Cable trench expansion joint structure and construction method thereof

A technology of cable trenches and expansion joints, which is applied in the direction of cable installation, ground cable installation, and building components, etc. It can solve the problem of uneven settlement of cable trench expansion joint structures, inability to transmit force and coordinated deformation of cable structures, and differential settlement of expansion joint interfaces To achieve the effect of improving reliability and safety, improving stiffness and force transmission characteristics, and improving construction quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

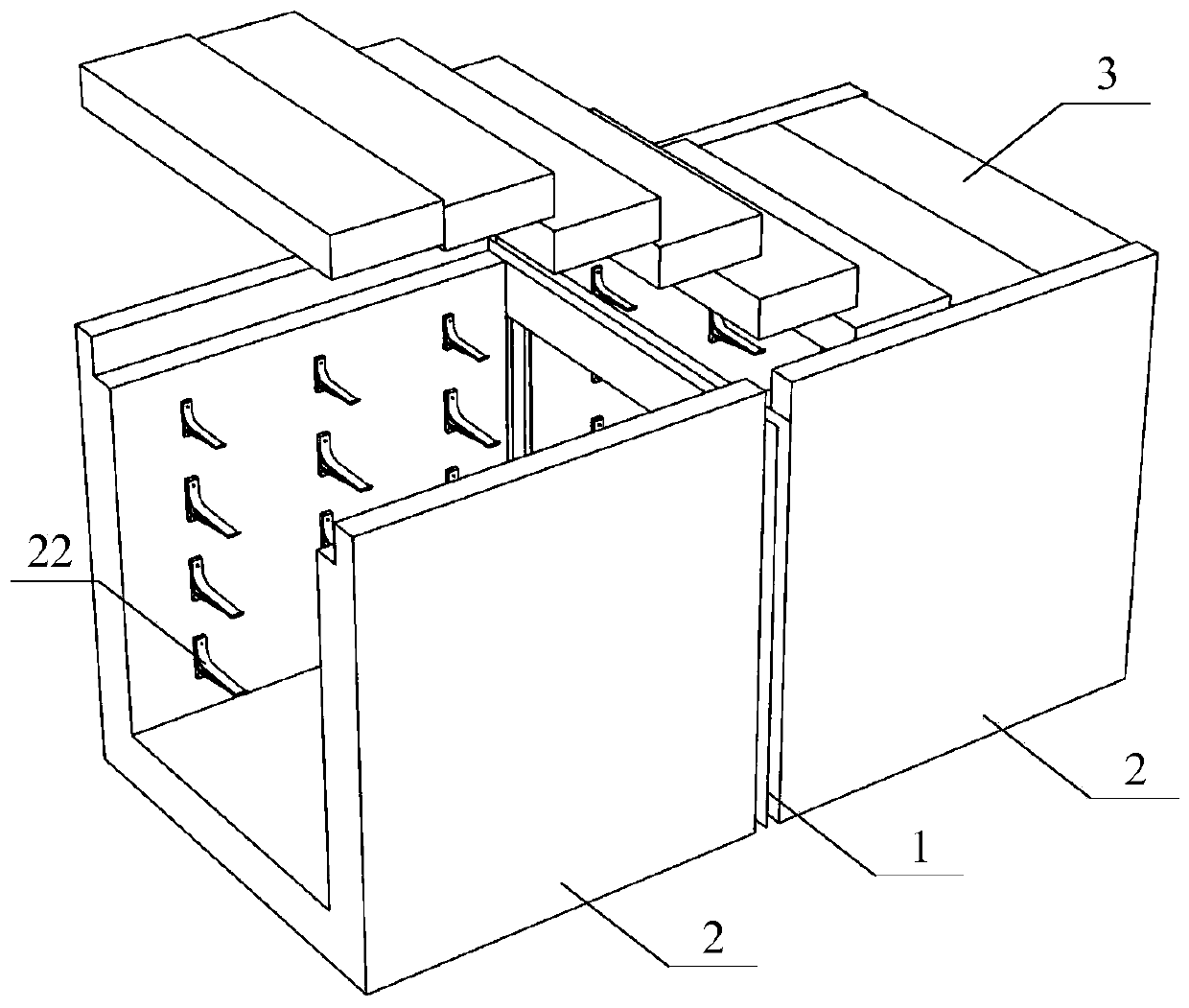

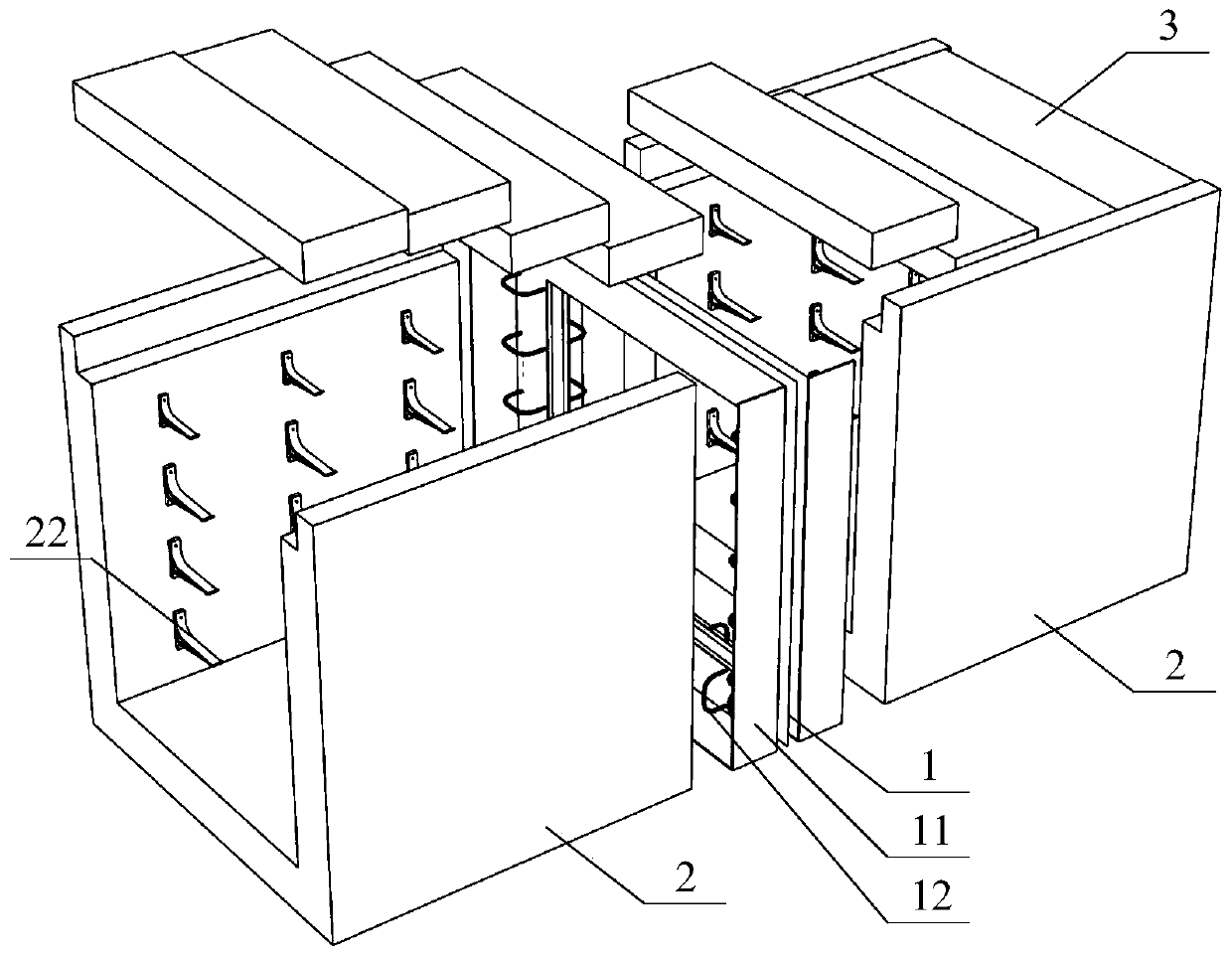

[0032] Such as Figure 1~2 As shown, it is a schematic diagram of the cable trench expansion joint structure of the present invention installed in the cable trench structure. The cable trench structure 2 is formed by pouring the steel cage after the steel bar 21 inside the cable trench structure is built, and then the cable trench structure 2 is installed. The cable brackets 22 on the side walls on both sides are used to place and limit the cables, and finally a prefabricated cable trench cover 3 is placed on the top of the cable trench structure 2 to form a closed space structure for protecting the cables.

