Subway station prefabricated rail top air duct and installation mode thereof

A technology for rail top air ducts and subway stations, which is applied in earth square drilling, mine/tunnel ventilation, mining equipment, etc. It can solve problems such as difficult pouring, high maintenance costs, and unguaranteed airtightness, and achieves convenience. Transportation and hoisting, saving frame links, avoiding perishable and perishable effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

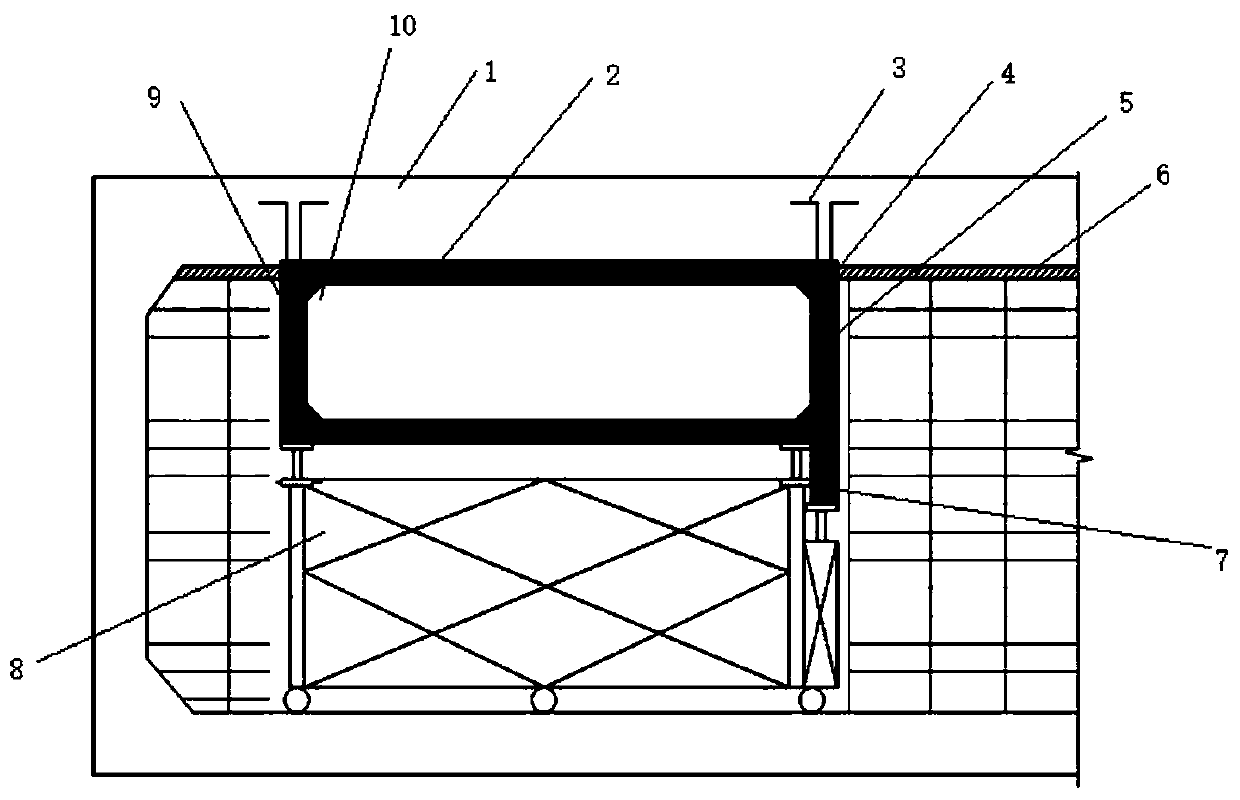

