A gas-liquid separation constant pressure oil tank and its control method

A technology of gas-liquid separation and pressure oil tank, which is applied in the direction of oil supply oil tank device, fluid pressure actuation device, fluid pressure actuation system components, etc. It can solve problems such as pressure fluctuations, achieve increased circulation, prevent oxidation and cavitation, The effect of improving the ability to adapt to complex environments and complex working conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Below in conjunction with embodiment the present invention is described in further detail:

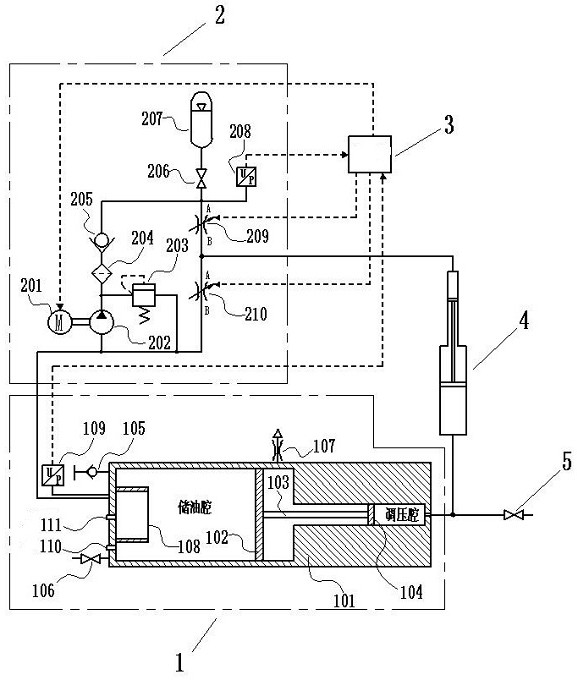

[0030] Such as figure 1 As shown, a gas-liquid separation constant pressure oil tank includes a fuel tank body 1 and a pressure regulation system that actively adjusts oil pressure fluctuations inside the oil tank body 1, and the pressure regulation system includes a pressure regulation system for regulating oil pressure 2. The controller 3 that controls the pressure regulation system 2 and the supercharger 4 that connects the fuel tank body 1 and the pressure regulation system 2 to transmit pressure regulation. The supercharger 4 includes a high-pressure chamber and a low-pressure chamber, and the high-pressure chamber and the low-pressure chamber They are respectively connected with the pressure regulating system 2 and the fuel tank body 1 . The invention can actively adjust the oil pressure fluctuation inside the oil tank body through the pressure regulating system, has the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com