Energy-saving and efficient explosive filling method and structure in blast construction

A technology of explosives during construction, applied in blasting and other directions, which can solve the problems of inconvenient and precise control of the placement position, improve work efficiency, and long waiting time, and achieve the effects of reducing the unit consumption of explosives, uniform axial blasting pressure, and reducing the root cause

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

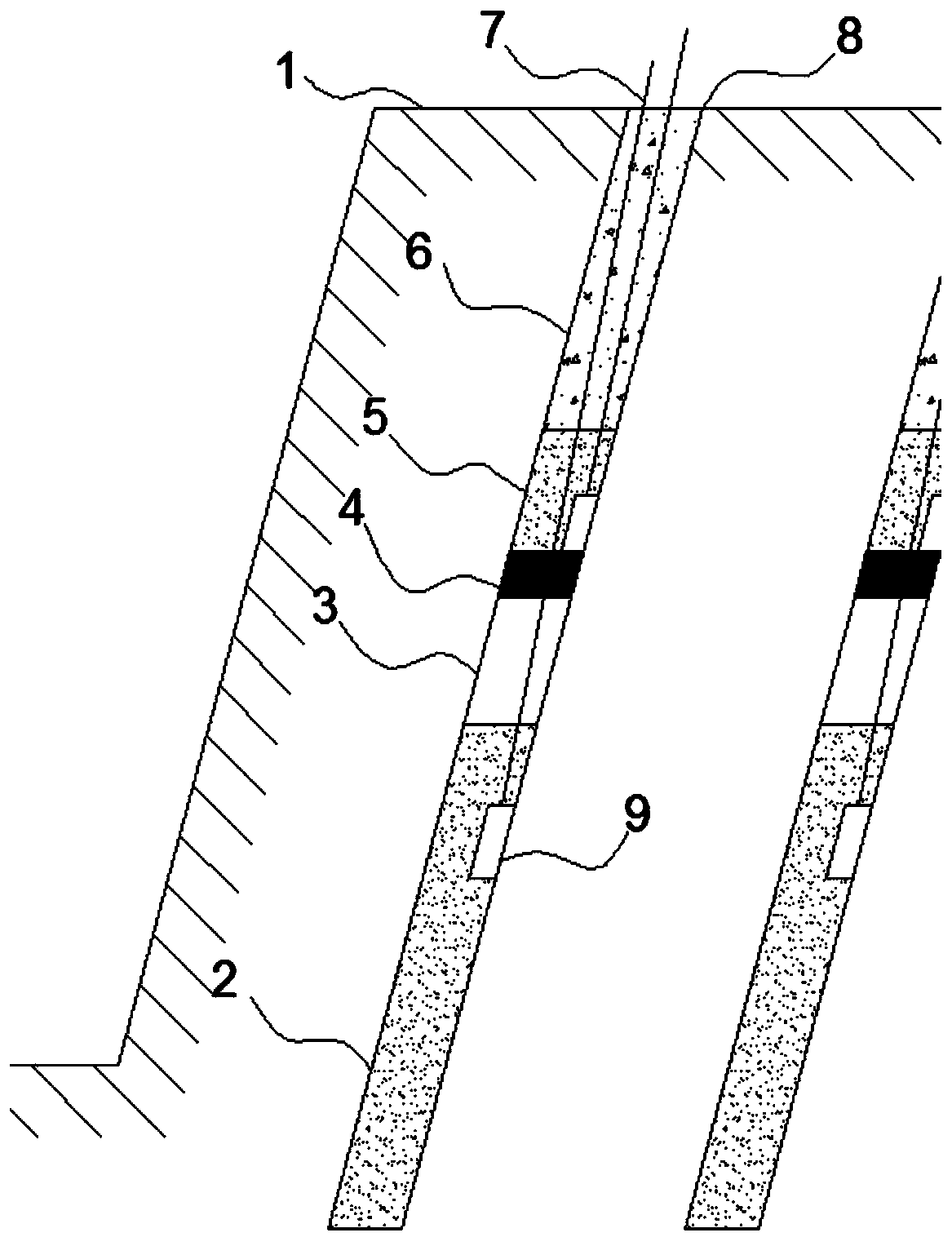

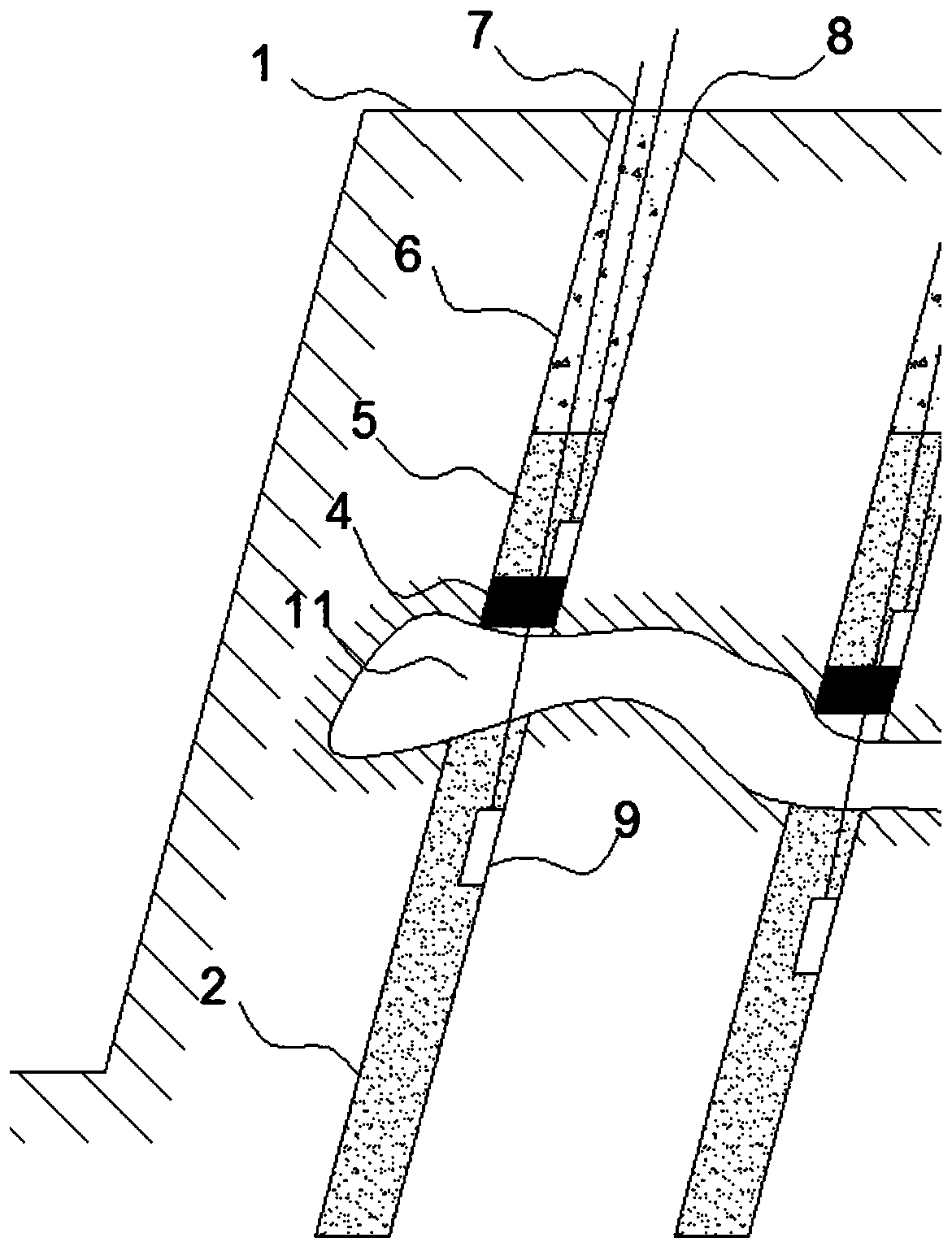

[0065] like figure 1 As shown, an energy-saving and high-efficiency explosive filling structure in blasting construction includes a blasthole 8 arranged on the working surface 1, and the blasthole 8 is sequentially provided with a first explosive layer 2 and an interval air layer from bottom to top. 3. Spacer 4, second explosive layer 5, plugging layer 6. The first explosive layer 2 and the second explosive layer 5 are all provided with a priming charge 9, and the priming charge 9 includes a strip emulsion explosive and a detonator 19, and the detonator 19 is installed in the strip emulsion explosive and connected There is a detonating tube 7; said detonating tube 7 extends to the working surface 1. like figure 2 When water accumulates at the bottom of the first explosive layer 2, the bottom must be an emulsion explosive, and the rest of the first explosive layer 2 and the second explosive layer 5 can be powdered explosives or emulsion explosives, preferably powdered explos...

Embodiment approach

[0094] Another way of implementation: such as Figure 15 , 16 As shown in and 17, the determination of the position and height of the hole area 11 can also be carried out by the second hole detection device 28, and the second hole detection device 26 includes a first wooden bar 29 and a second wooden bar whose upper ends are hinged together 30, the first wooden bar 29 is provided with a plug 2902, and the second wooden bar 30 is provided with a socket 3001, and the plug 2902 and the socket 3001 cooperate with each other to form an insertion connection. Make the first wooden strip 29 and the second wooden strip 30 owing to form plug joint, there is certain frictional force between the plug 2902 and the jack 3001, can guarantee that when the second hole detecting device 28 is hung down in the blasthole 8, the first The wooden strip 29 and the second wooden strip 30 will not be separated easily, so as to avoid being stuck by the inner wall of the blasthole 8, so as to ensure the...

