A welding method for flat butt joints of q370qd and q500qe bridge steel

A welding method and technology of butt joints are applied in welding equipment, welding medium, welding equipment, etc. to achieve the effects of good appearance of the weld, excellent low temperature impact toughness, and good fusion of the weld.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Attached below Figure 1-6 The present invention will be further described in detail with specific embodiments.

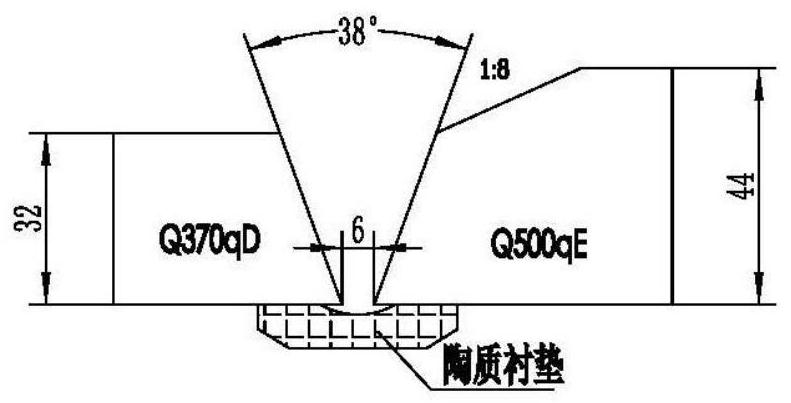

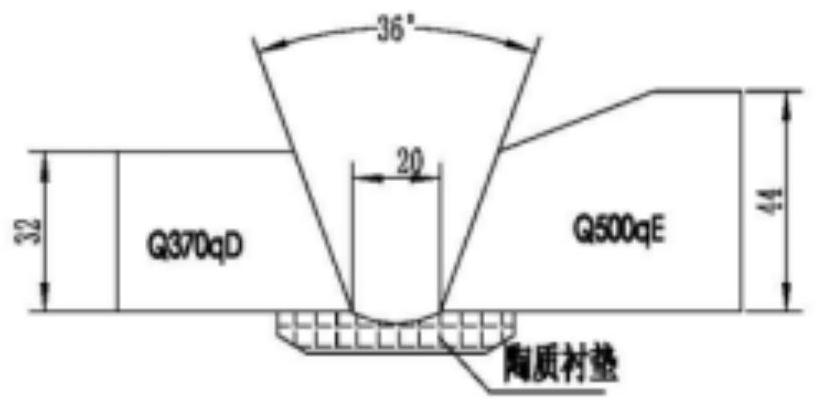

[0034] A welding method for flat butt joints of Q370qD and Q500qE bridge steel, the joint form is: the plate thickness of Q370qD and Q500qE bridge steel at the joint is both 21-41mm, the joint groove form is V-shaped groove, and the groove angle is 35 °~38°, the root gap is 6mm-30mm, and the groove angle decreases with the increase of the root gap;

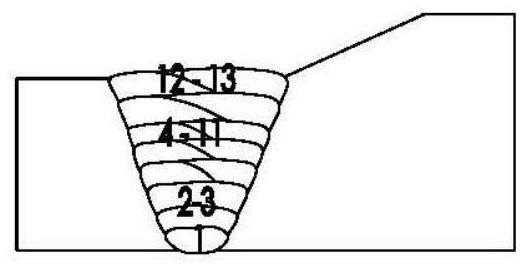

[0035] The present invention adopts the solid welding wire argon-rich gas shielded welding as the base, and the flux-cored welding wire CO 2 For the composite welding method of gas shielded welding filling and covering, select solid welding wire and flux-cored welding wire with mechanical properties equivalent to those of Q500qE bridge steel and match the chemical composition, and continuously weld Q370qD and Q500qE butt joints through multiple layers and multiple passes. The specific welding Proceed as follow...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com