Quick wall surface mounting structure and mounting method

An installation method and quick installation technology, applied in building construction, covering/lining, construction, etc., can solve the problems of complex leveling process, complicated installation steps, use of viscose, etc., and achieve simple leveling process and leveling effect. Good, easy to install

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

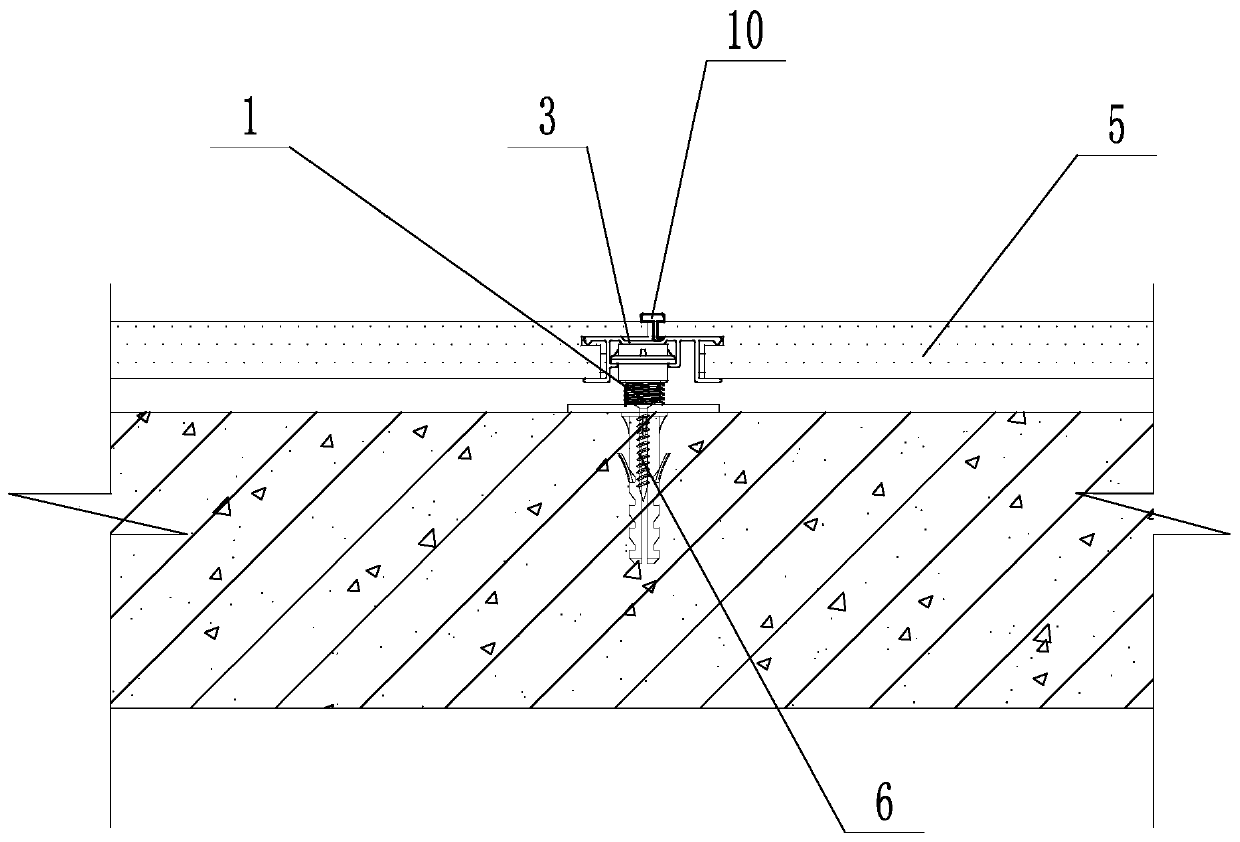

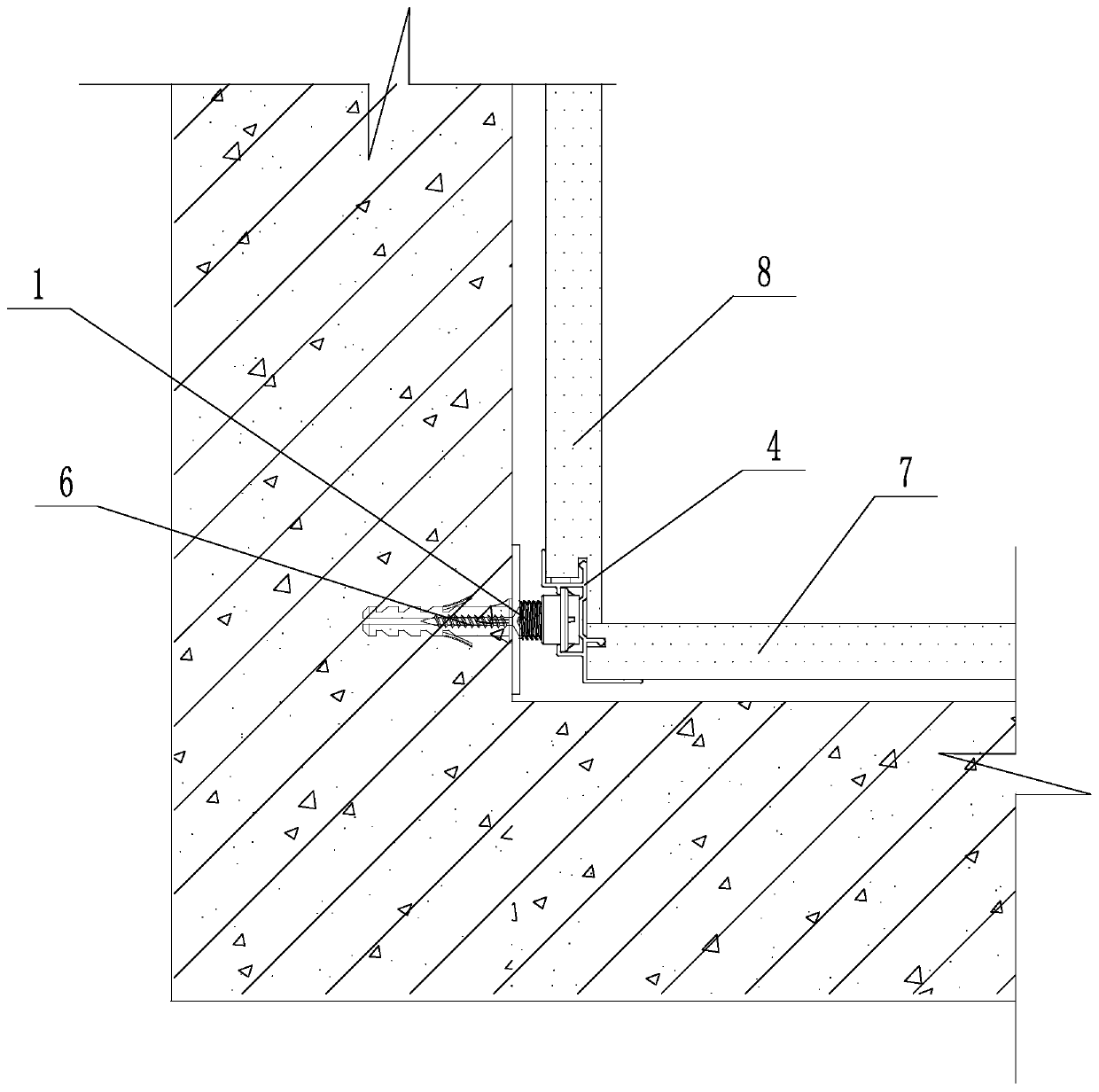

[0040] Such as figure 1 figure 2 and image 3 As shown, a fast-installed wall structure includes a decorative panel 5, a leveling assembly 1, a flat connector 3, and a female corner connector 4; the leveling assembly 1 includes an adjuster 1.2 and an adjustment foot for fixing to the wall 1.1, the adjustment foot 1.1 is threadedly connected with the regulator 1.2, and one end of the regulator 1.2 snaps into the flat connector 3 and can rotate relative to the flat connector 3, the flat connector 3 and the leveling component 1 form a flat component; one end of the regulator 1.2 snaps into the The 4 internal angle connections are capable of rotating relative to the internal angle connections 4, and the internal angle connection pieces 4 and the leveling assembly 1 form the internal angle assembly.

[0041] By implementing the above technical solution, all decorative panels 5 in the entire room can be completely installed, the installation process is simple, the connection is r...

