Pipeline safety status assessment method and step-up booster pipeline safety resumption method

A safety state assessment and safety state technology, applied in the direction of pipeline system, pipe/pipe joint/fitting, pipe components, etc., can solve problems such as cracked pipes, pipe bursts, differences between simulated working conditions and actual engineering results, and achieve short time , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0068] The present invention will be further described below in conjunction with the accompanying drawings and embodiments. It should be noted that, in the case of no conflict, the embodiments in the present application and the technical features in the embodiments can be combined with each other.

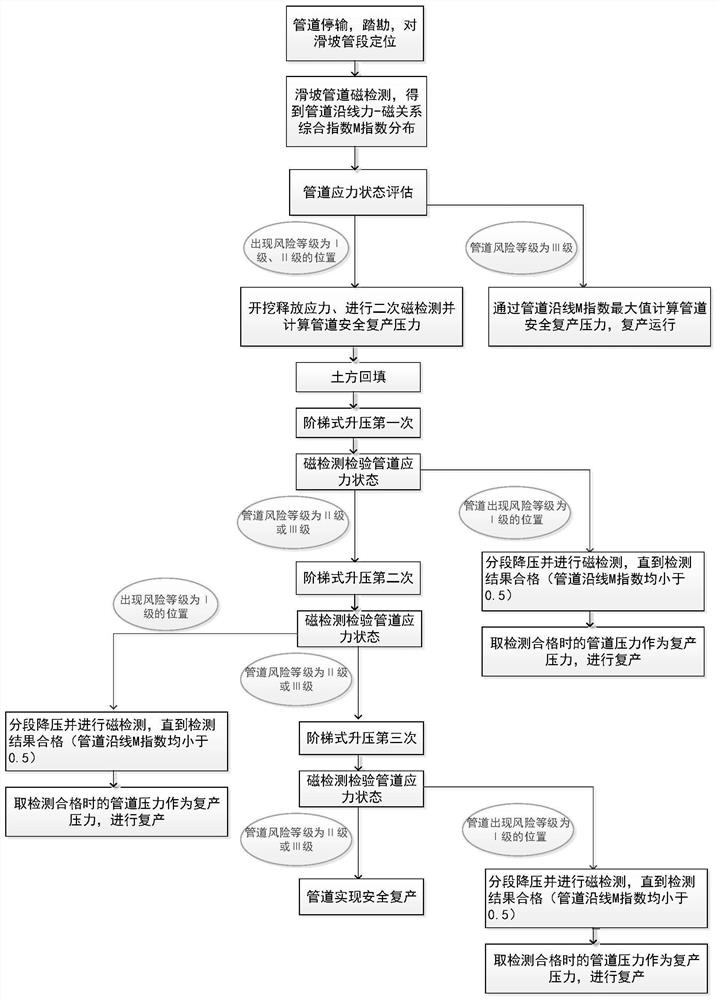

[0069] On the one hand, the present invention provides a kind of pipeline safety status assessment method, comprises the following steps:

[0070] S1: Stop the pipeline, survey and locate the landslide pipeline.

[0071] In a specific embodiment, locating the landslide pipeline includes: determining the length of the landslide pipeline and measuring its distance, and marking the start point and end point of the landslide pipeline.

