Three-dimensional paper bag making machine capable of achieving heat sealing

A bag making machine and paper bag technology, applied in bag making, paper making, paper/cardboard containers, etc., can solve the problems of inaccurate side edges of three-dimensional paper bags, unsuitable heating and sealing of paper bags, etc., achieve good market promotion prospects and realize automation The effect of control and convenience for fruit growers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

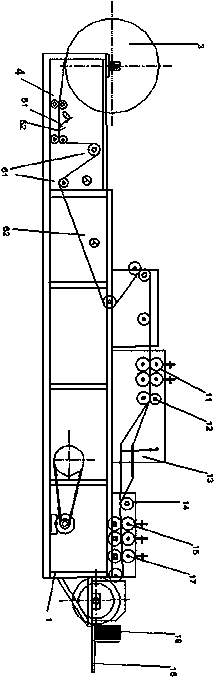

[0031] see figure 1 , a heat-sealable three-dimensional paper bag making machine, which includes a frame 1, one end of the frame is provided with an outer paper roll 2, and an outer paper roll 3 is set on the outer paper roll, and the outer paper roll The outer layer of paper on 3 is conveyed to the film application mechanism 5 under the guidance of several guide rollers 4, and the film application mechanism 5 is provided with a 10-15mm wide heat-sealing film 181 for sealing at the sealing position of each paper bag, The heat-sealing film 181 is a substance that is non-sticky at room temperature and viscous after heating, such as hot melt adhesive, plastic film, etc. The lower station is provided with a cooling mechanism 6 for cooling the heat-sealing film 181 to facilitate subsequent bag-making operations The lower station of the cooling mechanism 6 is provided with a cutting roller 11, and the cutting roller 11 is used to cut out a smooth opening 182 for the fruit handle to ...

Embodiment 2

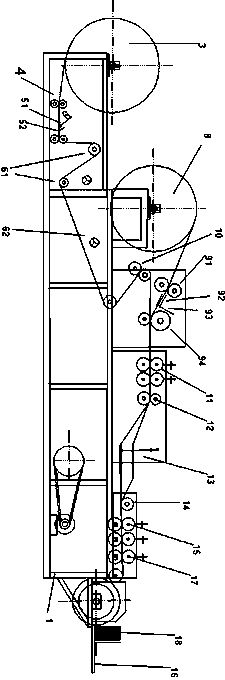

[0038] see figure 2, one end of the frame 1 located at the outer paper roll 2 is provided with an inner paper roll 7, the inner paper roll 7 is covered with an inner paper roll 8, and the frame 1 is provided with an inner and outer paper composite mechanism 9. It is used to transport the inner paper and the outer paper forward after overlapping.

[0039] The inner and outer paper composite mechanism 9 is located between the film applying mechanism 5 and the cutting roller 11, and includes at least one pair of drive rollers 91, guide plates 92, cutters 93 for cutting the inner paper and inner and outer paper composites arranged in sequence. Rollers 94, each pair of driving rollers 91 includes a driving roller and a driven roller, the axes of the driving roller and the driven roller are arranged parallel to each other, and the inner paper conveyed from the inner paper roller 7 is Pass between the driving roller and the driven roller, the driving roller rotates to drive the inn...

Embodiment 3

[0043] The inner and outer paper composite mechanism 9 is an inner and outer paper composite roller 94, and the inner and outer paper composite mechanism 9 is arranged on the upper station of the film applying mechanism 5, and the inner and outer paper composite mechanism 9 makes the inner paper and the outer paper continuously Composite together, the heat-sealing film is set on the inner paper.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com