Autogenous mill stubborn stone bypass high-pressure roller grinding process

A high-pressure roller mill and autogenous mill technology, applied in the direction of solid separation, filter screen, grid, etc., can solve the problems of low work efficiency and difficult stone treatment, so as to improve processing efficiency, improve screening ability, and avoid clogging. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

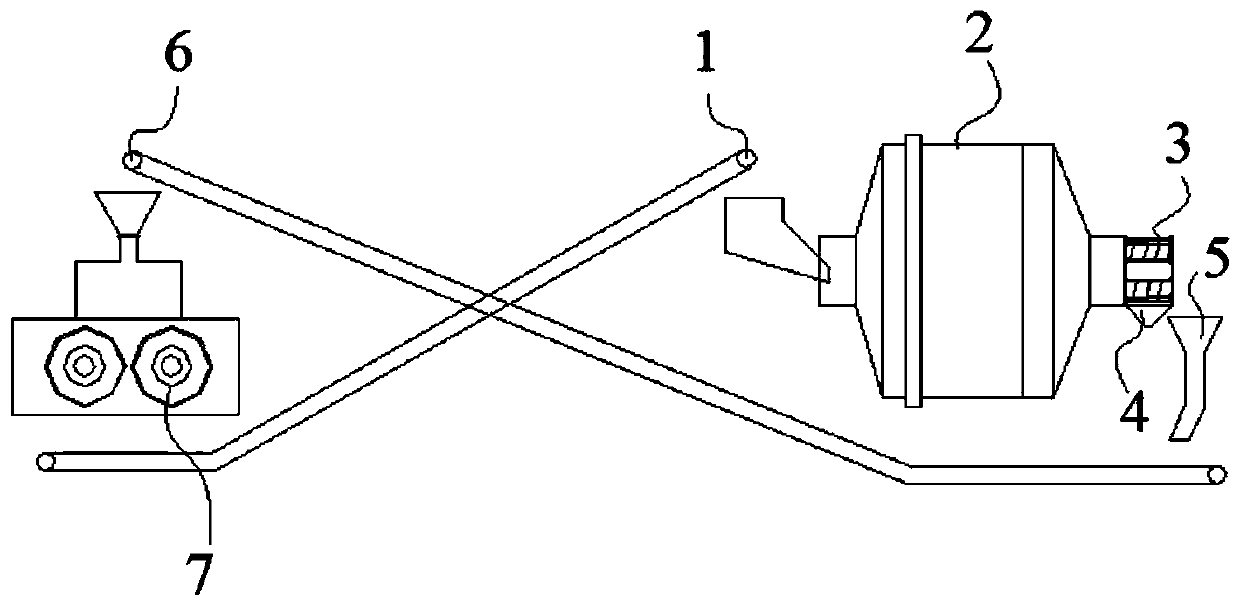

[0037] A kind of autogenous mill stubborn stone bypass high-pressure roller mill process of the present embodiment uses a high-pressure roller mill system, such as figure 1 As shown, the high-pressure roller mill system includes a feed conveyor belt 1, an autogenous mill 2, and a sieve hopper 4, and is characterized in that: it also includes a cylinder sieve 3, a sieve hopper 5, a return conveyor belt 6 and a crushing Device 7, the end of described feed conveyer belt 1 is positioned at above the feed inlet of autogenous mill 2; An upper screen funnel 4 is arranged directly below, and an under-screen funnel 5 is arranged below the discharge end of the cylindrical sieve 3; the head end of the return conveyor belt 6 is located below the under-screen funnel 5, and The end is located above the feed inlet of the crushing device 7, and its process steps are as follows:

[0038] Step 1. The ore discharge product of the autogenous mill 2 enters the cylinder screen 3: the cylinder scre...