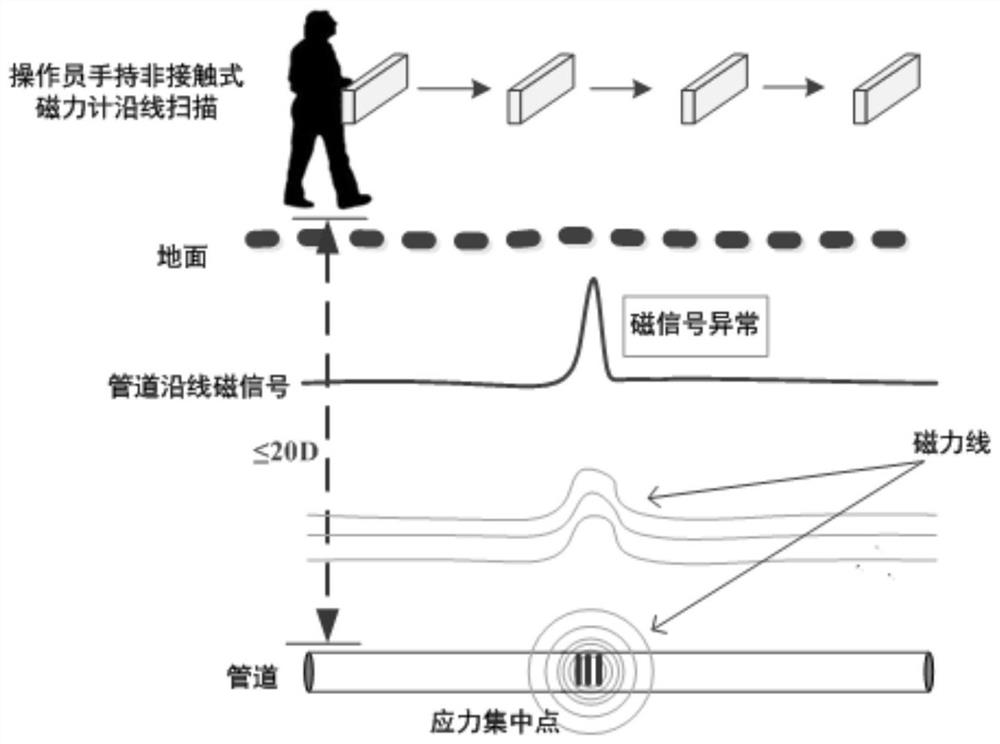

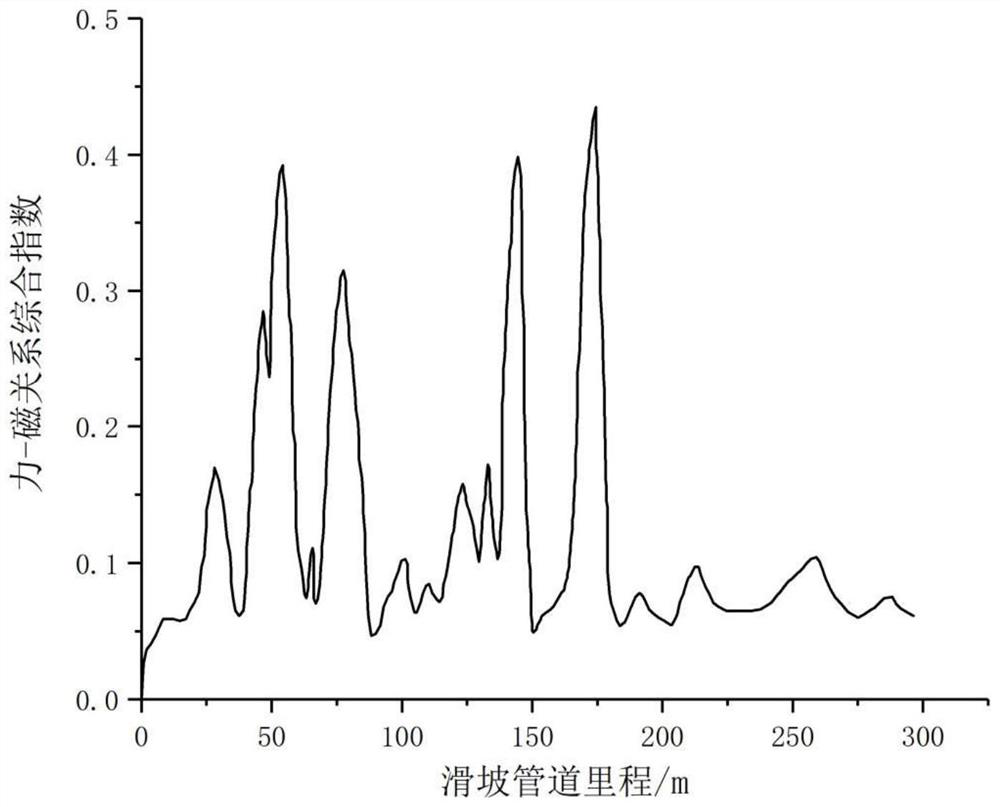

[0072] S2: Conducting magnetic detection on the landslide pipeline with a non-contact magnetometer, and using the non-contact magnetometer supporting software to observe and record magnetic signal data along the landslide pipeline.

[0073] In a speci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com