Spiral auxiliary cable positioning and shaping ore mixed transportation hose system

A hose and spiral technology, which is applied in the field of ore mixed transportation hose system with spiral auxiliary cable positioning and shaping, can solve the problems of affecting the service life of flexible risers, the bending stiffness of flexible hoses is small, and affecting the flow of ore slurry in risers. Achieve the effects of increasing reliability and operability, facilitating offshore installation, and improving service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

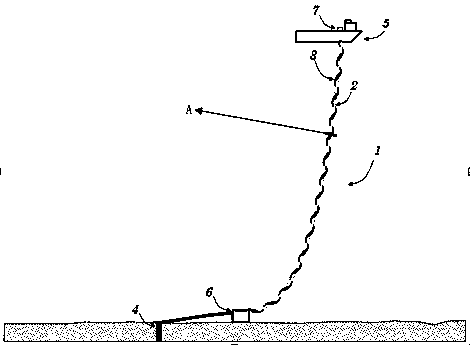

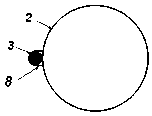

[0013] Such as Figure 1-2 As shown, the ore mixed transportation hose system with spiral auxiliary cable positioning and shaping includes ore transportation hose 2, mooring cable 3, mooring cable tensioning system, and fixing device 8 for ore transportation hose 2 and mooring cable 3 . The fixing device 8 is a guide groove, a guide pipe or a fixing ring. The mooring line 3 is fixed on the outer surface of the ore transport hose 2 in the form of spiral winding through the fixing device 8, which is convenient for installation at sea. The ore transport hose 2 and the mooring line 3 can move relatively. When the tension of the mooring line 3 is adjusted by the tensioner 7, the length of the mooring line 3 in the water changes accordingly, and relatively moves along the outer surface of the ore transport hose 2 to change the shape of the ore transport hose 2 in water. As the tension of the mooring line 3 changes, the axial stiffness of the mooring line 3 also changes. When the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com