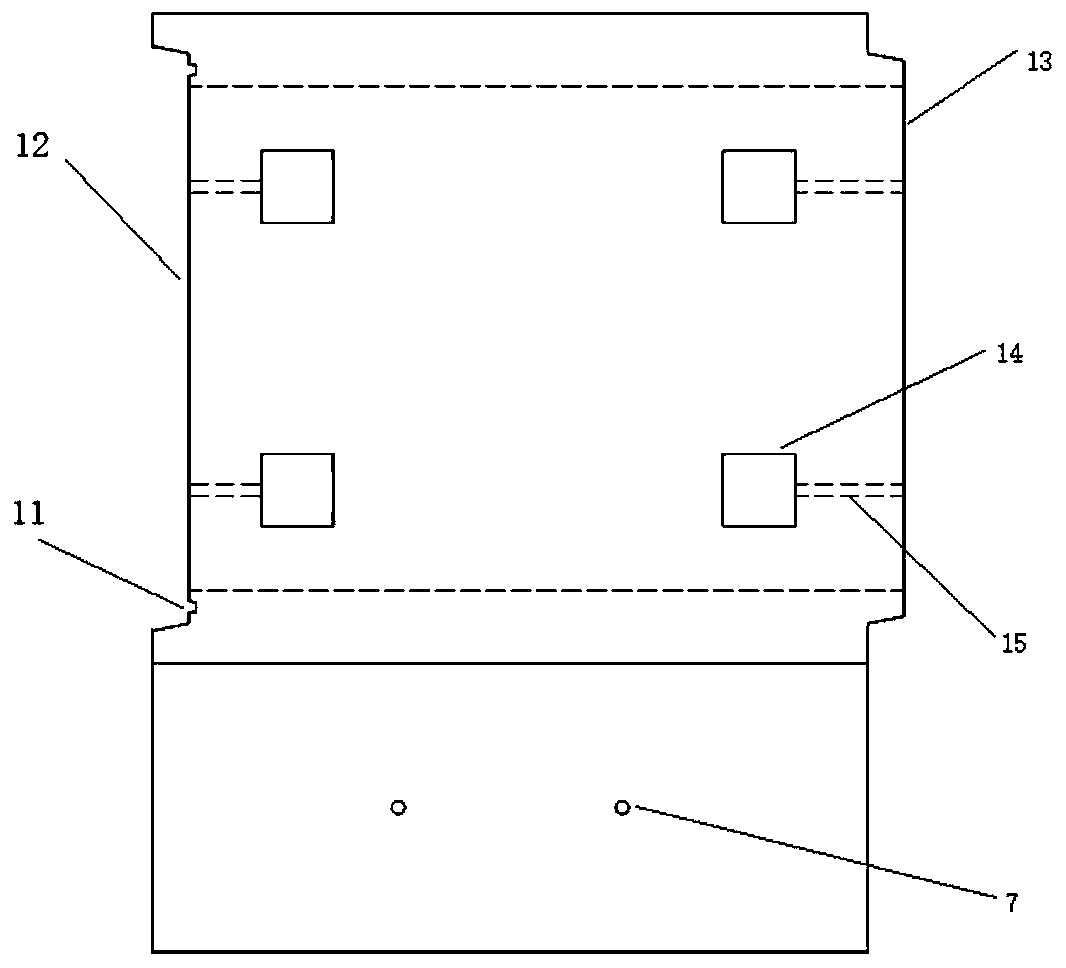

[0058] Such as figure 1 , figure 2 As shown, the lower end of the right air duct wall 5 is provided with a reserved hole 7, and two of the reserved holes 7 are arranged on the same horizontal line for installing the subway screen door. In the prior art, after pouring or installation of the rail-top air duct, when the screen door needs to be installed, holes are directly drilled on site, which is difficult to operate and easily destroys the stability of the installed structure.

