Method for controlling drilling track of flagstone oil and gas reservoir horizontal well

A trajectory control, oil and gas reservoir technology, applied in directional drilling, earthmoving, wellbore/well components, etc., can solve the problem that the drilling trajectory easily deviates from the target oil layer, etc., and achieve the effect of improving the production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

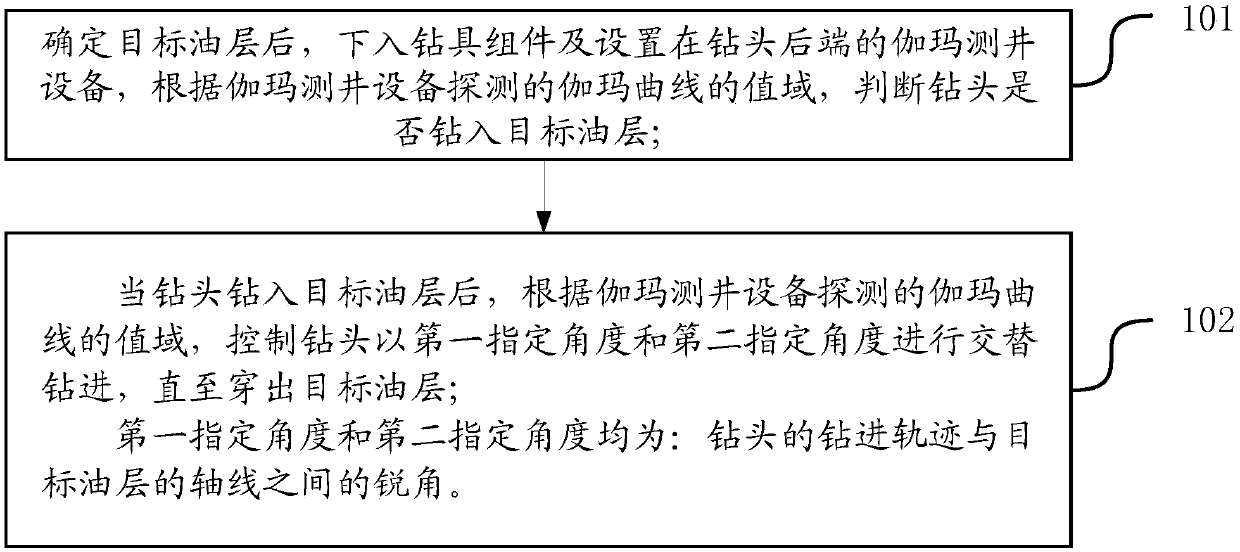

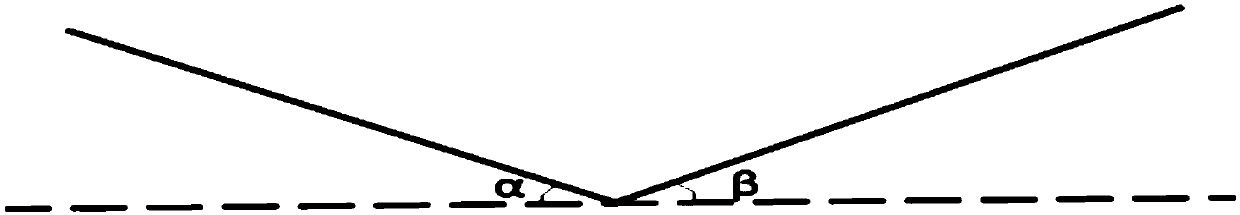

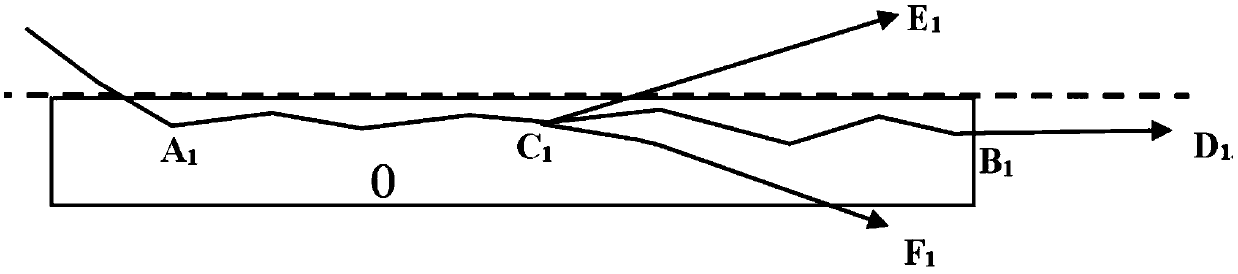

[0072] This embodiment provides a method for controlling the drilling trajectory of a horizontal well in a target oil layer with a dip angle of 0°. The method is specifically as follows:

[0073] According to the geological interpretation of the seismic profile of the target oil layer, when it is inferred that the oil layer dip angle of the target oil layer is 0°, the drilling tool assembly and the gamma logging equipment installed at the rear end of the drill bit are lowered to control the drill bit to drill into the rock formation, and the value of the upper gamma curve is determined. When the range is 75API-200API and the value range of the lower gamma curve is 45API-74API, it can be judged that the drill bit is close to the target oil layer O. Further, when the value range of the upper gamma curve is 45API-74API, it can be judged that the drill bit drilled into the target oil layer O from point A1. According to the geological design plan and the design requirements of the ...

Embodiment 2

[0076] This embodiment provides a method for controlling the drilling trajectory of a horizontal well in a target oil layer with a dip angle of 2°. The method is specifically as follows:

[0077] According to the geological interpretation of the seismic profile of the target oil layer, when it is inferred that the oil layer dip angle of the target oil layer O is 2°, the drilling tool assembly and the gamma logging equipment arranged at the rear end of the drill bit are lowered, and the drill bit is controlled to drill into the rock formation, and wait for the upper gamma curve. When the value range is 75API-200API, and the value range of the lower gamma curve is 45API-74API, it can be judged that the drill bit is close to the target oil layer O. Further, when the value range of the upper gamma curve is 45API-74API, it can be judged that the drill bit drilled into the target oil layer O from point A2. According to the geological design plan and the design requirements of the bo...

Embodiment 3

[0080] This embodiment provides a method for controlling the drilling trajectory of a horizontal well in a target oil layer with a dip angle of -2°. The method is specifically as follows:

[0081]According to the geological interpretation of the seismic profile of the target oil layer, when it is inferred that the oil layer dip of the target oil layer is -2°, the drilling tool assembly and the gamma logging equipment installed at the rear end of the drill bit are lowered, and the drill bit is controlled to drill into the rock formation. When the value range is 75API-200API and the value range of the lower gamma curve is 45API-74API, it can be judged that the drill bit is close to the target oil layer O. Further, when the value range of the upper gamma curve is 45API-74API, it can be judged that the drill bit drilled into the target oil layer O from point A3. According to the geological design plan and the design requirements of the borehole trajectory, as well as the change an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com