Embodiment 2

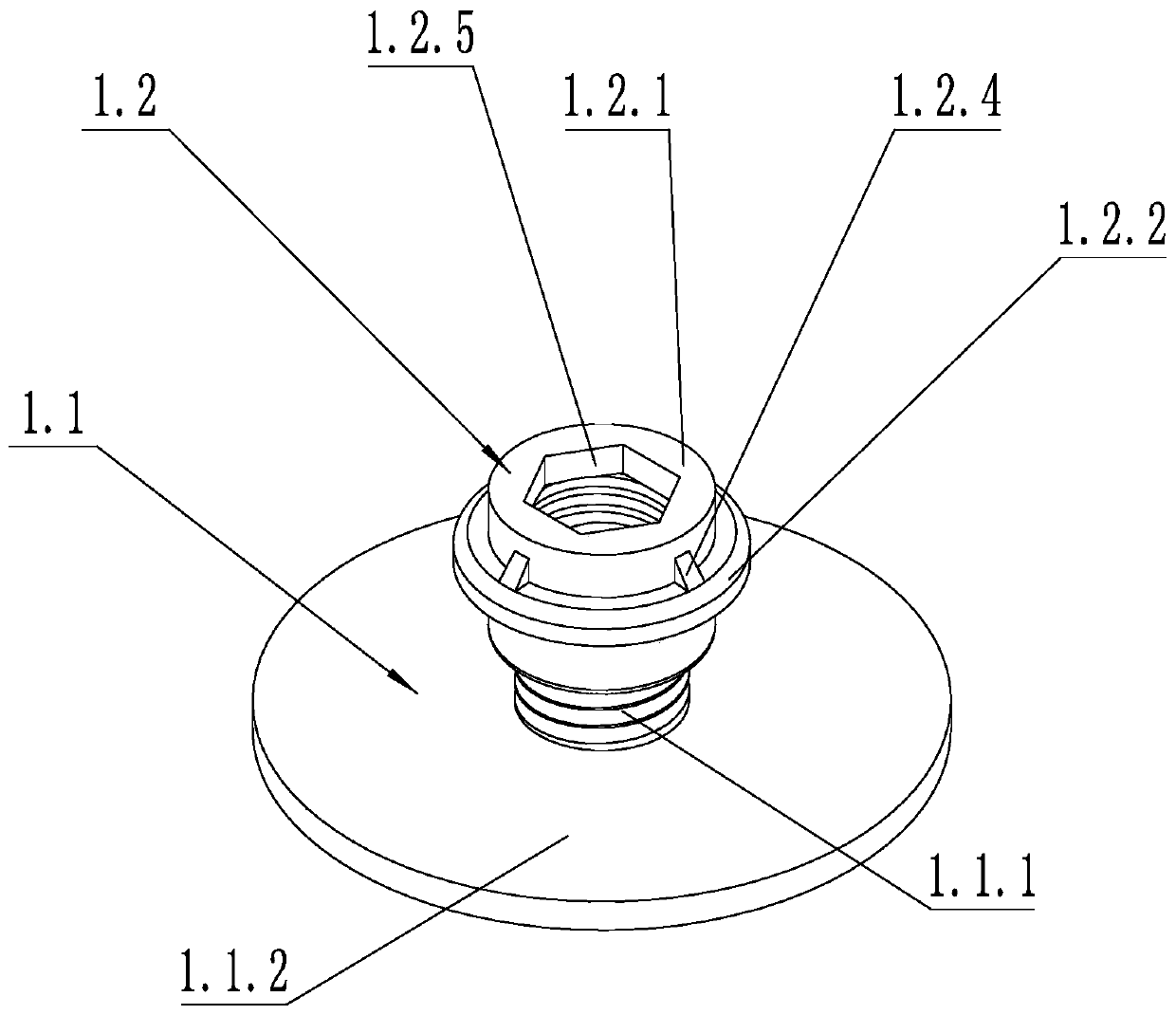

[0043] Such as figure 2 image 3 and Figure 4 As shown, on the basis of Example 1, the adjustment foot 1.1 is an integrally formed structure, the adjustment foot 1.1 includes a fixed column 1.1.1 and a chassis 1.1.2, the chassis 1.1.2 is a flat disc-shaped structure, and the chassis 1.1. One end surface of 2 is provided with a first reinforcing rib 1.1.5 distributed in a spoke shape and a second reinforcing rib 1.1.6 distributed in a rim shape; the fixing column 1.1.1 is fixed at the center of the other end surface of the chassis 1.1.2 In terms of position, the center of the fixed column 1.1.1 is provided with a fixed counterbore 1.1.3, the bottom of the fixed counterbore 1.1.3 is provided with a fixed through hole 1.1.4, the fixed through hole 1.1.4 passes through the chassis 1.1.2, and the fixed column 1.1.1 The outer wall is provided with external threads. The regulator 1.2 is integrally formed. The regulator 1.2 includes an adjusting column 1.2.1 and a ring-shaped fix...

Embodiment 3

[0046] Such as Figure 6 and Figure 7 As shown, on the basis of Embodiment 1, the flat connector 3 includes a second fixing groove 3.1 for connecting the leveling assembly 1 and two third panel slots 3.2 for connecting the veneer 5, the second fixing groove 3.1 is eccentrically arranged between the two third panel slots 3.2, the opening directions of the two third panel slots 3.2 are opposite, the opening direction of the second fixing slot 3.1 is perpendicular to the opening direction of the third panel slot 3.2; the third panel slot 3.2 is surrounded by the upper rib 3.3 of the third slot, the middle rib 3.4 of the third slot and the lower rib 3.5 of the third slot which are connected sequentially; Article 3.11, the upper rib 3.3 of the third slot is provided with a second fixing protrusion 3.12 pressed against the veneer 5, the second fixing protrusion 3.12 faces the lower rib 3.5 of the third slot, the shape of the second fixing protrusion 3.12 is class triangle.

[00...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com