Pinus densiflora board shallow layer carbonization equipment

A red pine board, shallow layer technology, applied in the field of red pine board shallow carbonization equipment, can solve the problems of difficult to guarantee the color of red pine board, low work efficiency, uneven carbonization, etc., to achieve high work efficiency, reduce friction, and uniform carbonization. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

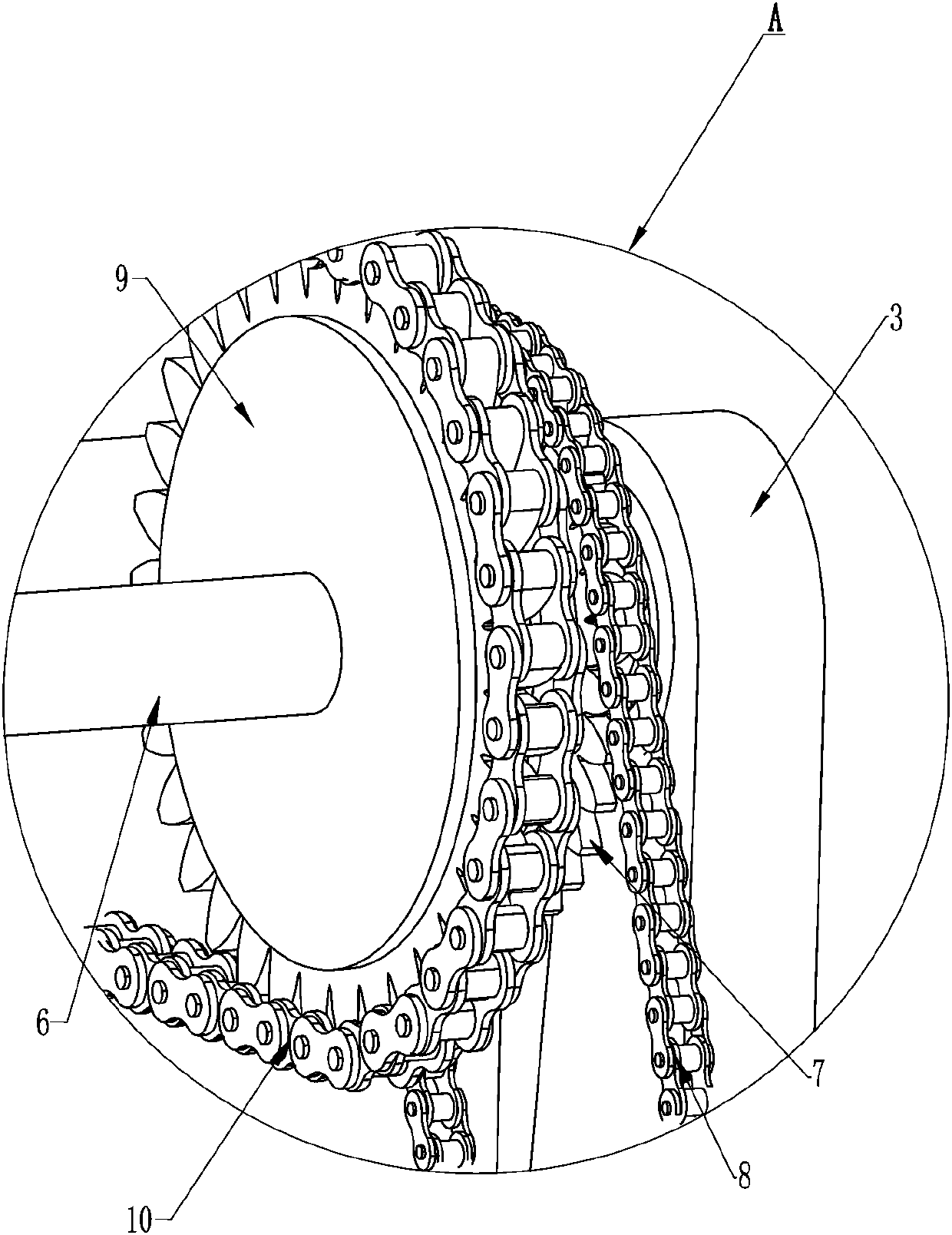

[0024] A kind of shallow layer carbonization equipment of red pine board, such as Figure 1-5 As shown, it includes a base 1, a frame 2, a support frame 3, a biaxial motor 4, a transmission assembly, a connecting plate 11, a first fixed block 12, a flat nozzle oxygen welding torch 13, a clamping assembly, a support rod 18, and a blanking assembly. Box 19, baffle plate 20, guide ring 22 and second fixed block 23, base 1 top is provided with frame 2 and biaxial motor 4, frame 2 is positioned at the left side of biaxial motor 4, and base 1 top four corners are all fixedly connected with The support frame 3, the support frame 3 is located between the frame 2 and the biaxial motor 4, the support frame 3 is provided with a transmission assembly, the transmission assembly is used to transmit power, the transmission assembly is provided with a connecting plate 11, and the connecting plate 11 is fixed with The first fixed block 12, the transmission assembly is also provided with a clam...

