Ultraviolet LED packaging structure

A technology of LED packaging and ultraviolet light, applied in electrical components, circuits, semiconductor devices, etc., can solve the problems of high cost and complex process of ultraviolet light emitting diodes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

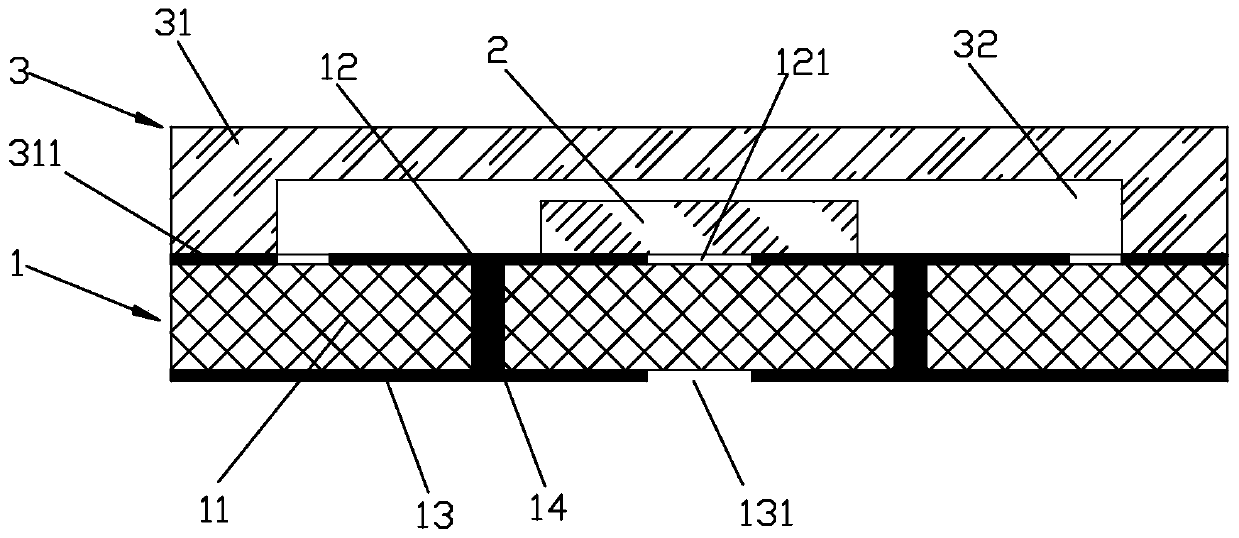

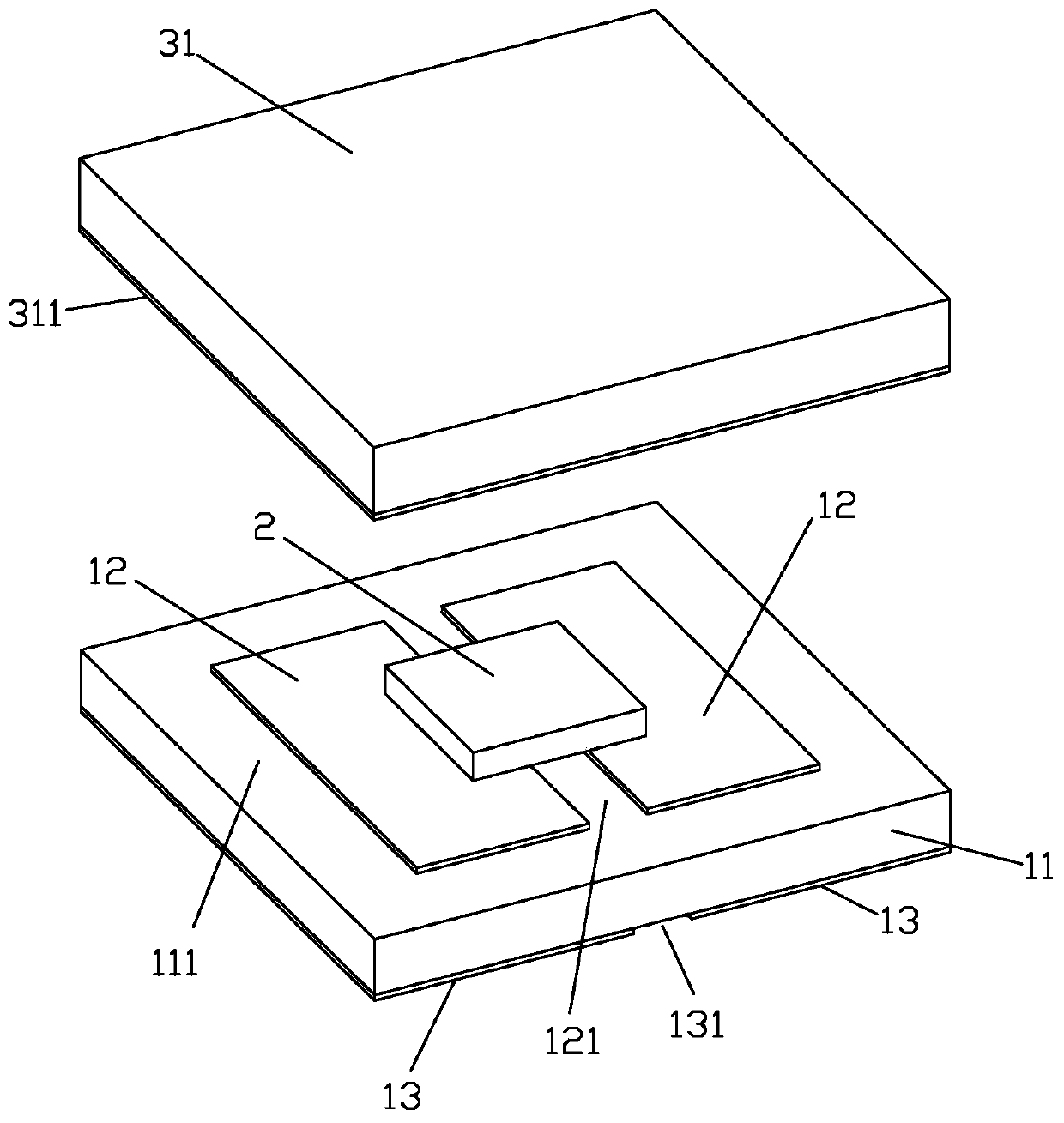

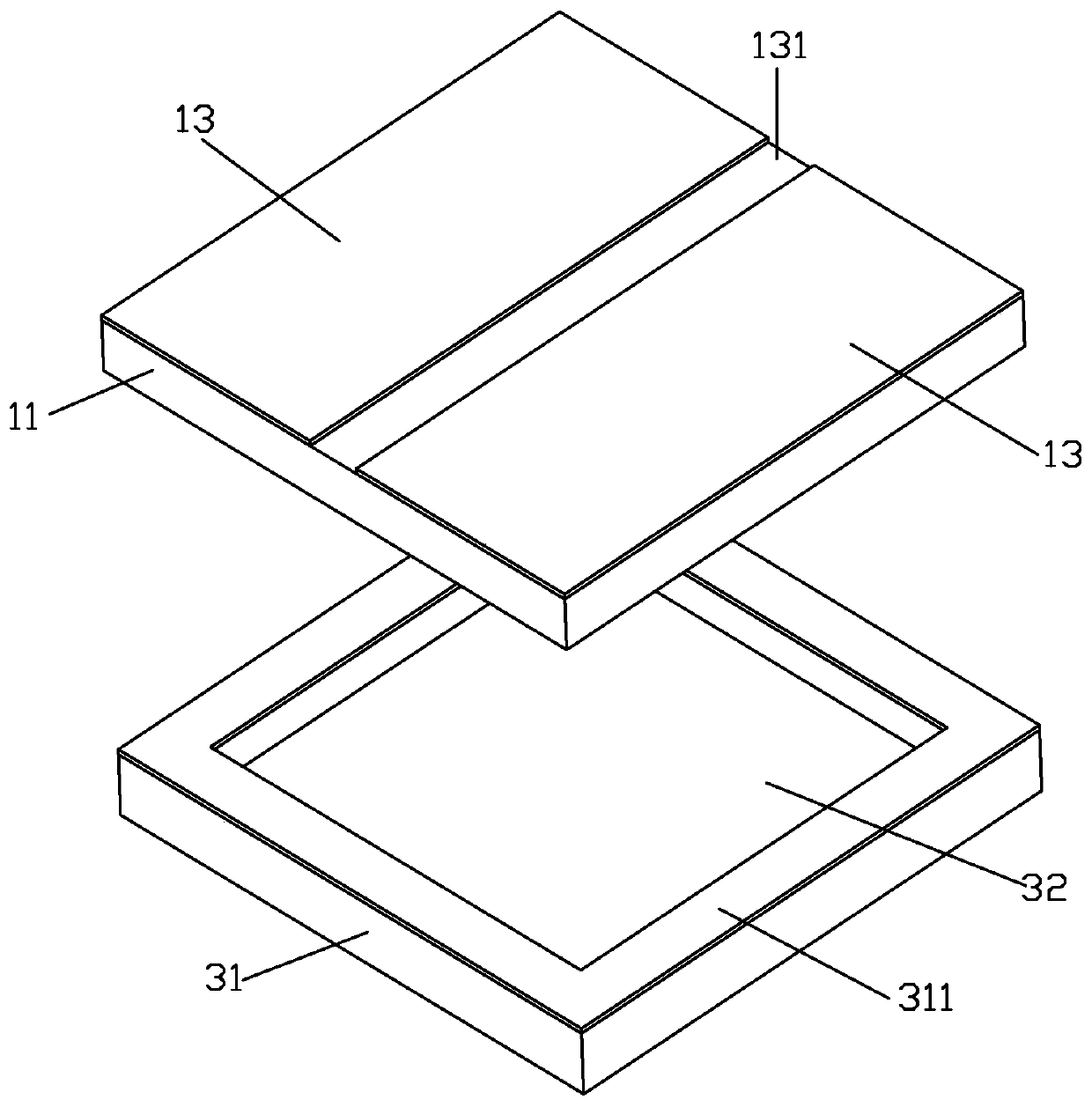

[0025] Please check Figure 1 to Figure 3 , UV LED packaging structure, including base 1, UV LED chip 2 and window 3.

[0026] The base 1 includes a substrate 11, such as a silicon-based material or a ceramic material, the top surface of the substrate 11 is provided with a top metal layer 12, the bottom surface of the substrate 11 is provided with a bottom metal layer 13, and the substrate 11 is provided with a through hole penetrating the top and bottom, and a conductive body 14 is additionally provided. The conductive body 14 is located in the through hole. The conductive body 14 is fixed and electrically connected to the top and bottom metal layers 12 and 13 to form a whole. In this embodiment: the top surface of the substrate 11 is provided with two top metal layers 12 spaced apart, an upper space 121 is formed between the two top metal layers 12, and the top surface of the substrate 11 is The Japanese-shaped area covered by the metal layer 12 (the two top metal layers 12 ar...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com