Automatic code box machine

A box stacker and automatic technology, applied in the box stacker field, can solve the problems of unsuitable labor intensity for modern production needs, low efficiency and high cost, and achieve the effects of avoiding limited loading height, high flexibility and convenient operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described in detail below in conjunction with the drawings and embodiments. The same parts are indicated by the same reference numerals. It should be noted that the words "front", "rear", "left", "right", "upper" and "lower" used in the following description refer to the directions in the drawings, and the words "bottom" and "top" "," "inner" and "outer" respectively refer to directions toward or away from the geometric center of a particular component.

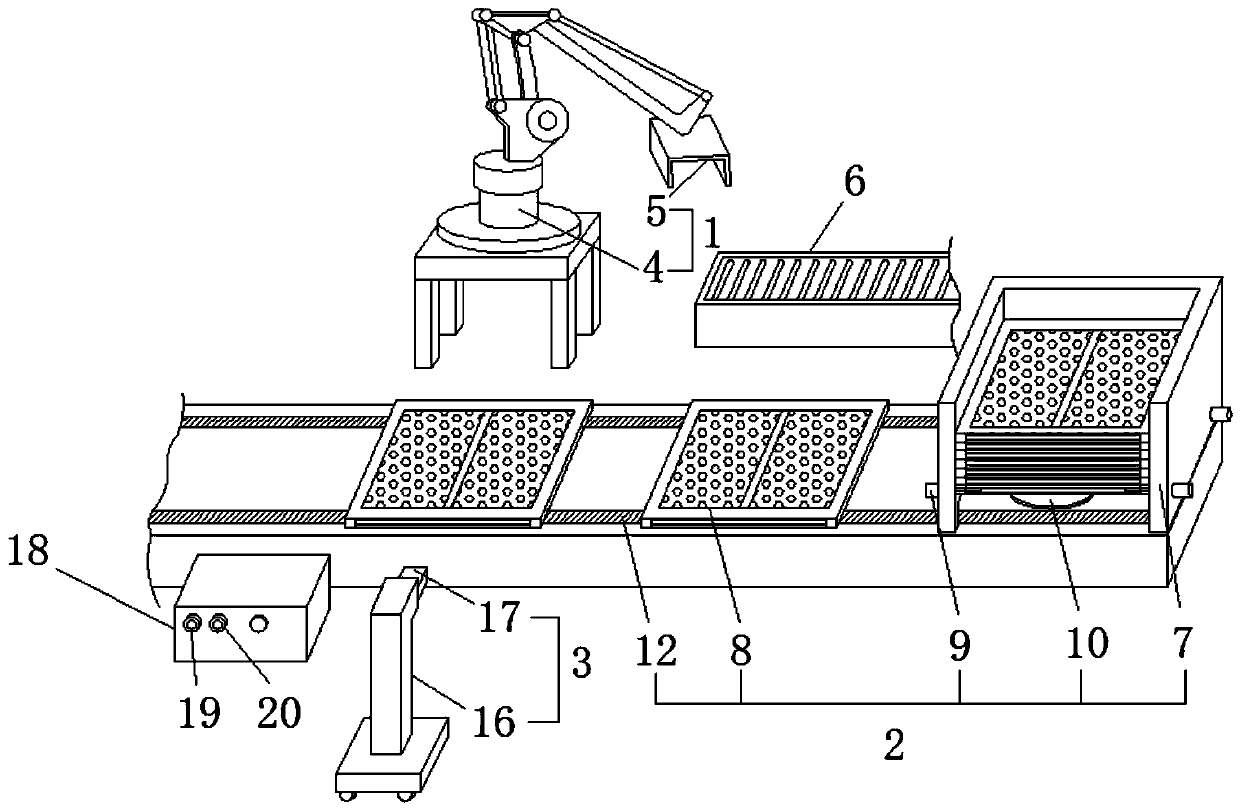

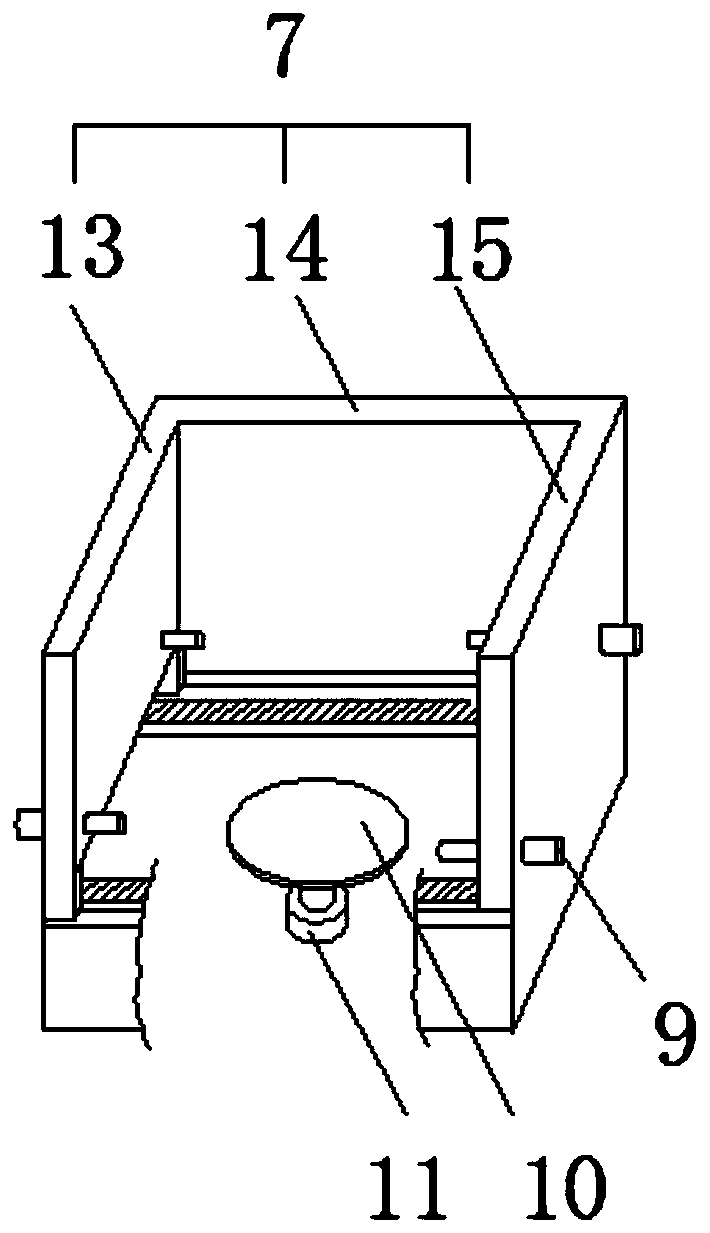

[0022] See Figure 1-3 , The present invention provides a technical solution: an automatic box palletizer, including a mechanical gripper device 1 for grabbing cartons for palletizing, a pallet conveying device 2 for providing pallets, and a detecting device 3 for detecting the height of the cartons;

[0023] The mechanical gripper device 1 includes a base 4 and a mechanical gripper 5. The base 4 is connected with the mechanical gripper 5 to complete the carton palletizing work on the...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap