Ultrasonic deviation rectification detection device with surface material and cooling sleeve of heat-proof lining structure

A detection device and ultrasonic technology, applied in the field of steel production lines, can solve the problems of easy deviation of strip steel, slowdown of production line, increase of failure rate, etc., and achieve the effects of convenient installation and cooling installation, convenient miniaturization, and noise reduction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

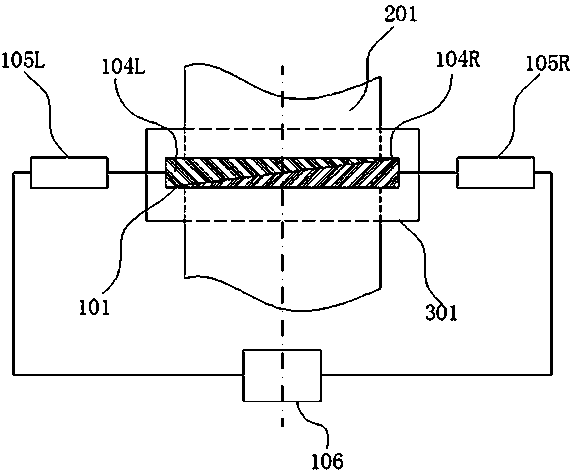

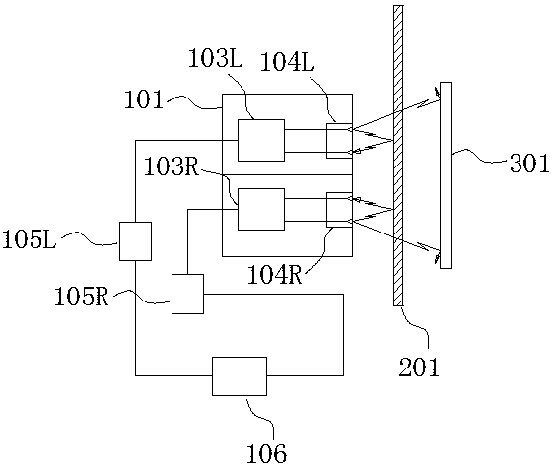

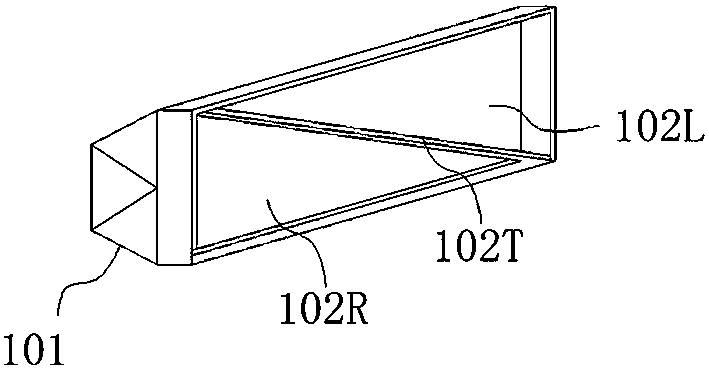

[0027] combine figure 1 Schematic diagram of the ultrasonic correction detection device. The strip steel 201 along the length direction passes through the ultrasonic detector 101 of the ultrasonic deviation correction detection device of the belt surface material, and the left ultrasonic pulse pulse signal processor 104L and the right ultrasonic pulse signal processor 104R of the ultrasonic deviation correction detection device form the reflection detection of ultrasonic waves, and detect the strip The left and right deviation of the steel, the left ultrasonic pulse signal processor 104L is connected with the left ultrasonic generator control circuit 105L, and the detected deviation is processed into an electrical signal and then fed back to the amplification and comparison processor 106 . The right ultrasonic pulse signal processor 104R is connected to the right ultrasonic generator control circuit 105R, and the detected deviation amount is processed into an electrical signal...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com