Embodiment 2

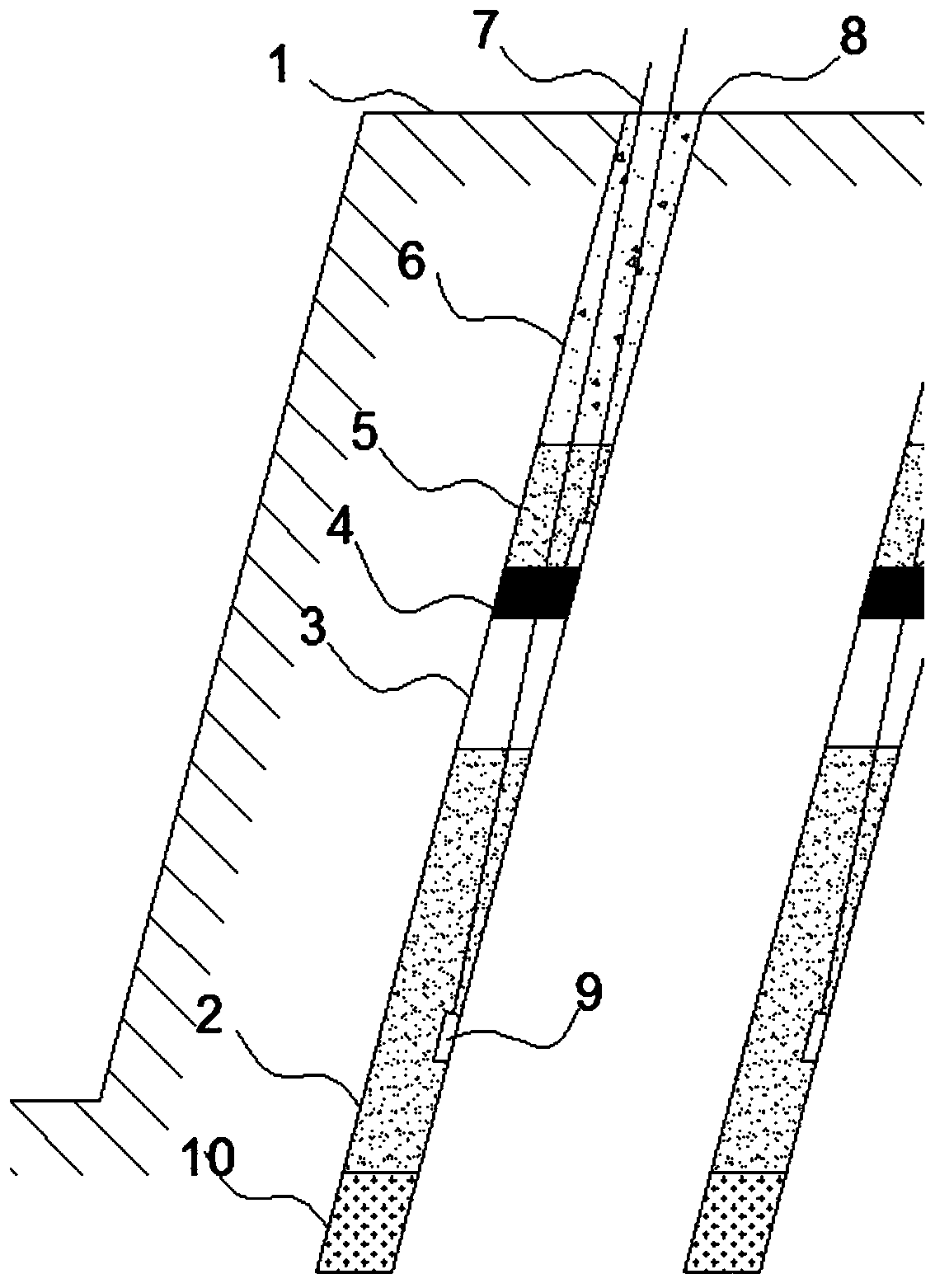

[0108] like figure 2 Shown is the preferred embodiment 2 of the present invention, specifically the embodiment when there is a lot of water at the bottom of the blast hole.

[0109] The explosive filling structure of this embodiment is consistent with that of Embodiment 1, except that the bottom of the first explosive layer 2 is an emulsion explosive layer 10 .

[0110] This embodiment is consistent with the explosive filling method of Example 1, except that when filling the first explosive layer 2, a corresponding amount of emulsion explosive is filled at the bottom according to the height of the accumulated water, so that the emulsion explosive layer 10 is higher than the accumulated water. The emulsion explosive layer 10 uses the emulsion explosive packaged in plastic bags. The emulsion explosive packaged in plastic bags has good waterproof performance and can effectively avoid operational accidents where the explosives fail due to accumulated water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com