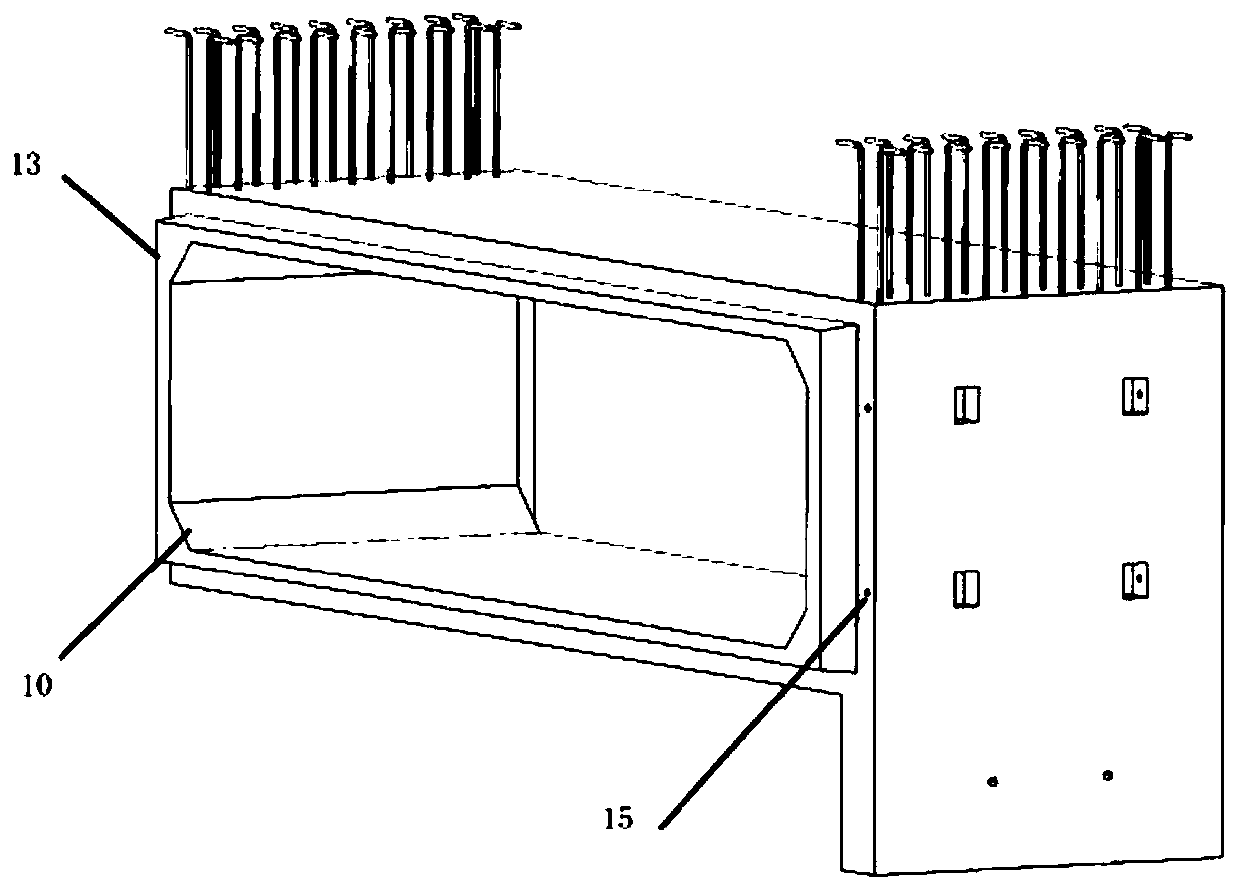

[0059] combine figure 2 , image 3 , Figure 4 It can be seen that the two ports of the left and right air duct walls are respectively provided with screw holes 15, and the outer surfaces of the left and right air duct walls are provided with hand holes 14, and the bolts can be put into the screw holes 15 through the hand holes 14 , the hand hole 14 is located about 15cm away from the port of the prefabricated rail top air duct, when the prefabricated rail top air ducts are connected to each othe...

Embodiment 2

[0075] Such as figure 1 , Figure 6 As shown, the lower end of the right air duct wall 5 is provided with a reserved hole 7, and two of the reserved holes 7 are arranged on the same horizontal line for installing the subway screen door. The reserved hole 7 is 190mm away from the lower end of the right air duct wall 5, and has a diameter of 20mm. In the prior art, after pouring or installation of the rail-top air duct, when the screen door needs to be installed, holes are directly drilled on site, which is difficult to operate and easily destroys the stability of the installed structure.

[0076] Such as Figure 6 , Figure 7 As shown, the ports on both sides of the left and right air duct walls are respectively provided with screw holes 15, and the outer surfaces of the left and right air duct walls are provided with hand holes 14, and the bolts can be put into the screw holes 15 through the hand holes 14. middle. Further, the hand hole 14 is composed of a pre-embedded st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com