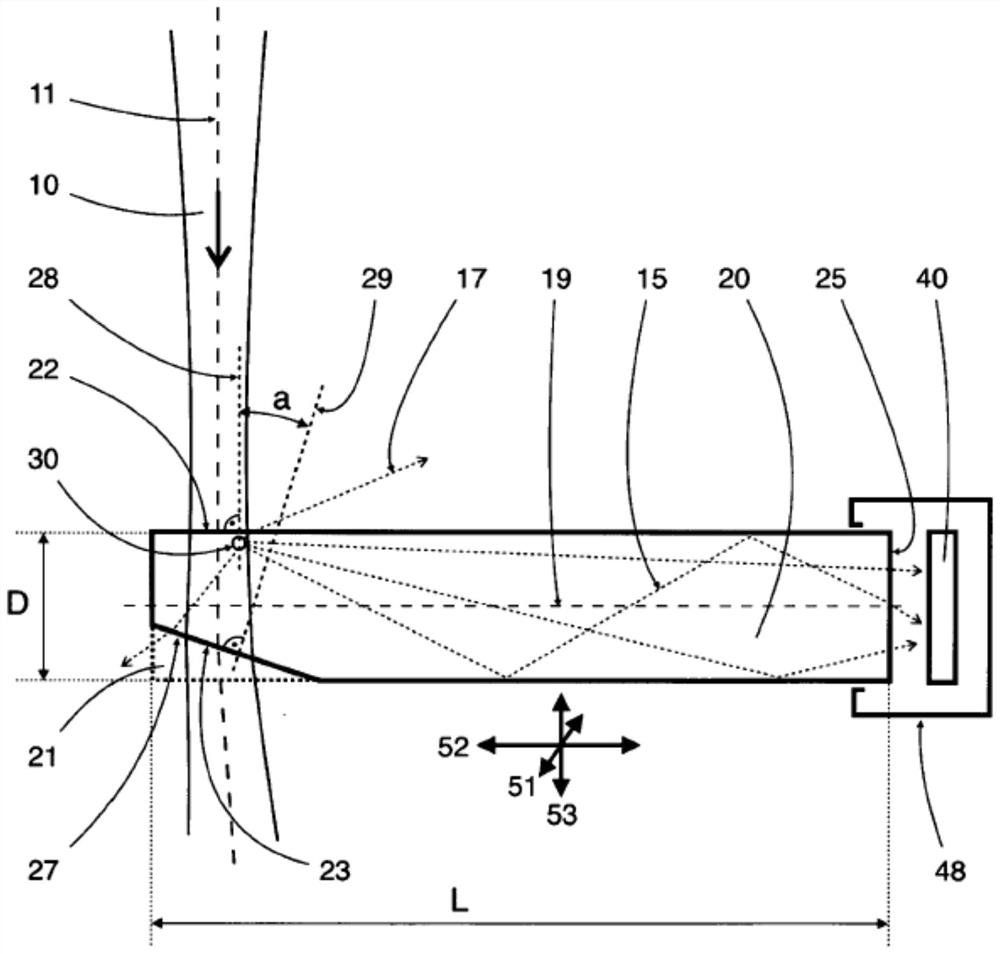

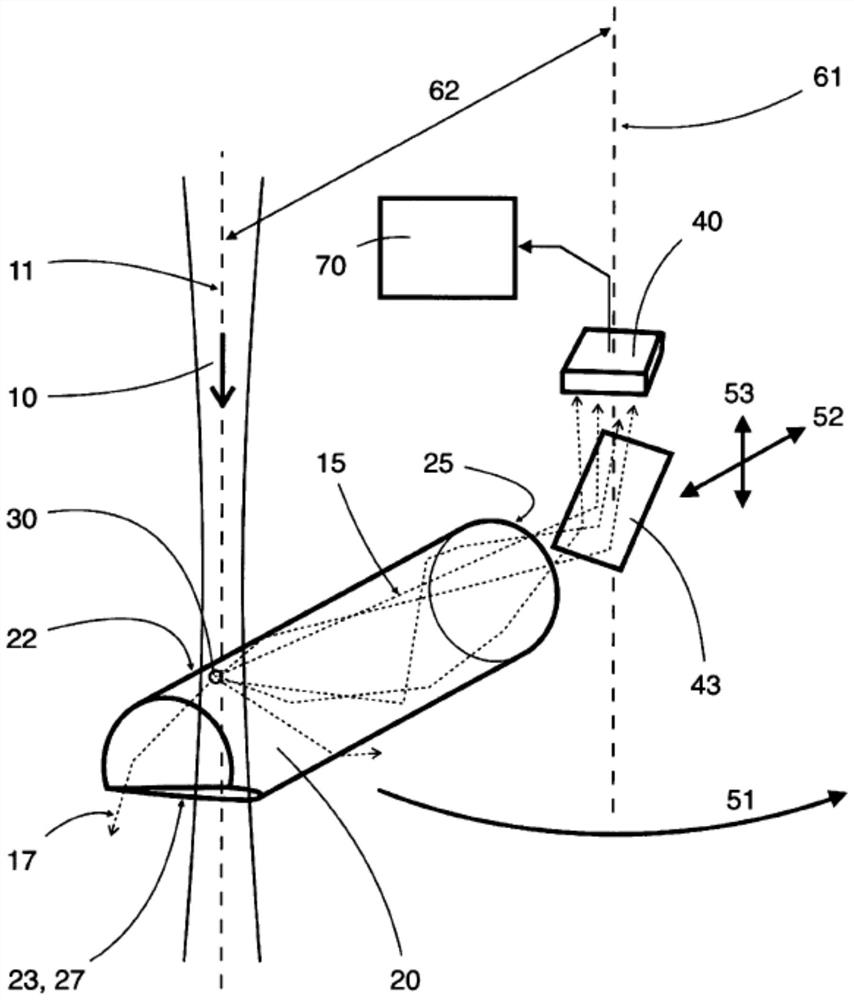

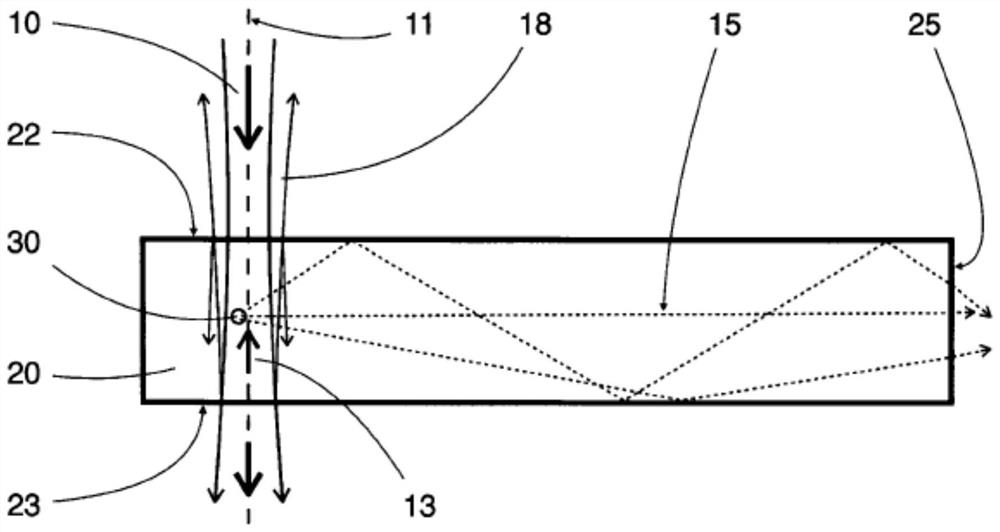

[0099] The invention proposes a solution to the problem that the devices for beam analysis known from the prior art are inaccurate or can be destroyed when applying beams or laser beams with very high power, and Consequences may occur due to scattered light, for example due to multiple reflections with erroneous signals. Instead, a device for scanning a light beam is provided which is suitable for determining geometric parameters of high-power or high-power-density laser beams, is insensitive to scattered light and enables measurements with a high signal-to-noise ratio.

[0100] In order to solve this problem, a device for scanning a light beam 10 is proposed, comprising a scanning volume 20, a probe area 30, a detector 40 and means for providing relative motion. The scanning body 20 consists of a material which is optically transparent to the light beam 10 . The scanning body 20 has a beam entrance surface 22 , a beam exit surface 23 and a sample light exit surface 25 . The...

PUM

| Property | Measurement | Unit |

|---|---|---|

| angle | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com