Papermaking method of multi-layer coated high-bulking high-whiteness matte coated paper

A technology of bulk and master paper, which is applied in the field of multi-layer coated high-bulk, high-brightness matt coated paper, which can solve the problems of inability to meet high-end printing, low whiteness, and large roughness, and achieve good printing results. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

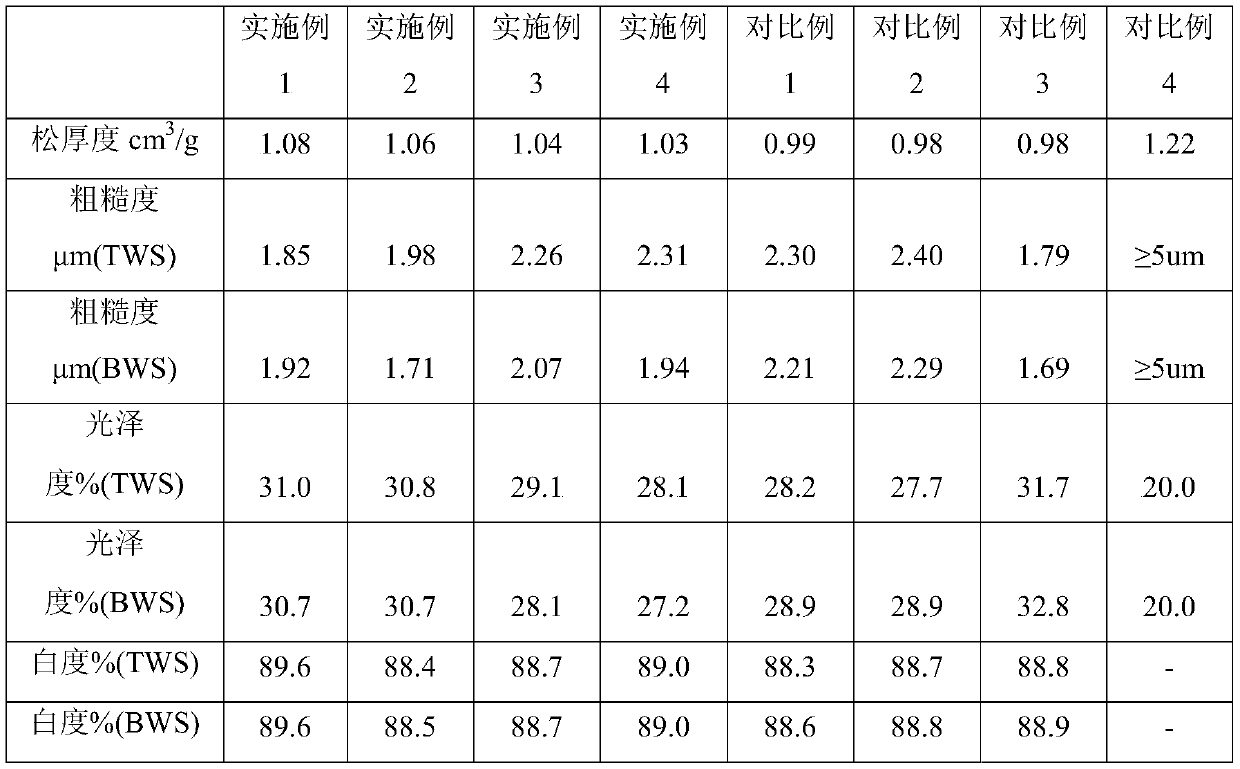

Examples

Embodiment 1

[0029] A method for making multi-layer coated high-bulk and high-whiteness matt art paper, comprising the following steps:

[0030] S1: Take kraft softwood pulp, bleached kraft hardwood pulp and alkaline hydrogen peroxide mechanical pulp, and mix them at a weight ratio of 20:55:25 to form a slurry mixture; after kraft softwood pulp is beaten, the freeness is 440ml, the bulk thickness is 1.3cm 3 / g; bleached kraft hardwood pulp has a freeness of 390ml and a bulk of 1.3cm after beating 3 / g; Alkaline hydrogen peroxide mechanical pulp has a freeness of 375ml and a bulk of 3.1cm after beating 3 / g, the whiteness is 79%;

[0031] S2: Add ground calcium carbonate and positive starch to the slurry mixture in step S1, and mix thoroughly to obtain base paper pulp; by weight ratio, the base paper pulp includes 93.7% of slurry mixture, 5.6% of ground calcium carbonate, and positive starch 0.7%; the ground calcium carbonate is the ground calcium carbonate C60 processed with polymer (po...

Embodiment 2

[0039] A method for making multi-layer coated high-bulk and high-whiteness matt art paper, comprising the following steps:

[0040] S1: Take kraft softwood pulp, bleached kraft hardwood pulp and alkaline hydrogen peroxide mechanical pulp, and mix them at a weight ratio of 20:55:25 to form a slurry mixture; after kraft softwood pulp is beaten, the freeness is 440ml, the bulk thickness is 1.3cm 3 / g; bleached kraft hardwood pulp has a freeness of 390ml and a bulk of 1.3cm after beating 3 / g; Alkaline hydrogen peroxide mechanical pulp has a freeness of 375ml and a bulk of 3.1cm after beating 3 / g, the whiteness is 79%;

[0041] S2: Add ground calcium carbonate and positive starch to the slurry mixture in step S1, and mix thoroughly to obtain base paper pulp; by weight ratio, the base paper pulp includes 93.7% of slurry mixture, 5.6% of ground calcium carbonate, and positive starch 0.7%; the ground calcium carbonate is the ground calcium carbonate C60 processed with polymer (po...

Embodiment 3

[0049] A method for making multi-layer coated high-bulk and high-whiteness matt art paper, comprising the following steps:

[0050] S1: Take kraft softwood pulp, bleached kraft hardwood pulp and alkaline hydrogen peroxide mechanical pulp, and mix them in a weight ratio of 28:40:32 to form a slurry mixture; the freeness of kraft softwood pulp after beating is 410ml, the bulk thickness is 1.2cm 3 / g; bleached kraft hardwood pulp has a freeness of 420ml and a bulk of 1.4cm after beating 3 / g; Alkaline hydrogen peroxide mechanical pulp has a freeness of 340ml and a bulk of 3.1cm after beating 3 / g, the whiteness is 80%;

[0051] S2: Add ground calcium carbonate and positive starch to the slurry mixture in step S1, and mix thoroughly to obtain base paper pulp; by weight ratio, the base paper pulp includes 97% of size mixture, 2% ground calcium carbonate, and positive starch 1%; the ground calcium carbonate is the ground calcium carbonate C60 processed with a polymer (polyacrylic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Freeness | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap