Molding device for skull defect model with definite depth and method

A skull and model technology, applied in the field of skull defect model modeling equipment, can solve the failure rate and other problems, and achieve the effects of avoiding damage, simple use, and good support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

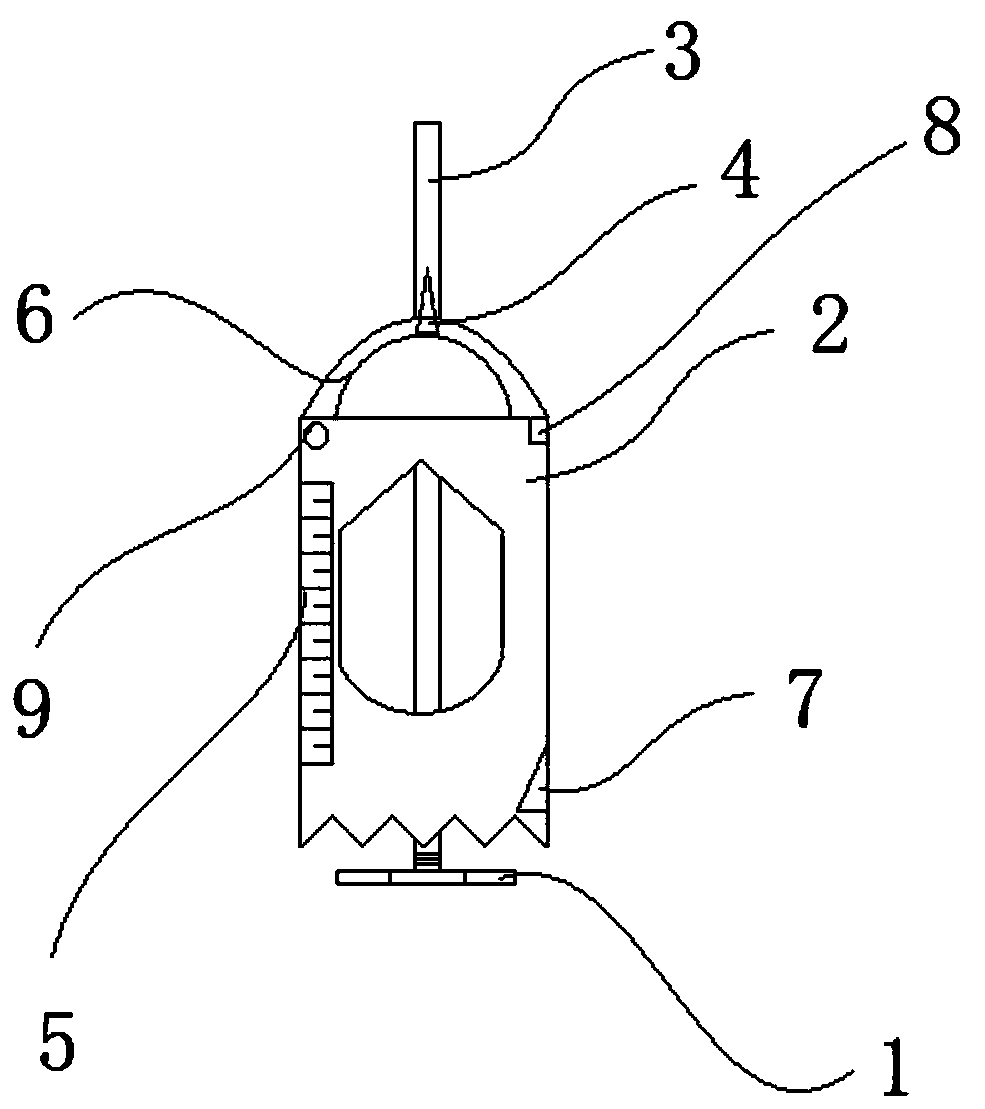

[0034] Such as figure 1 As shown, a definite depth skull defect model modeling equipment includes a drill bit 1, a sleeve 2 and a control source 3. The control source 3 includes but is not limited to a power cord, the drill bit 1 penetrates the sleeve 2, the drill bit 1 and the sleeve A connecting piece 4 is provided between the barrels 2. The connecting piece 4 includes but is not limited to expansion screws. The sleeve 2 is a hollow cylindrical structure. The diameter of the sleeve 2 is larger than the diameter of the drill bit 1. The length is less than the length of the drill bit 1, and the sleeve 2 is made of hard material.

[0035] The diameter of the sleeve 2 is 1 mm-1.5 mm larger than the diameter of the drill bit 1, and the length of the sleeve 2 is 1 mm-1.5 mm smaller than the length of the drill bit 1.

[0036] Two through holes are provided on the surface of the sleeve 2 to facilitate cleaning and facilitate the release of heat during the working process of the drill b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com