Embodiment 2

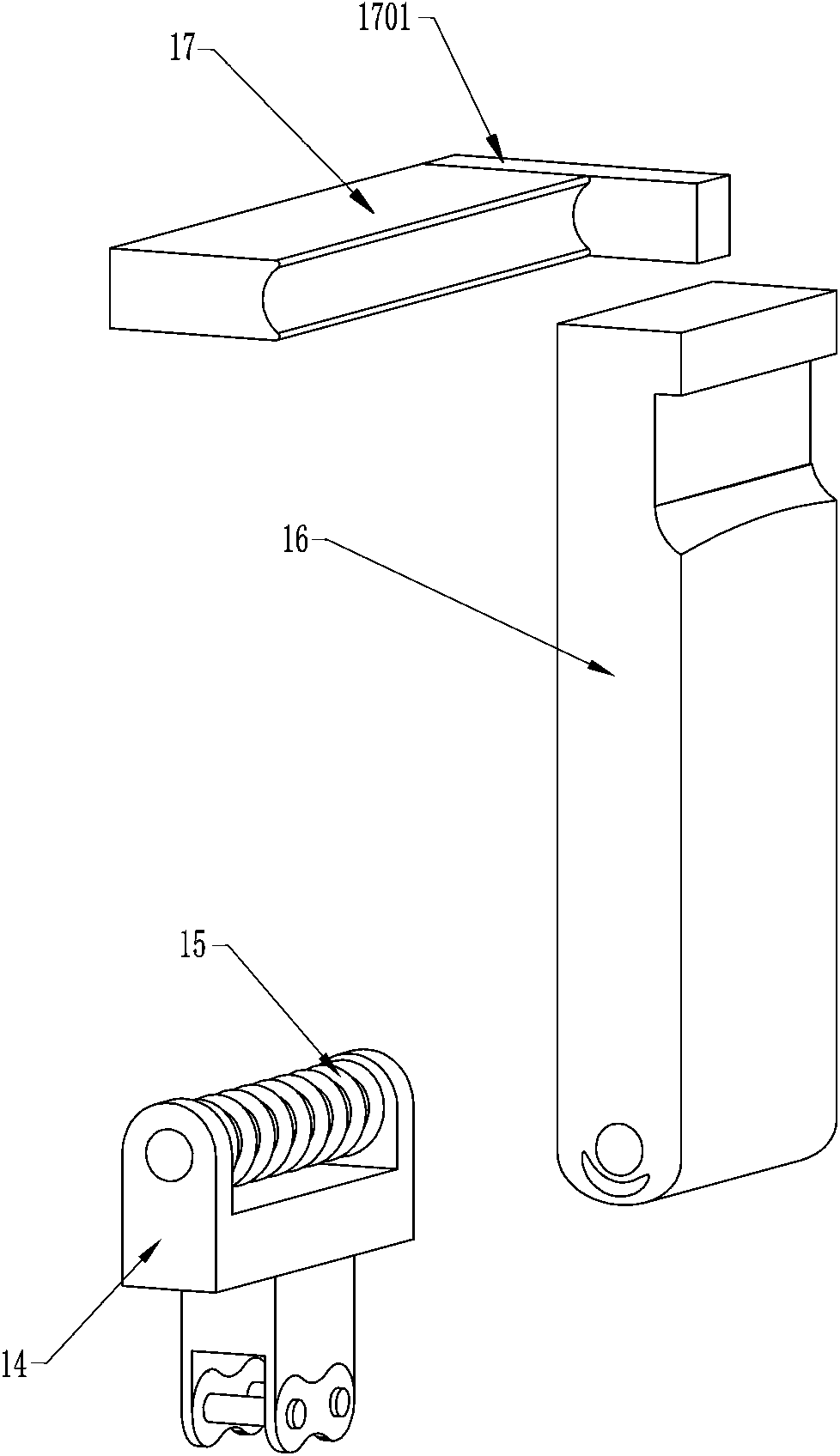

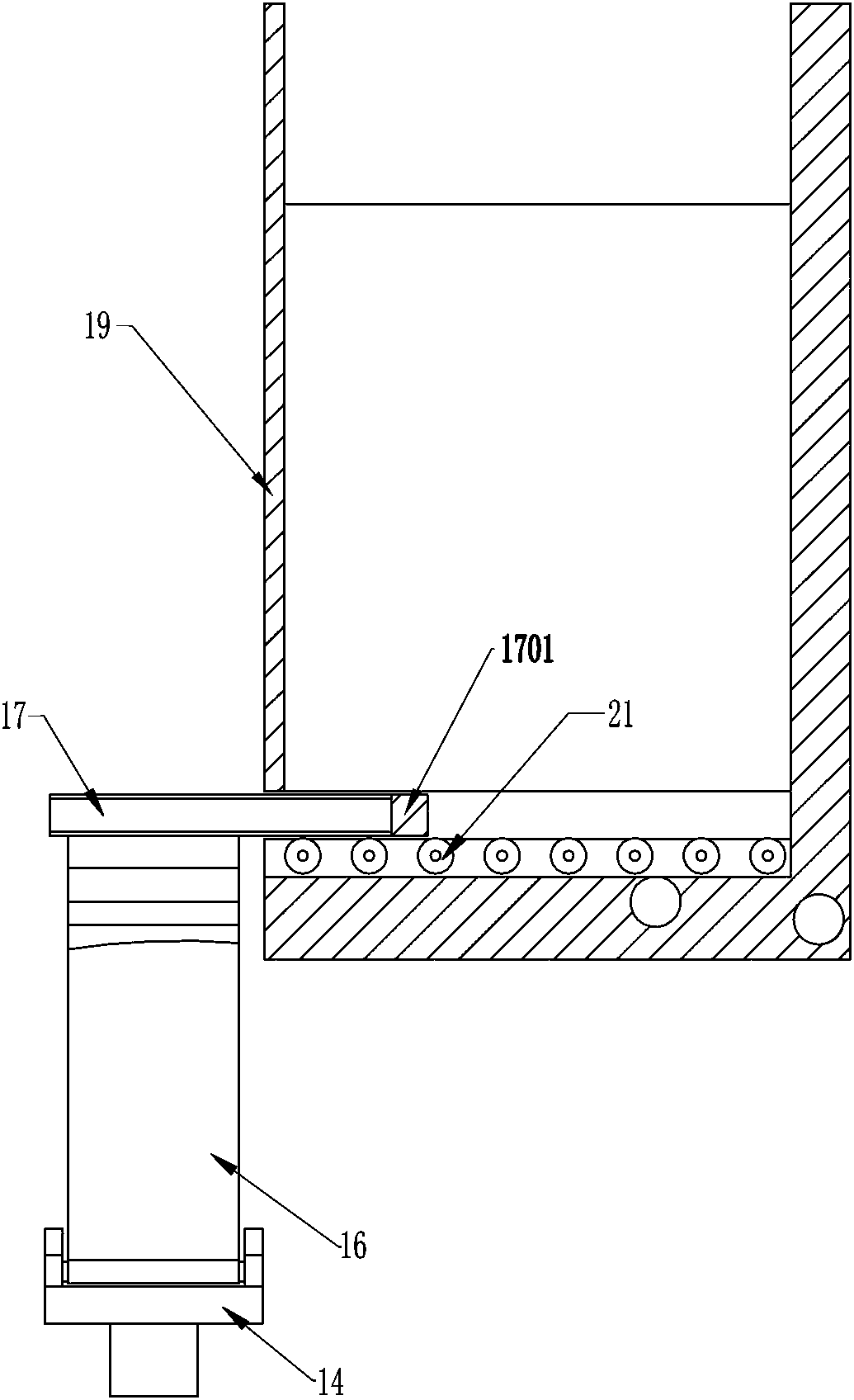

[0031] Such as Figure 1-3 As shown, it also includes a push rod 1701 and a roller 21 , the clamp block 17 is fixedly provided with a push rod 1701 , and the bottom of the feeding box 19 is rotatably connected with a roller 21 .

[0032] When the connecting block 16 is separated from the guide ring 22, the clamp block 17 clamps the red pine board, the push rod 1701 pushes the red pine board, and the roller 21 can reduce the friction between the red pine board and the unloading box 19, so that the red pine board can be removed more smoothly The blanking box 19 will not cause the clamping block 17 to clamp the red pine board because the friction force is too large.

[0033] Also include bearing block 24, second rotating shaft 25, first gear 26, drive wheel 27, belt 28, the 3rd rotating shaft 29, second gear 30 and conveyor belt 31, base 1 top is provided with four bearing blocks 24, four The bearing blocks 24 are all located between the four support frames 3, and the second rot...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com