Automatic control device for locomotive sand scattering

An automatic control device, a technology for locomotives, applied in the direction of locomotives, etc., can solve problems such as inability to effectively solve the problem of wheel idling, inability to provide sufficient friction force, and difficulty in achieving sand spreading results, and achieve easy implementation, improved stability and safety. , the effect of easy deployment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to facilitate those skilled in the art to understand the technical solution of this patent, the technical solution of this patent will be further described in the form of specific cases below.

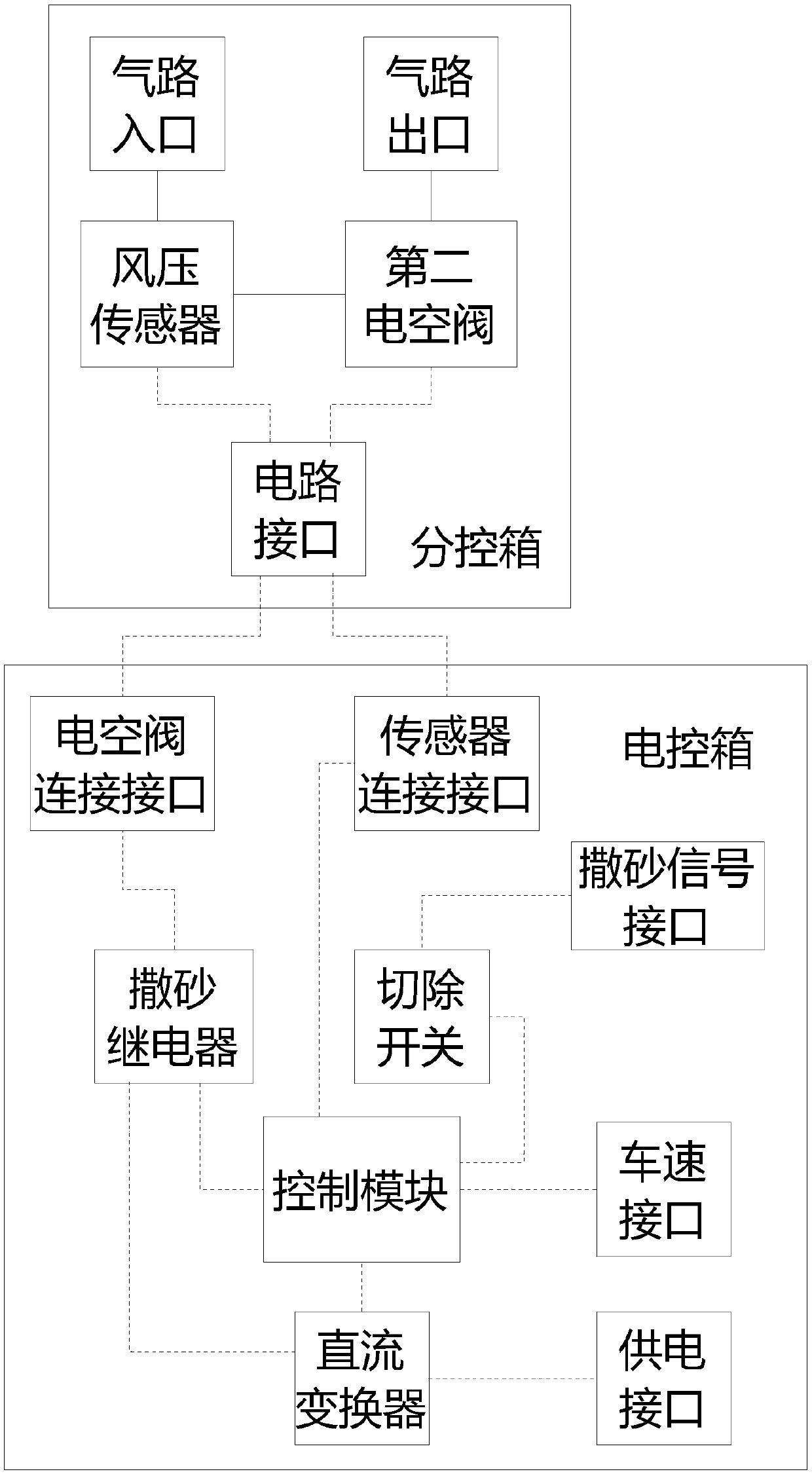

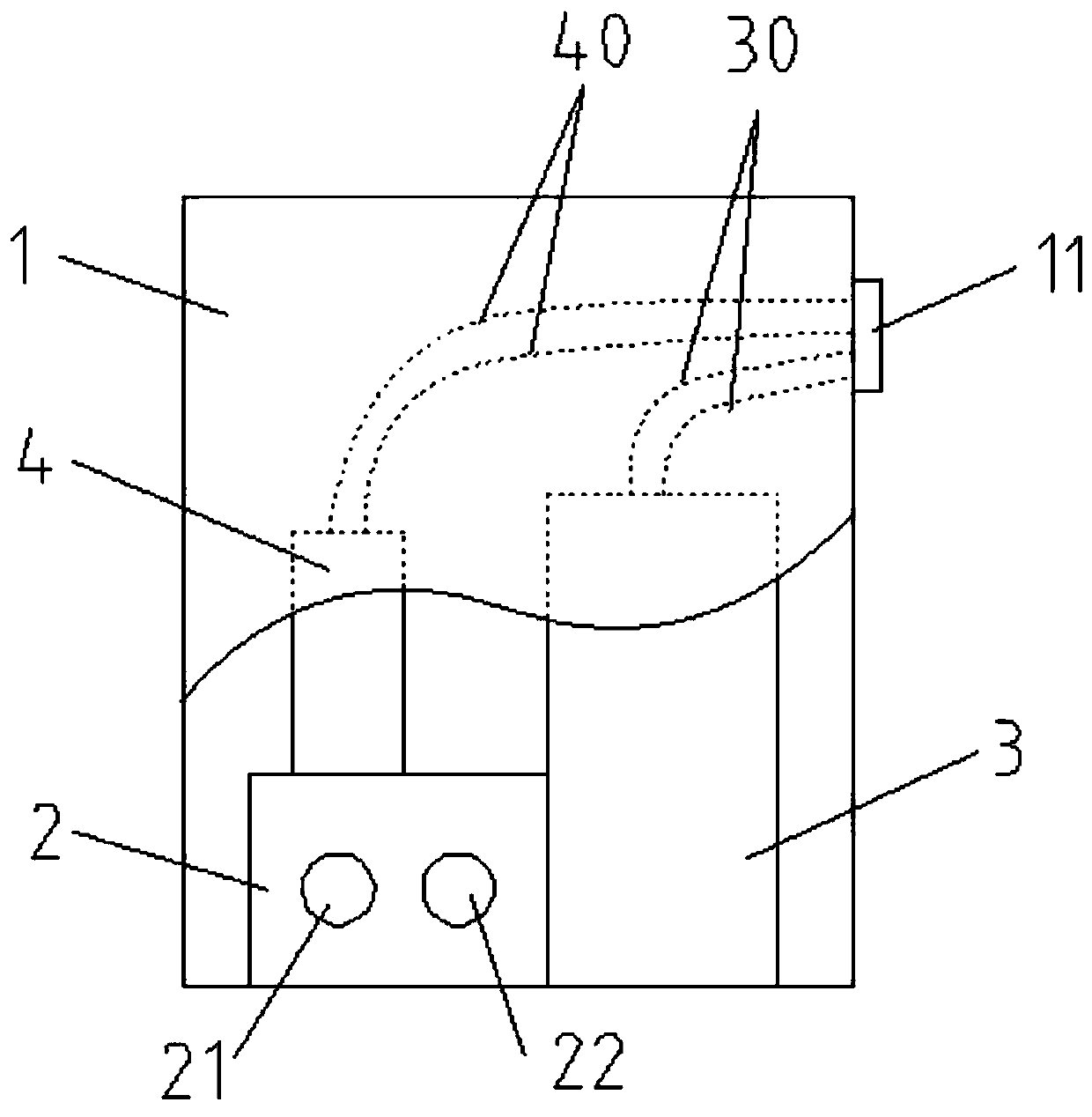

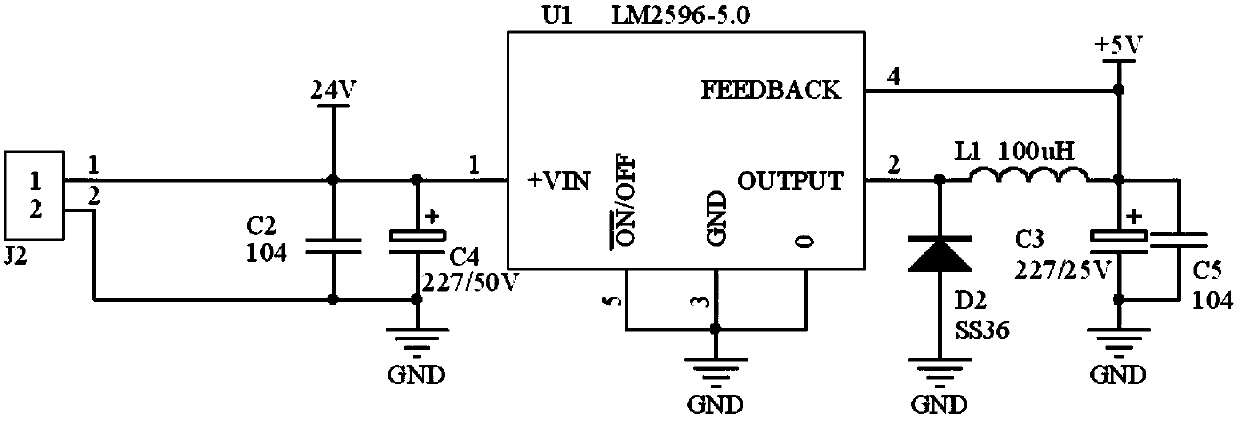

[0033] Such as figure 1 As shown, a locomotive sand spreading automatic control device includes an electric control box and a sub-control box, the sub-control box is provided with a wind pressure sensor and a sand-spraying electro-pneumatic valve, and the sub-control box has an air path inlet, The gas path outlet and the circuit interface, the sand spreading electropneumatic valve is connected between the gas path inlet and the gas path outlet, the wind pressure sensor is arranged between the gas path inlet and the sand spreading electropneumatic valve, the circuit interface It includes a sensor interface connected to the wind pressure sensor and an electropneumatic valve interface connected to the sand spreading electropneumatic valve, and the sand spreading electropne...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com