Automatic deburring equipment

A deburring and equipment technology, applied in metal processing equipment, grinding/polishing equipment, grinding drive devices, etc., can solve the problems of difficult waste recycling, low work efficiency, unsafe use, etc., to achieve good deburring effect, The effect of processing large parts is convenient and safe to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

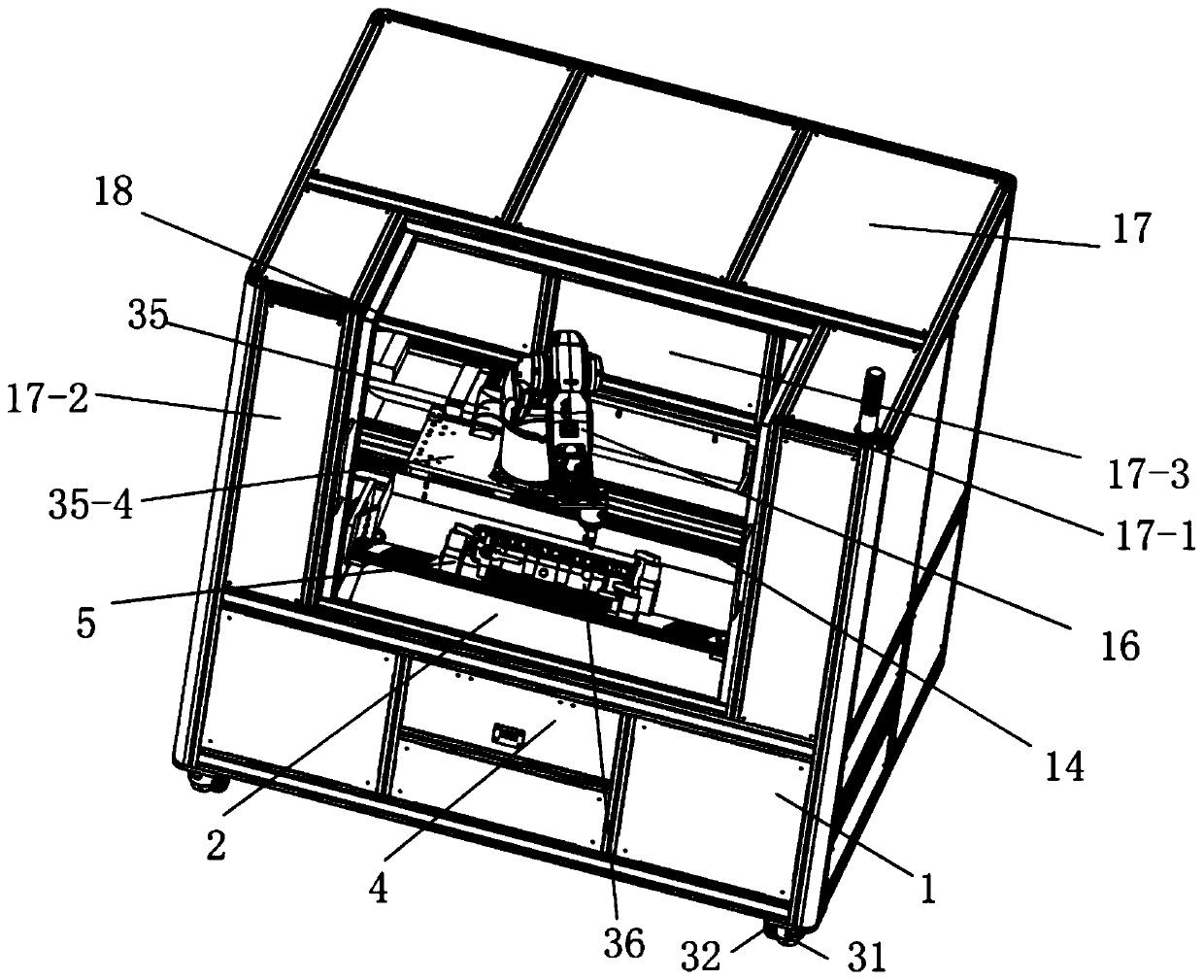

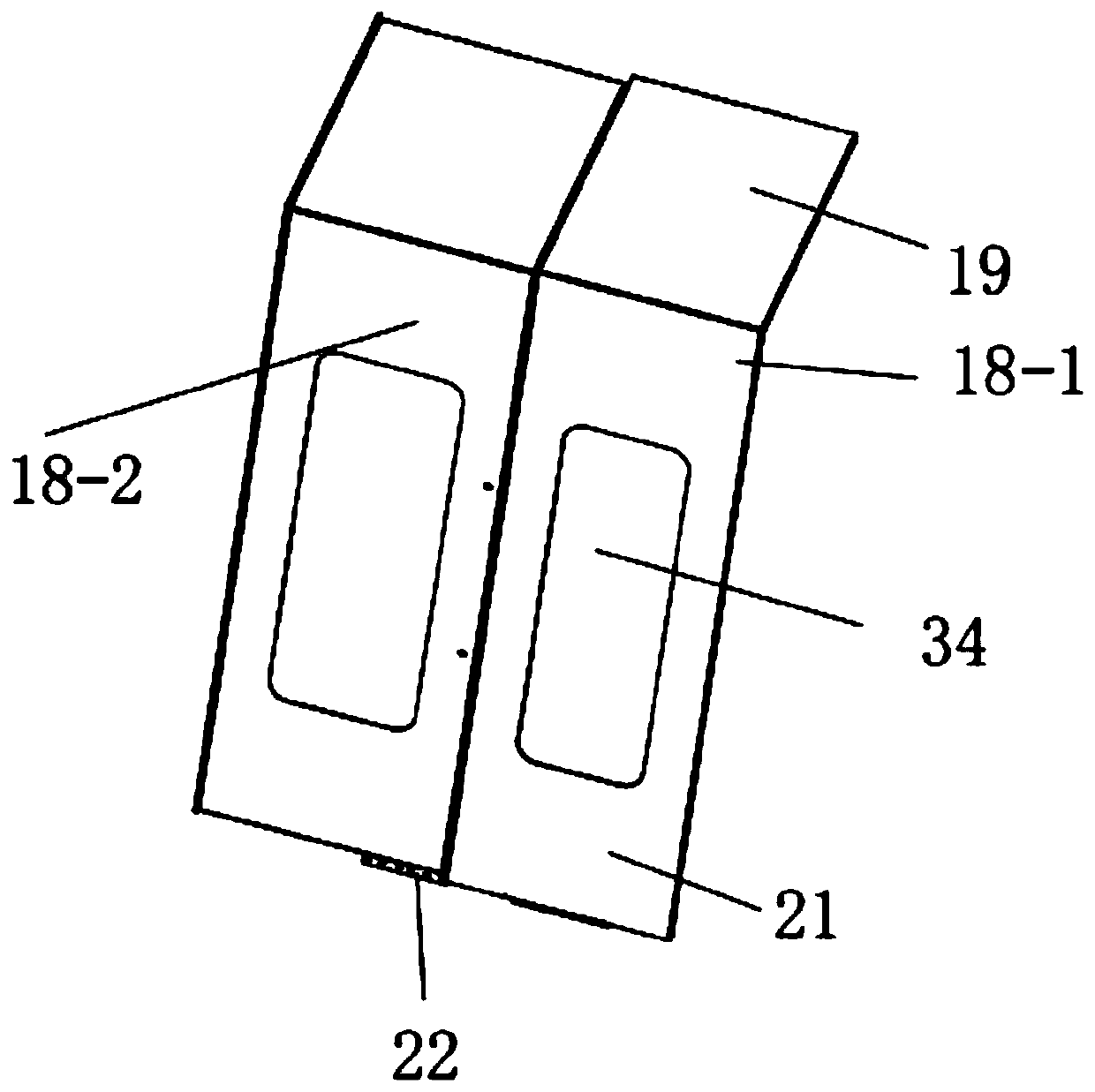

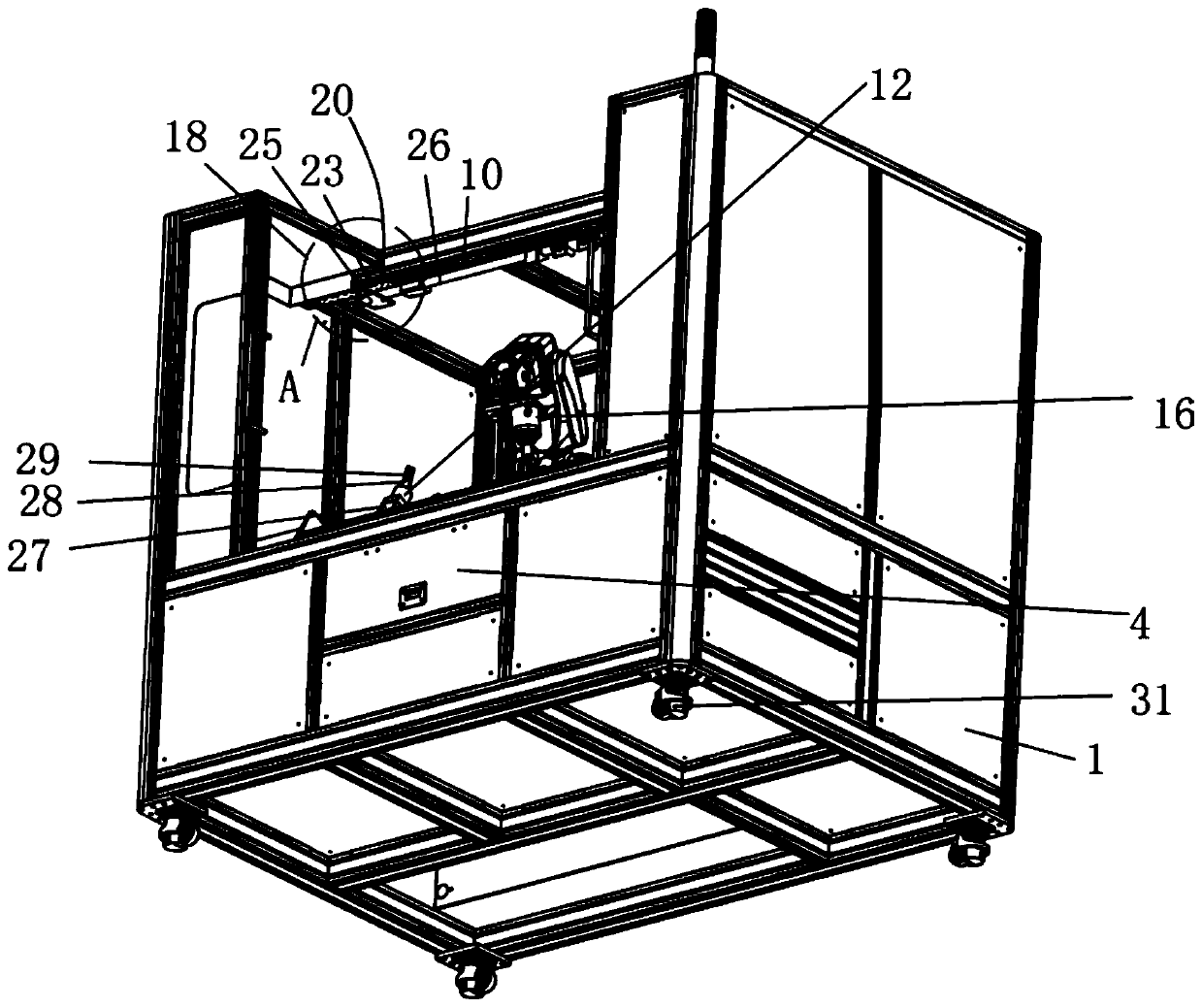

[0027] Such as Figure 1-Figure 10 As shown, a kind of automatic deburring equipment provided by this embodiment includes a frame 1, on which a waste material recovery funnel 2 with a bottom inclined downward is arranged, and the bottom plate of the waste material recovery funnel 2 is inclined. The lower end of the bottom plate of the recovery funnel 2 is provided with a discharge port 3, and a pull-out waste recovery drawer 4 is provided on the frame 1. 2 is provided with a product tooling fixture 5, the product tooling fixture 5 includes two first mounting brackets 6 of C-shaped structure fixed on the frame 1, and the two first mounting brackets 6 are respectively located in the waste recycling On both sides of the funnel 2, a first connecting plate 8 is rotatably connected between each first mounting bracket 6 through a first rotating shaft 7, and a second connecting plate located above the waste recovery funnel 2 is fixed between the two first connecting plates 8. Connect...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap