Plastic syringe recycling and processing device

A technology for recycling and injection needles, applied in hypodermic injection equipment, packaging, needles, etc., can solve the problems of waste of plastic resources, danger of professionals, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below with reference to the accompanying drawings and embodiments, and the mode of the present invention includes but not limited to the following embodiments.

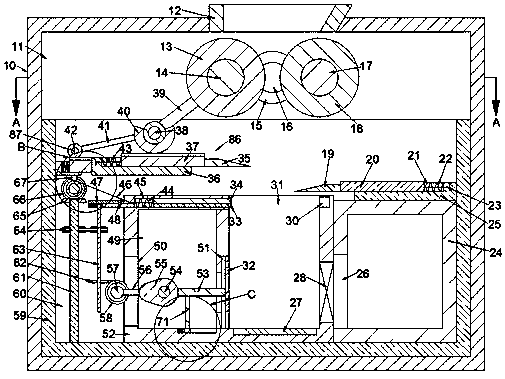

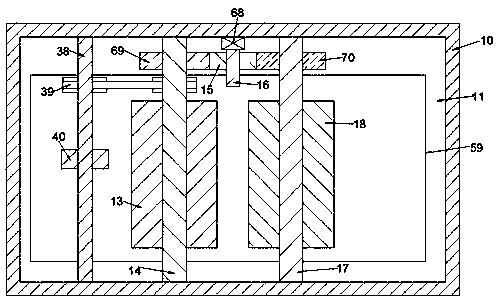

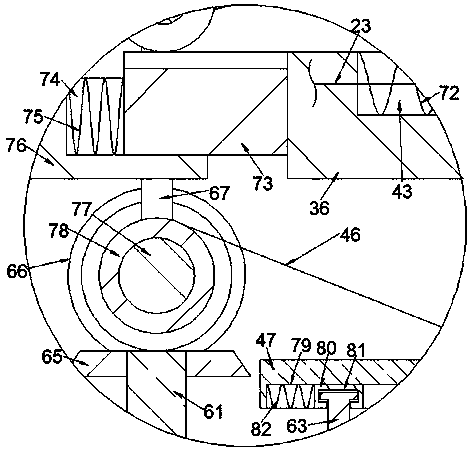

[0022] Such as Figure 1-4 As shown, a plastic injection syringe recovery processing device includes a working box 10 and a working cavity 11 located in the working box 10, the upper end wall of the working box 10 is provided with a feed port 12, and the working cavity 11 The front and rear chamber walls are rotated and provided with a first rotating shaft 14 located on the lower side of the feed port 12, and the first extrusion barrel 13 is fixed on the first rotating shaft 14, and the front and rear chamber walls of the working chamber 11 are rotated. The second rotating shaft 17 on the right side of the first rotating shaft 14, the second extruding barrel 18 is fixed on the second rotating shaft 17, the bottom wall of the working chamber 11 is fixed with an asse...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com