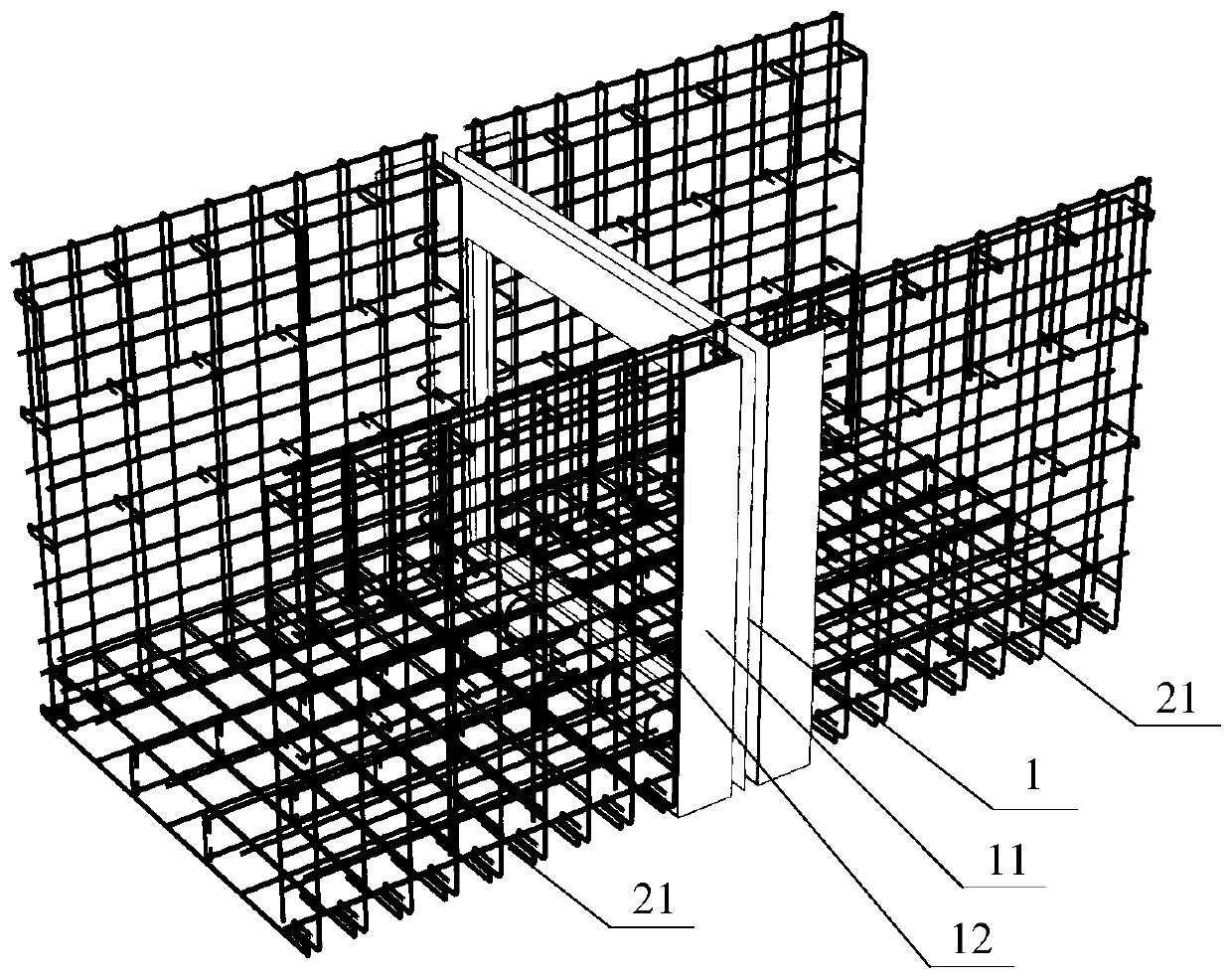

[0033] Such as Figure 3~4 As shown, there are several U-shaped overlapping steel bars 12 with appropriate spacing on both sides of the cable trench expansion joint structure, and the elastic section steel 1 of the expansion joint structure is connected to the internal steel bars 21 of the cable trench structure through the overlapping steel bars 12 during construction. ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Width | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com