Ink-jet printing device for corrugated board and printing method

An inkjet printing equipment and corrugated cardboard technology, applied in printing devices, printing and other directions, can solve the problems of long replacement cycle, long interval time, and various structural combinations, and achieve no friction damage consumption, strong scale adaptability, The effect of real application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0055] The present invention will be further described in detail below with reference to the accompanying drawings and specific embodiments to facilitate a clear understanding of the present invention, but they do not limit the present invention.

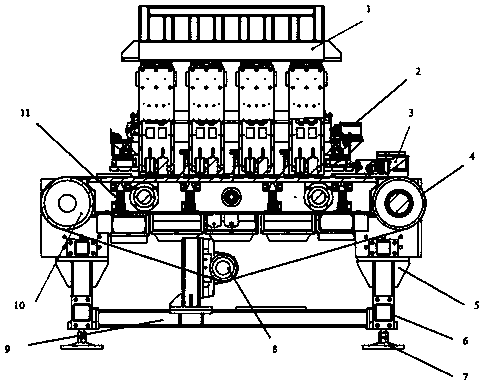

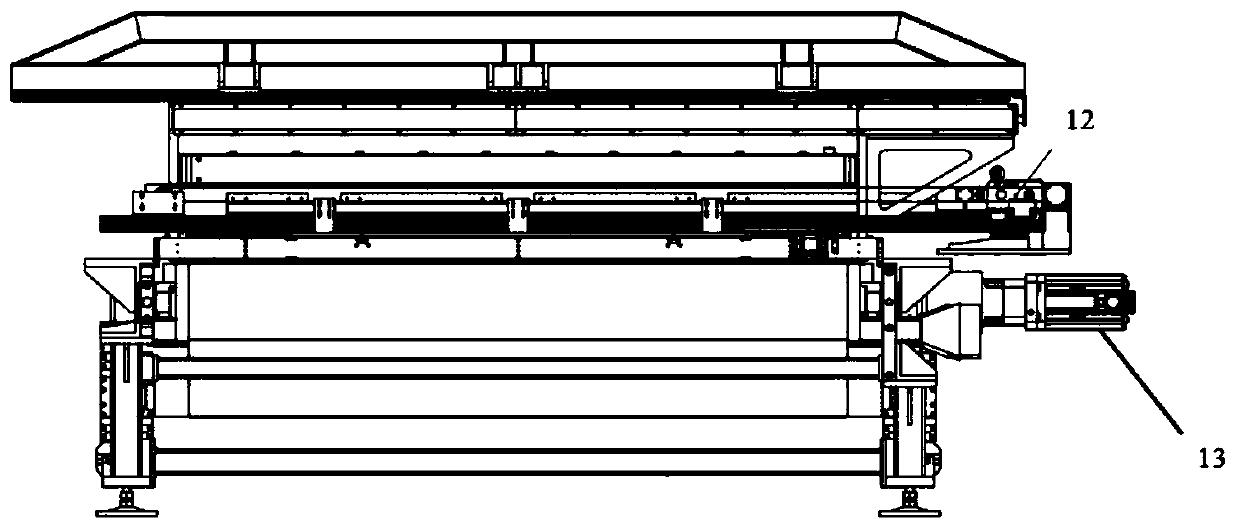

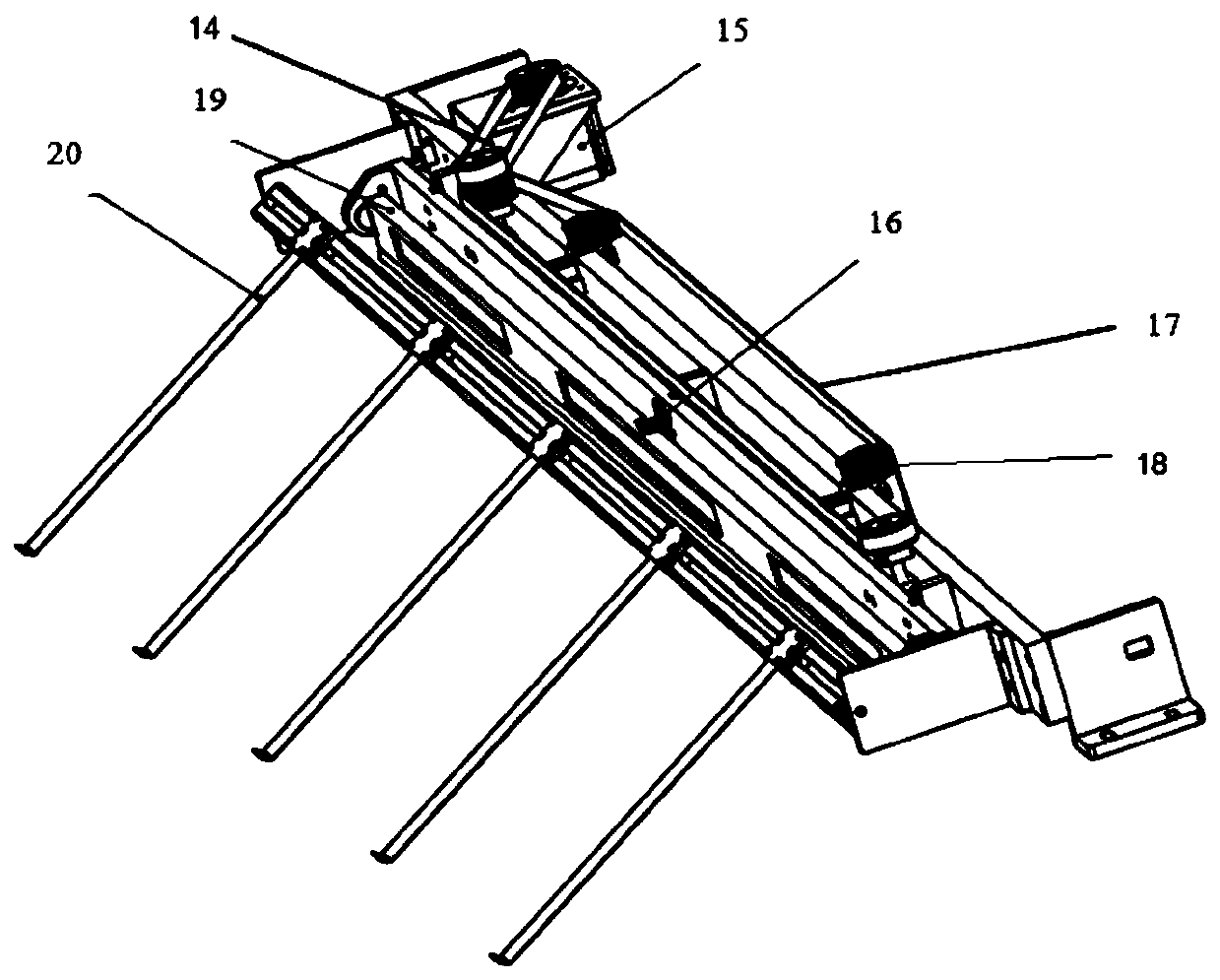

[0056] See figure 1 with figure 2 As shown, an inkjet printing device for corrugated cardboard includes a frame, a cardboard height-limiting mechanism, a conveying belt mechanism, a printing mechanism and a nozzle wiping mechanism; the conveying belt mechanism includes a conveying belt 21 and a belt pulley 10 , The belt tail wheel 4, the second motor 13, and the negative pressure adsorption box; the belt head wheel 10, the belt tail wheel 4 are connected by a transmission belt 21, the belt head wheel 10 and the second motor 13 output Drive connection, the negative pressure suction box is used to firmly adsorb the cardboard on the surface of the conveying belt 21; the cardboard height limit mechanism includes a third motor 15, a timing ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com