Embodiment 2

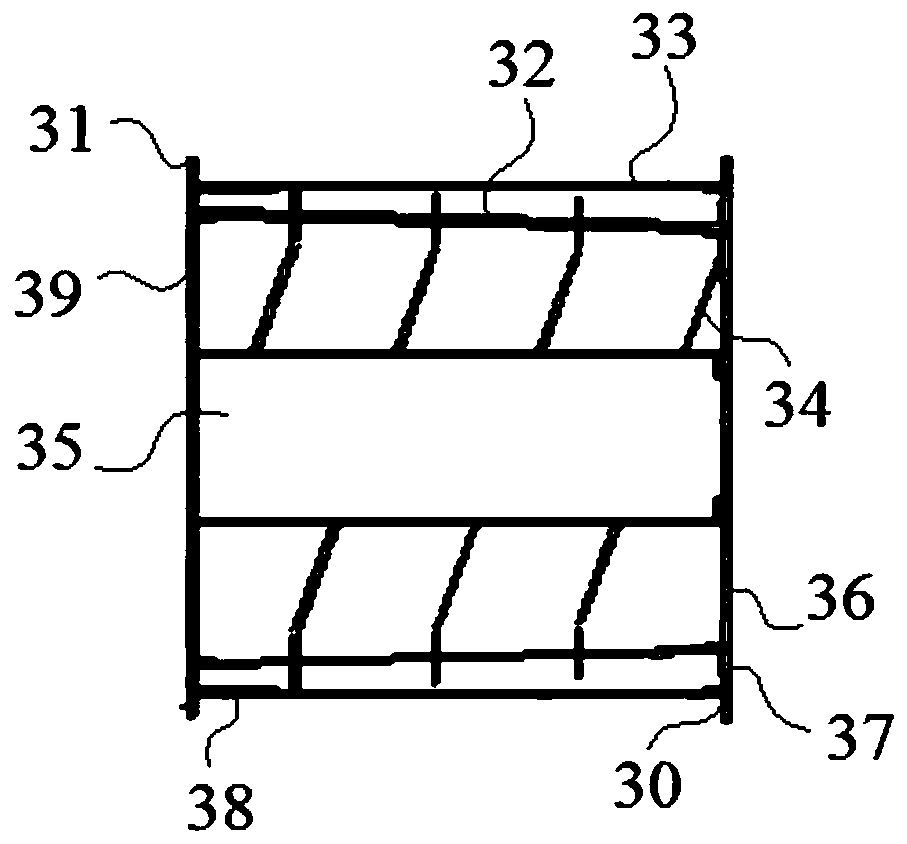

[0042] A kind of autogenous mill stubborn stone bypass high-pressure roller mill process of the present embodiment, its basic structure of the high-pressure roller mill system used is the same as that of embodiment 1, the differences and improvements are as follows: figure 2 As shown, the cylindrical sieve 3 includes a connecting plate 31, a first-stage sieve 32, a second-stage sieve 33, a supporting cylinder 35, a first-stage sieve discharge port 36, a second-stage sieve discharge port 37, a support ring 38, and a feed port 39 and the fixed plate 30, from the axis of the cylindrical screen 3 from the inside to the outside, followed by the support cylinder 35, the first stage sieve 32 and the second stage sieve 33, the support cylinder 35, the first stage sieve 32 and the second stage sieve 33 are located on the connecting plate 31 and the fixed plate 30, the feeding port 39 is located on the connecting plate 31, the opening of the feeding port 39 is located between the suppor...

Embodiment 3

[0044] In this embodiment, a kind of autogenous mill obstinate bypass high-pressure roller mill process, the basic structure of the high-pressure roller mill system used is the same as that of embodiment 2, the difference and improvement are: the first-stage sieve 32 and the second-stage sieve 33 All have sieve holes, and the sieve hole diameter on the second-stage sieve 33 is smaller than the sieve hole diameter on the first-stage sieve 32, and the sieve hole diameter of the second-stage sieve 33 is 3-8 mm, so that only the ore that is qualified to be ground can enter the lower sieve. One-stage treatment process; the hole diameter of the first-stage sieve 32 is 12-18mm, which ensures that larger ores and stubborn stones can pass through the cylindrical sieve 3, and prevents larger ores or stubborn stones from being blocked in the cylindrical sieve 3. Compared with Simple autogenous mill 2 grinding, the output of qualified ore in this embodiment has increased by 30%, and the co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap