Customizable broadband efficient ventilation sound absorber finite element simulation and demonstration verification method

A verification method and sound absorber technology, applied in design optimization/simulation, calculation, computer-aided design, etc., can solve problems such as the reduction of absorption rate, achieve the effect of overcoming technical bottlenecks and realizing customization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below by embodiment and in conjunction with accompanying drawing, the present invention will be further described:

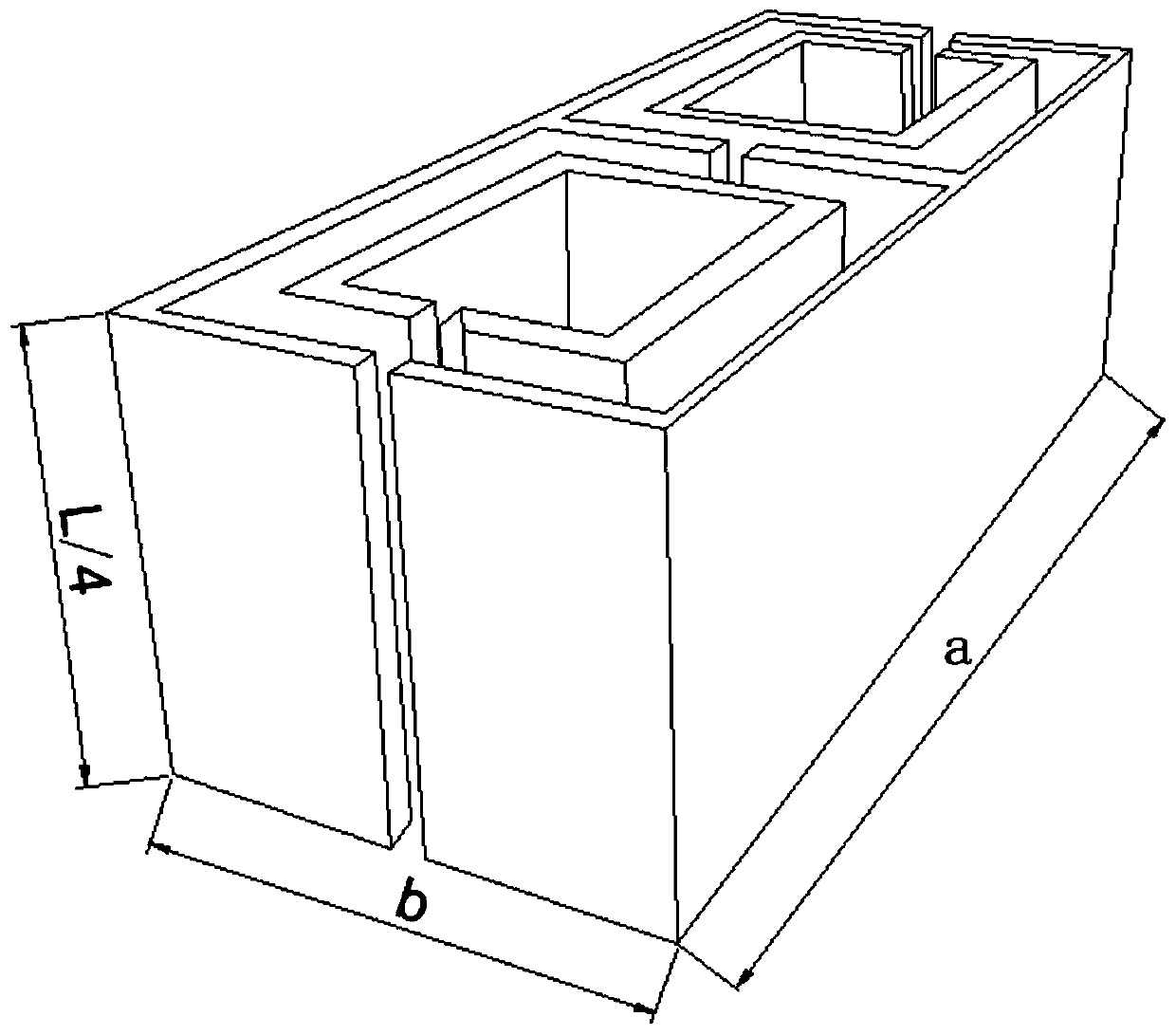

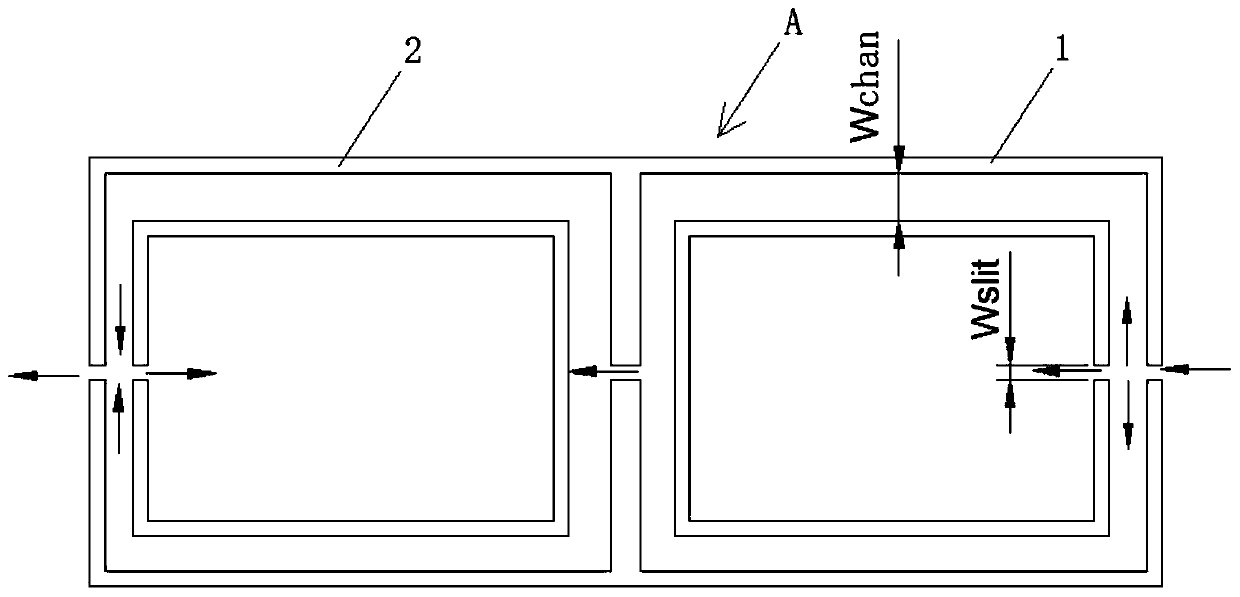

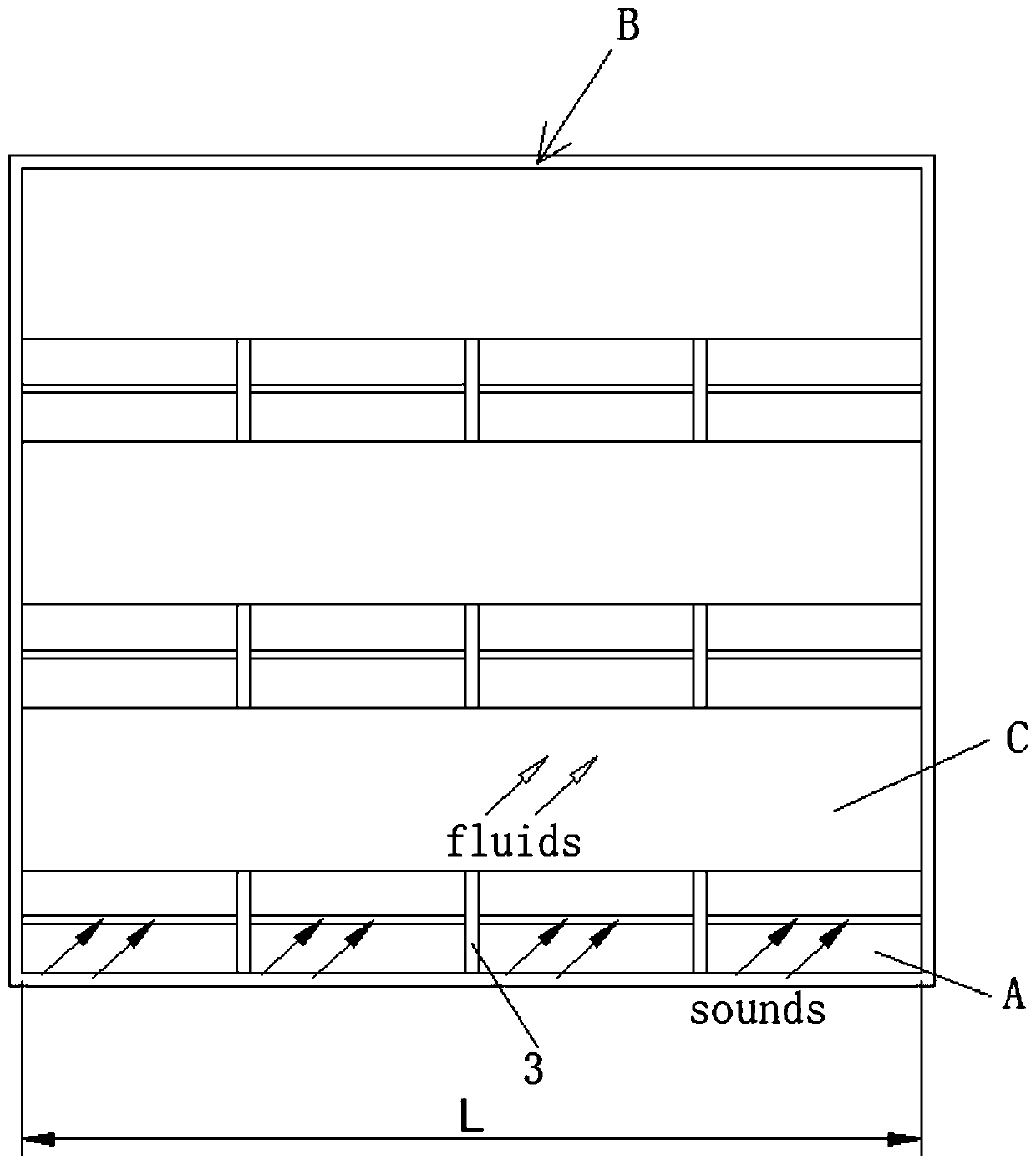

[0031] combine figure 1 , figure 2 As shown, a high-efficiency ventilation and sound absorber is composed of two first split tube resonant cavities 1 and second split tube resonant cavities 2 arranged side by side symmetrically. Each split tube resonator 1 is composed of an inner frame and an outer frame, and the whole is in the shape of "Hui". The left and right sides of the first split tube resonant cavity 1 and the second split tube resonant cavity 2 are equipped with cover plates (not shown in the figure), so as to form sound-absorbing channels between the inner and outer frames.

[0032] In the middle part of the front side wall of the outer frame, the middle part of the front side wall of the inner frame, and the middle part of the rear side wall of the outer frame of the first split tube resonant cavity 1, in the middle part of the front side wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Elastic modulus | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap